A kind of preparation method of red algae-based biomass flame retardant coating

A flame retardant coating and biomass technology, applied in fire retardant coatings, epoxy resin coatings, coatings, etc., can solve the problems of easy migration, affecting the flame retardant efficiency of intumescent flame retardants, and easy moisture absorption and agglomeration of ammonium polyphosphate. Achieve the effect of improving compatibility, wide application range, and increasing flame retardant and smoke suppression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

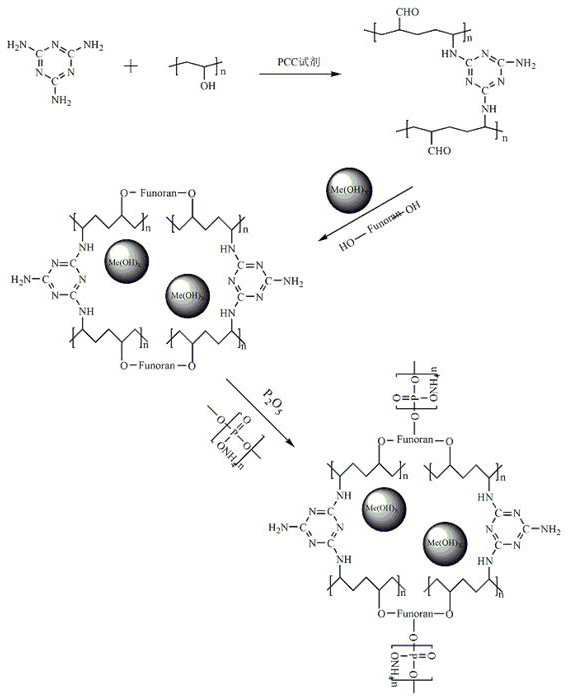

[0023] A novel red algae-based biomass flame-retardant coating and a preparation method thereof, characterized in that the method is that the flame-retardant coating is made of microcapsules coated with nanometer metal hydroxide and melamine by connecting red algae-based biomass with melamine Ammonium polyphosphate is grafted and then compounded with water-based epoxy resin. The specific synthesis steps are as follows:

[0024] Step 1: Dissolve 12g of polyvinyl alcohol and 6g of melamine in 40ml of distilled water, add it to a 500ml three-necked bottle, adjust the pH of the solution to 4.5 with a 5% hydrochloric acid solution, raise the temperature to 90°C, and stir at 300-400r / min for 2.5h. Use 10% sodium carbonate solution to adjust the pH to 7.5, add an oxidizing agent, and react for 0.5h. Under the condition of 4500r / min with distilled water, centrifuge washing 3 times, and dry at 60°C for 12h to obtain melamine modified by oxidized polyvinyl alcohol.

[0025] Step 2: Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com