A kind of high temperature resistant structural wave absorbing material based on metal coating and its preparation method

A technology of wave absorbing material and metal coating, applied in the field of wave absorbing material, can solve the problem of large change of wave absorbing performance with temperature rise, and achieve the effect of realizing impedance matching design, low dielectric constant, and meeting the needs of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

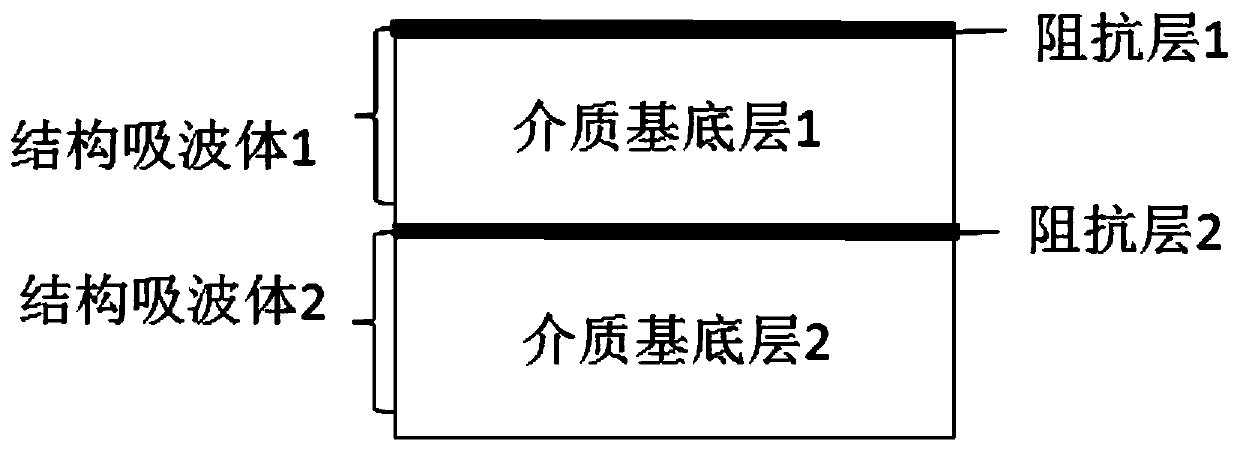

[0037] A kind of high temperature resistant structural wave absorbing material based on metal coating of the present invention, such as figure 1 As shown, it is composed of two sets of structural absorbers. The structural absorber includes a dielectric base layer and an impedance layer from bottom to top. The dielectric base layer is a silica fiber reinforced silica airgel composite material. The resistance layer is quartz fiber cloth coated with nickel-chromium alloy. Its preparation method comprises the following steps:

[0038] (1) Preparation of medium substrate: select quartz fiber reinforced silica airgel composite material according to design requirements, prepare quartz fiber reinforced silica airgel composite material by sol-gel process, and finally, use mechanical processing method to make the composite The material is processed to 7.5mm to make 7.5mm thick dielectric base layer 1 and dielectric base layer 2;

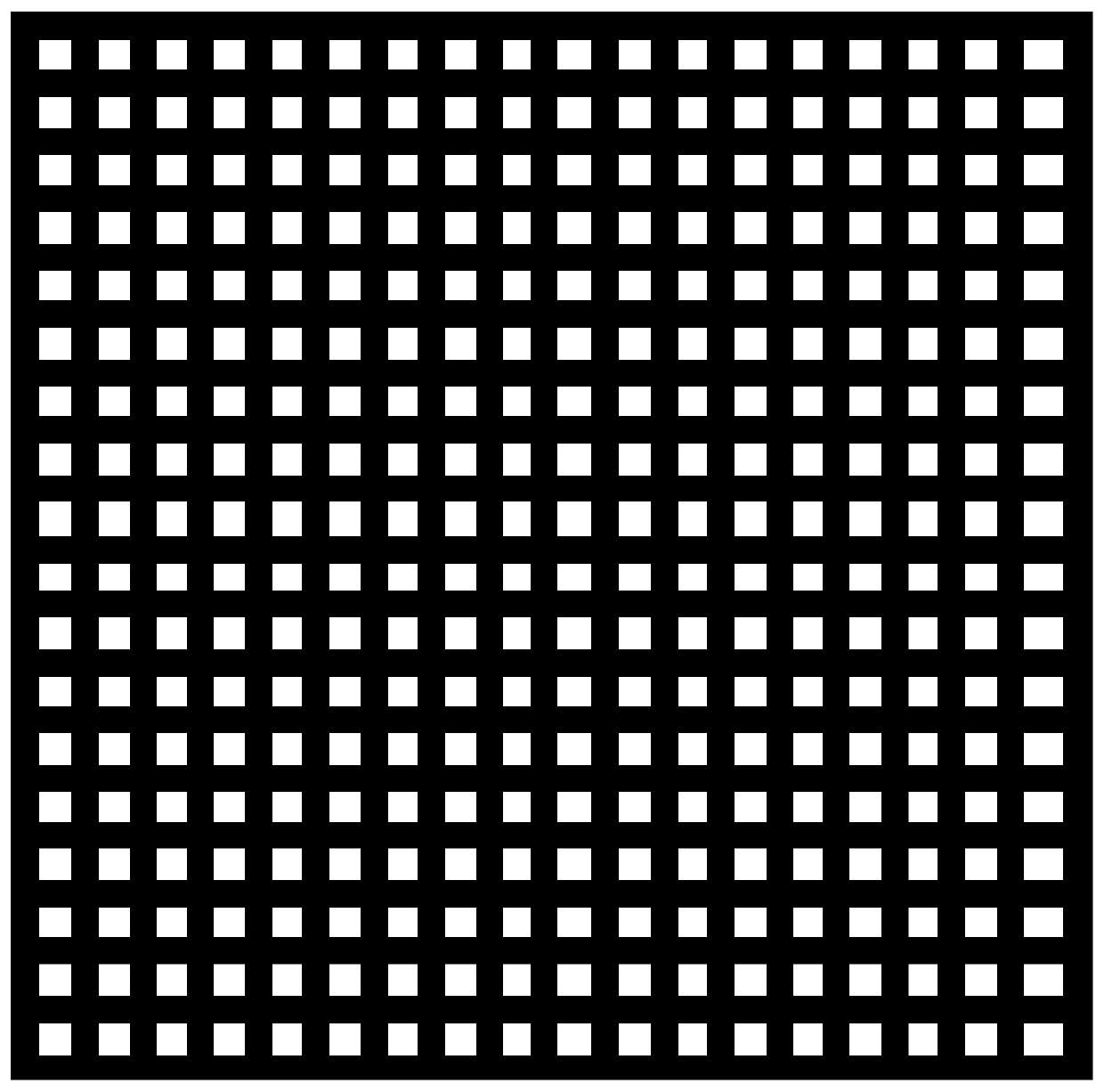

[0039] (2) Preparation of impedance layer: Using the ...

Embodiment 2

[0045] A metal coating-based high-temperature-resistant structural wave-absorbing material of the present invention is composed of a group of structural wave-absorbing bodies, and the structural wave-absorbing body includes a dielectric base layer and an impedance layer from bottom to top, and the dielectric base layer It is a continuous mullite fiber reinforced silicon oxide airgel composite material, and the resistance layer is a boron nitride fiber cloth coated with nickel-chromium-iron alloy. Its preparation method comprises the following steps:

[0046] (1) Preparation of medium substrate: Select quartz fiber-reinforced silica airgel composite material according to the design requirements, and prepare continuous mullite fiber-reinforced silica airgel composite material by sol-gel process, and finally, adopt mechanical processing method , process the composite material to 7.5mm to make a 7.5mm thick dielectric base layer;

[0047] (2) Preparation of impedance layer: The mag...

Embodiment 3

[0052] A kind of high temperature resistant structural wave absorbing material based on metal coating of the present invention, such as figure 1 As shown, it is composed of two sets of structural absorbers. The structural absorber includes a dielectric base layer and an impedance layer from bottom to top. The dielectric base layer is a silica fiber reinforced silica airgel composite material. The resistive layer is silicon carbide fiber cloth coated with Ni-Cr-Nd alloy. Its preparation method comprises the following steps:

[0053] (1) Preparation of medium substrate: select quartz fiber reinforced silica airgel composite material according to the design requirements, prepare quartz fiber reinforced silica airgel composite material by sol-gel process, and finally, use mechanical processing method to make the composite The material is processed to 5mm to make a dielectric base layer 1 and a dielectric base layer 2 with a thickness of 5 mm;

[0054] (2) Preparation of impedan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com