Lithium ion battery cathode material and preparation method thereof, and application thereof

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing high-nickel ternary cathode materials, reducing the magnetic properties of cathode materials, etc., to achieve good body consistency, easy to powder Body processing, the effect of suppressing the generation of magnetic impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

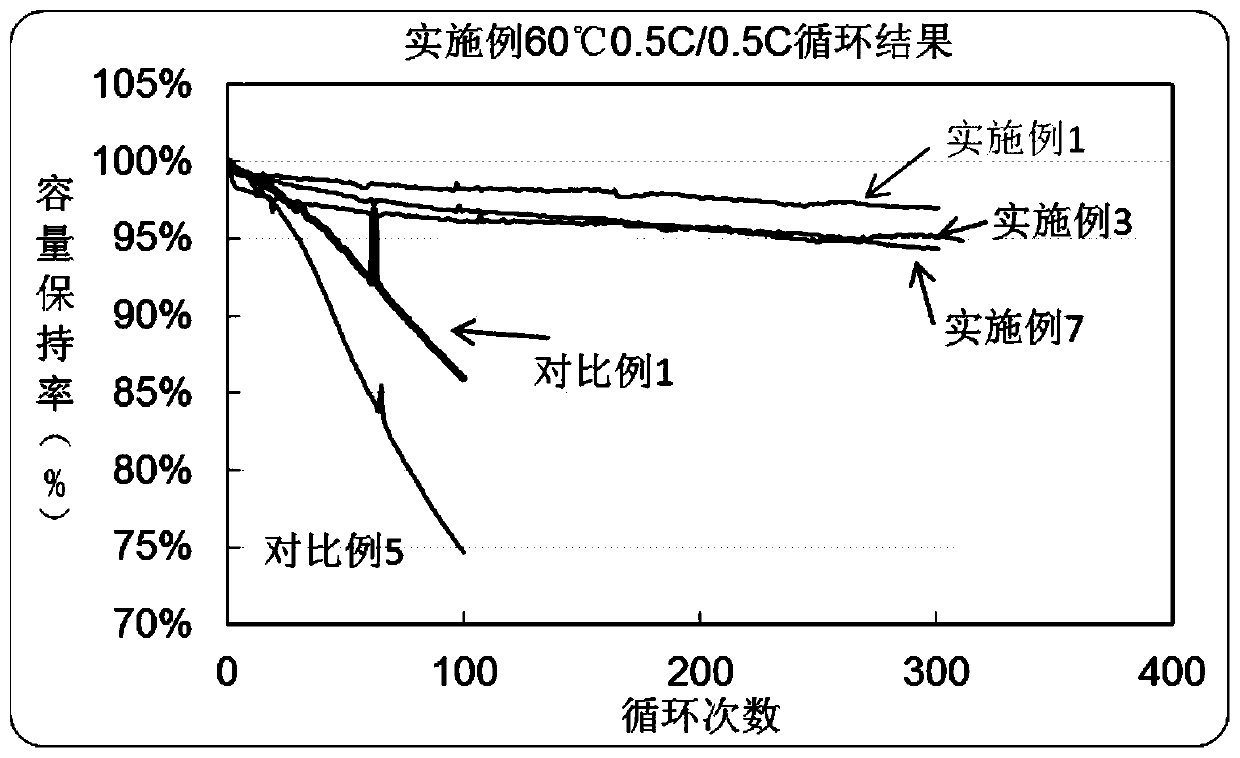

Examples

preparation example Construction

[0055] In a preferred embodiment, the present invention provides a positive electrode material with low magnetic impurities and its preparation method, which is characterized in that: a surface lithium-rich positive electrode material is generated on the surface of the semi-finished product during the synthesis stage, and the strong magnetic The substance is transformed into a low magnetic substance.

[0056] Preferably, the above-mentioned positive electrode material is characterized in that: the structural formula of the material is Li x Ni a co b mn c m d o 2 Among them, R is a doping element, 0.95<x<1.15, 0.60<a<0.95, 0<b<0.2, 0<c<0.3, 0.98≤a+b+c≤1.00, wherein manganese (Mn) can be Aluminum element (Al) is substituted, corresponding to the content of aluminum element: 0<c<0.08.

[0057] Preferably, the preparation process of the above-mentioned positive electrode material comprises the following steps:

[0058] (1) Mix raw materials including the first lithium sourc...

Embodiment 1

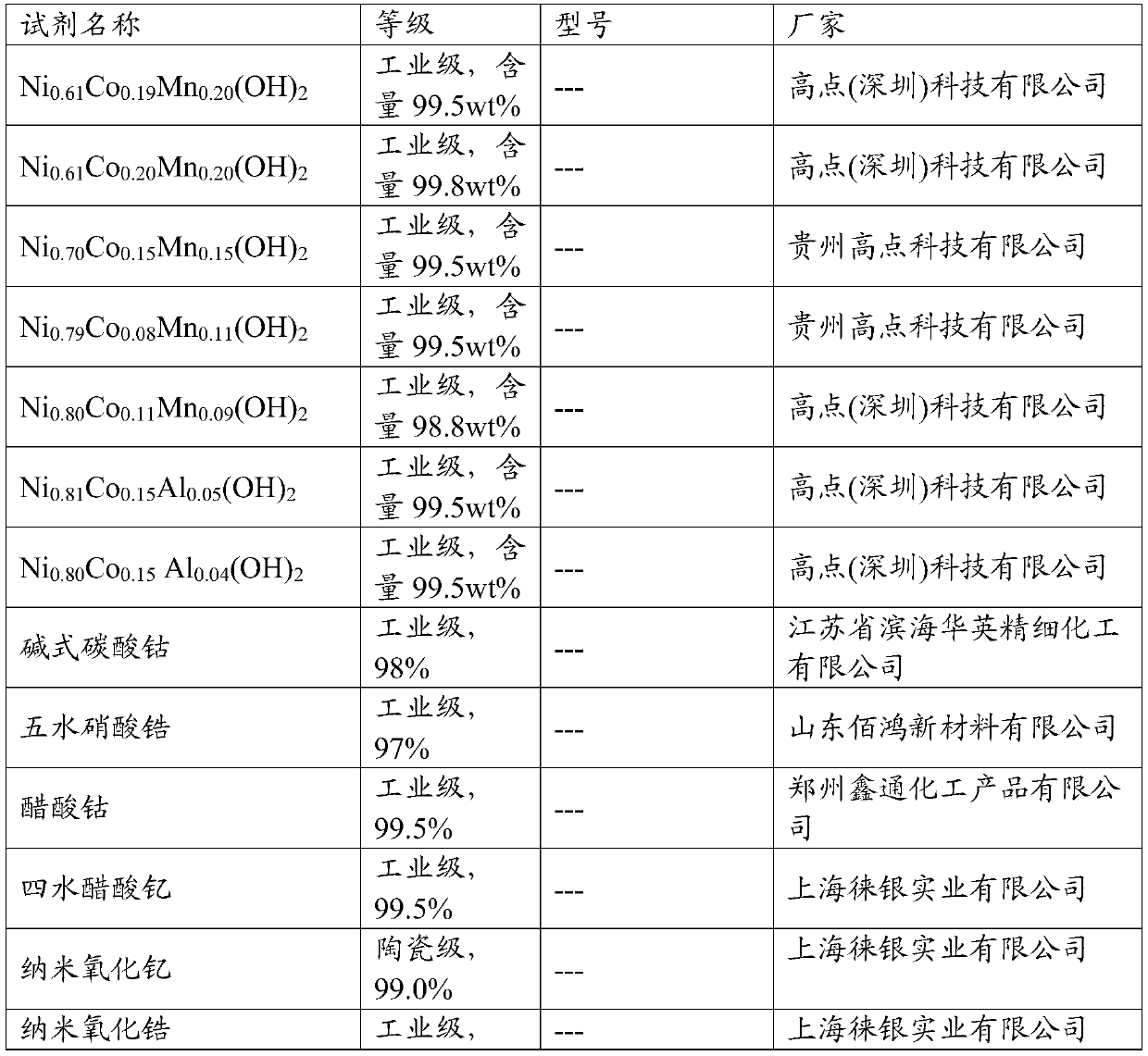

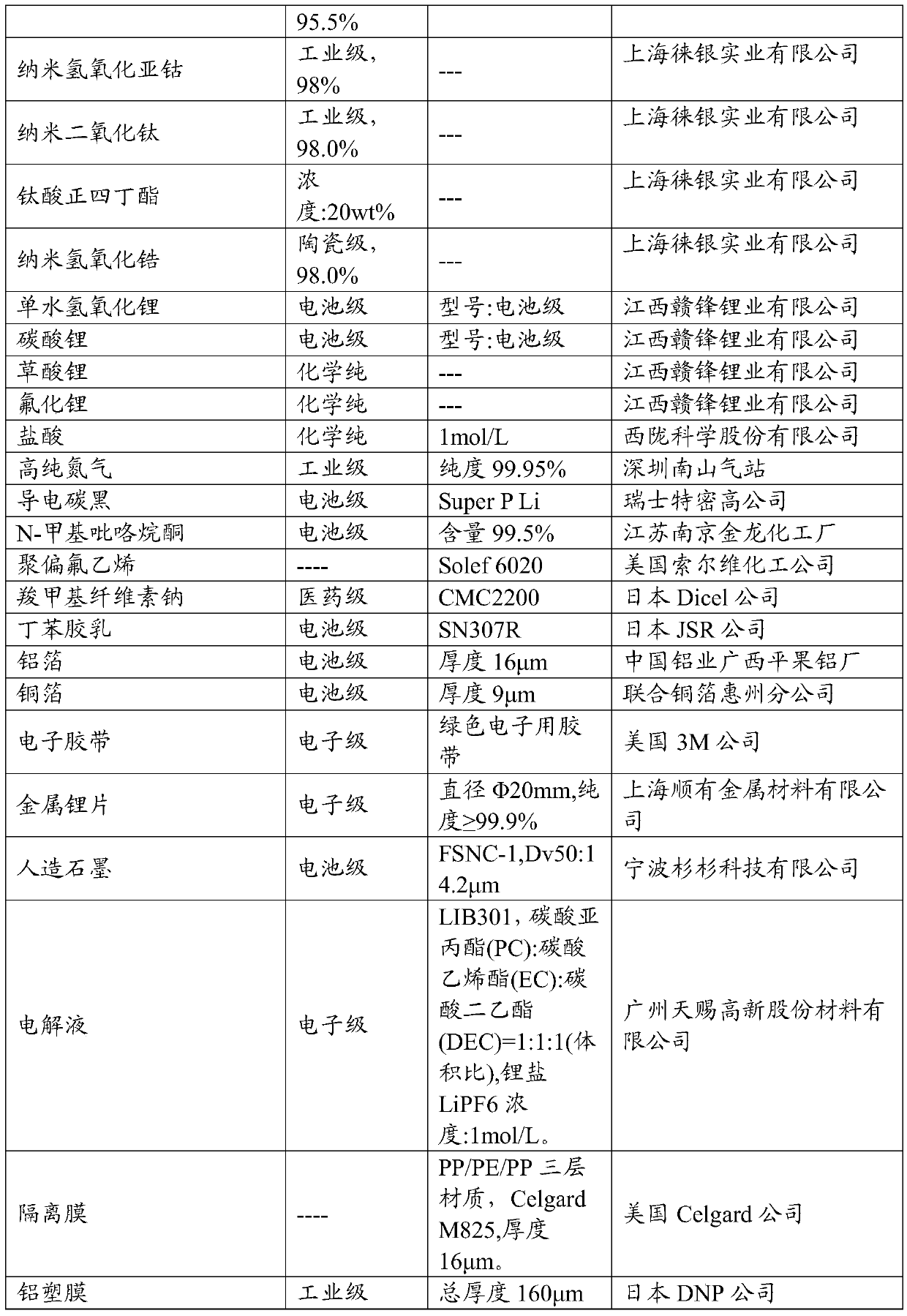

[0085] Material mixing: use 200L plow mixer. Turn on stirring (speed 25rpm), add 100kg of nickel-cobalt-manganese precursor (Ni 0.61 co 0.19 mn 0.20 (OH) 2 (grain size D v50 : 7 μm, effective substance content 99.5%), then take by weighing 46.1kg monohydrate lithium hydroxide powder (particle size D v50 : 25 μm, active substance content 98.5%) join in mixer, add 37.0kg deionized water by 80wt% solid content under stirring situation, then add 1.43kg basic cobalt carbonate (account for 7000ppm by adding and cobalt amount according to finished product) After stirring for 2 hours, further reduce the speed (5rpm) and stir for 6 hours to form a paste-like material with a certain degree of molding and seal it for later use.

[0086] Primary sintering: use ventilated 24m roller kiln. Set the temperature in the heating zone to 400°C, under the condition of introducing oxygen-enriched air (oxygen-enriched air with an oxygen content of 45%, and a flow rate of 500Nm 3 / h) Put the m...

Embodiment 2

[0093] Material mixing: use 200LY mixer. Start stirring (rotating speed 50rpm), add the nickel-cobalt-manganese precursor (Ni 0.61 co 0.20 mn 0.20 (OH) 2 (grain size D v50 : 7 μm, effective substance content 99.5%), then take by weighing 41.5kg lithium carbonate powder (particle size D v50 : 5 μm, active ingredient content 98.8%) into the mixer, add 20.0kg deionized water according to 90% solid content under stirring, and 7.45kg n-tetrabutyl titanate (industrial grade, active ingredient content 20%, content The titanium content in the finished product is 2000ppm), after stirring for 2 hours, further reduce the speed (5rpm) and stir for 1 hour to form a paste-like material with a certain degree of molding, which is discharged and sealed for later use.

[0094] Primary sintering: adopt the method similar to embodiment 1 to carry out primary sintering (sintering temperature 700 ℃, oxygen content of oxygen-enriched air 99.5%, flow 300Nm 3 / h), embodiment 2 loss on ignition i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com