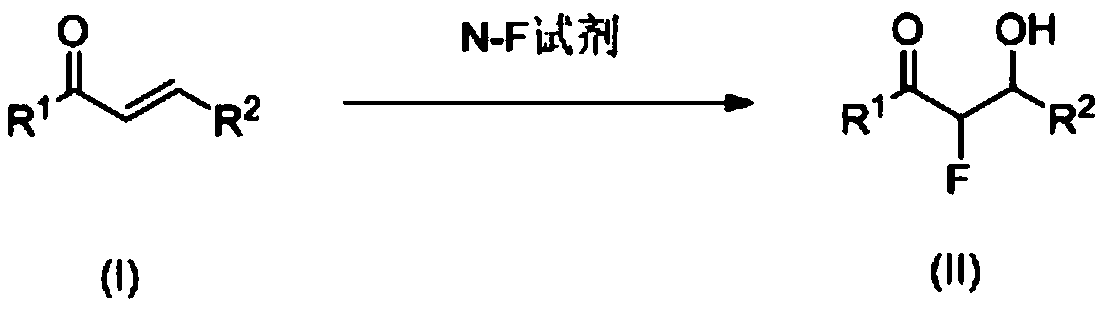

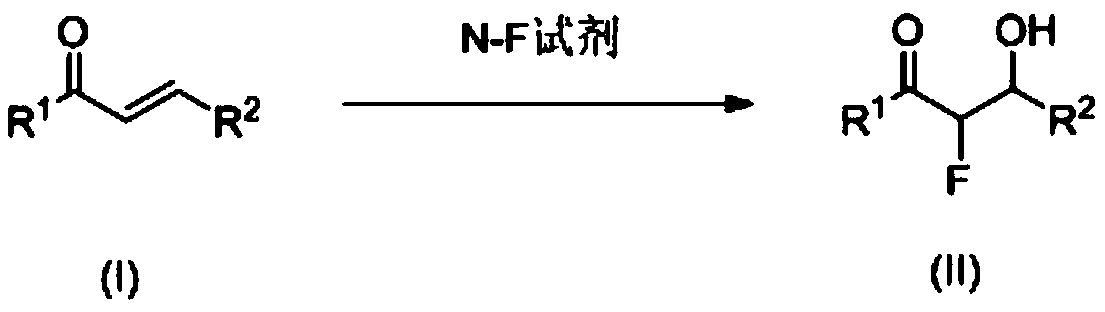

Synthesis method of alpha-F-beta-OH-carbonyl compound

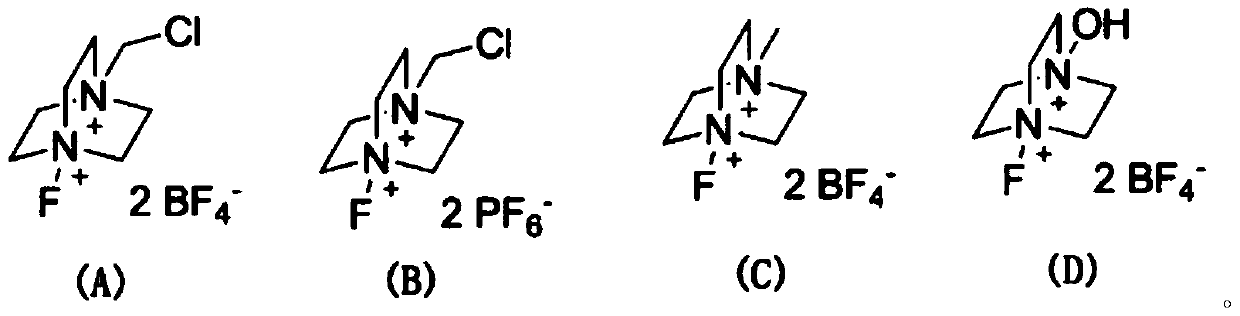

A technology of carbonyl compounds and synthesis methods, which is applied in the field of synthesis of α-F-β-OH-carbonyl compounds, can solve the problems of unsaturated ketone fluorination and hydroxylation, expensive transition metals, large fluorine-containing reagents, etc., and achieve Substrate applicability Economic and environmental protection, good substrate applicability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Chalcone (1mmol, 208mg) and Selectfluor (1.0mmol, 247mg) were added to a 25mL single-port reaction flask, and a mixture of acetonitrile and water with a volume ratio of 20:1 was added as a reaction solvent (reaction solvent addition was 7.35mL ), warming up to 40°C for 12h. After the reaction, the reaction solution was washed with water, extracted with dichloromethane, and separated into an organic layer and an aqueous layer. After the organic layer was dried over anhydrous sodium sulfate, it was concentrated by vacuum distillation to remove the solvent to obtain a yellow oil. The yellow oil was separated by column chromatography, using a mixture of petroleum ether and ethyl acetate at a volume ratio of 20:1 as the eluent, collecting the eluate containing the target compound, distilling off the solvent and drying to obtain 112 mg of white solid 2-fluoro- 3-Hydroxy-1,3-diphenylpropan-1-one, the yield is 46%, the chemical structural formula is:

[0030]

[0031] Chara...

Embodiment 2

[0033] The reaction time was shortened to 8 h, and the other operating conditions were the same as in Example 1. Finally, 90 mg of white solid 2-fluoro-3-hydroxy-1,3-diphenylpropan-1-one was obtained with a yield of 37%.

Embodiment 3

[0035] The reaction solvent was replaced with a mixed solvent of acetonitrile and water with a volume ratio of 50:1, the amount of the reaction solvent added was 7.14 mL, and other operating conditions were the same as in Example 1, finally obtaining 122 mg of white solid 2-fluoro-3-hydroxyl-1, 3-Diphenylpropan-1-one, yield 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com