Dual-porous alumina carrier, demetallization catalyst and preparation method thereof

A technology of alumina carrier and double pores, which is applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problem of lower carrier utilization and reaction molecules staying in pores Short time in the channel, large pore size, etc., to achieve the effects of improving permeability, facilitating mass transfer and diffusion, and high metal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 500 grams of pseudoboehmite A1 (produced by Wenzhou Jingjing Alumina Co., Ltd., with a weight content of 70% on a dry basis) and roast at 450°C for 6 hours to prepare alumina.

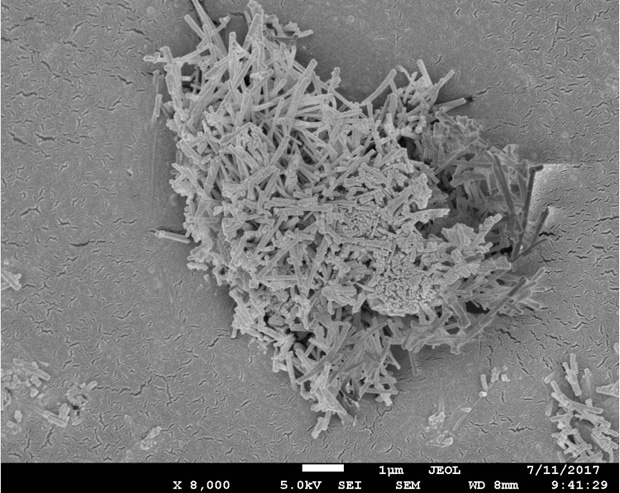

[0036] Weigh 50 grams of the above-mentioned alumina and place it in 250 grams of ammonium bicarbonate aqueous solution with a mass concentration of 12%, transfer the mixed material into an autoclave, seal it, heat it at 140°C for 6 hours, and then dry the carrier at 110°C for 6 hours. The aluminum oxide was submerged in a 25% polyethylene glycol-6000 (molecular weight: 6000) solution for 1.5 hours, and then the carrier was dried at 120°C for 6 hours to obtain rod-shaped alumina clusters.

[0037] Weigh 120 grams of pseudo-boehmite A1 (manufactured by Wenzhou Jingjing Alumina Co., Ltd., with a dry weight content of 70%), 30 grams of the above-mentioned rod-shaped alumina clusters, and 1.5 grams of scallop powder, and mix the above-mentioned materials evenly. Add an appropriate amount of aq...

Embodiment 2

[0039] Same as Example 1, except that the calcination temperature of pseudo-boehmite is 550°C. The consumption of ammonium bicarbonate solution is 200 grams, and the mass concentration of solution is 15%. The heat treatment temperature was 160° C., and the treatment time was 4 hours. The polyethylene glycol-6000 solution was changed to polyethylene glycol-2000 (that is, the molecular weight is 2000) solution, and the mass concentration was 30%. The amount of rod-shaped alumina clusters added was 24 grams, and the dual-porous alumina carrier A2 of the present invention was obtained. The properties of the carrier are shown in Table 1.

Embodiment 3

[0041] Same as Example 1, except that the roasting temperature of pseudo-boehmite is 500°C. The consumption of ammonium bicarbonate solution is 400 grams, and the mass concentration of solution is 8%. The heat treatment temperature was 130° C., and the treatment time was 7 hours. The polyethylene glycol-6000 solution was changed to polyethylene glycol-12000 (that is, the molecular weight is 12000) solution, and the mass concentration was 20%. The amount of rod-shaped alumina clusters added was 42 grams, and the dual-porous alumina carrier A3 of the present invention was obtained. The properties of the carrier are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com