Production method of heat-stable ceramic mold

A ceramic mold and thermal stability technology, which is applied in the production of ceramic materials, clay products, household appliances, etc., can solve the problems of poor thermal stability, high thermal expansion coefficient, unstable size, etc., and achieve good thermal stability, low thermal expansion coefficient, Dimensional stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

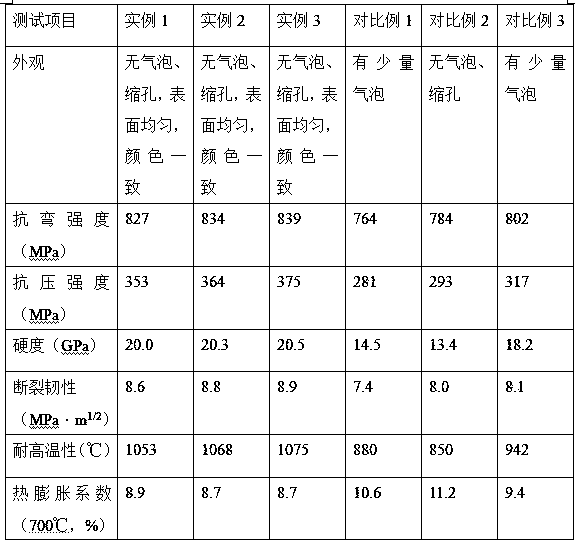

Examples

preparation example Construction

[0027] Preparation of modified glass fiber: mix glass fiber, chloroacetic acid solution with a mass fraction of 25%, isopropanol, and sodium hydroxide solution with a mass fraction of 10% in a mass ratio of 7:3:4:1, and then put into a beaker, and blow nitrogen into the beaker until all the air is replaced. Under the protection of nitrogen, heat up to 40°C, stir and react for 30 minutes, and obtain modified glass fibers.

[0028] Preparation of modified inorganic substances: collect kaolin, put it into a pulverizer, pulverize it for 1 hour, then put it into a grinder, and grind it for 1 hour to obtain kaolin powder. The kaolin powder and the above-mentioned modified glass fiber are mixed in a mass ratio of 2 : 1 mixed to obtain the fermentation substrate, put the fermentation substrate into the fermenter, then add river bottom sludge with 7% of the fermentation substrate mass and 5% distilled water of the fermentation substrate mass to the fermenter, seal and ferment for 1 week...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com