Core-shell waterborne polyurethane/acrylic ester composite emulsion, preparation method thereof and damping paint of emulsion

A water-based polyurethane and acrylate technology, applied in the field of coatings, can solve the problems of poor stability of composite emulsion, poor compatibility of polyurethane and acrylate, poor damping performance, etc., and achieve the effect of reducing production costs, excellent damping performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

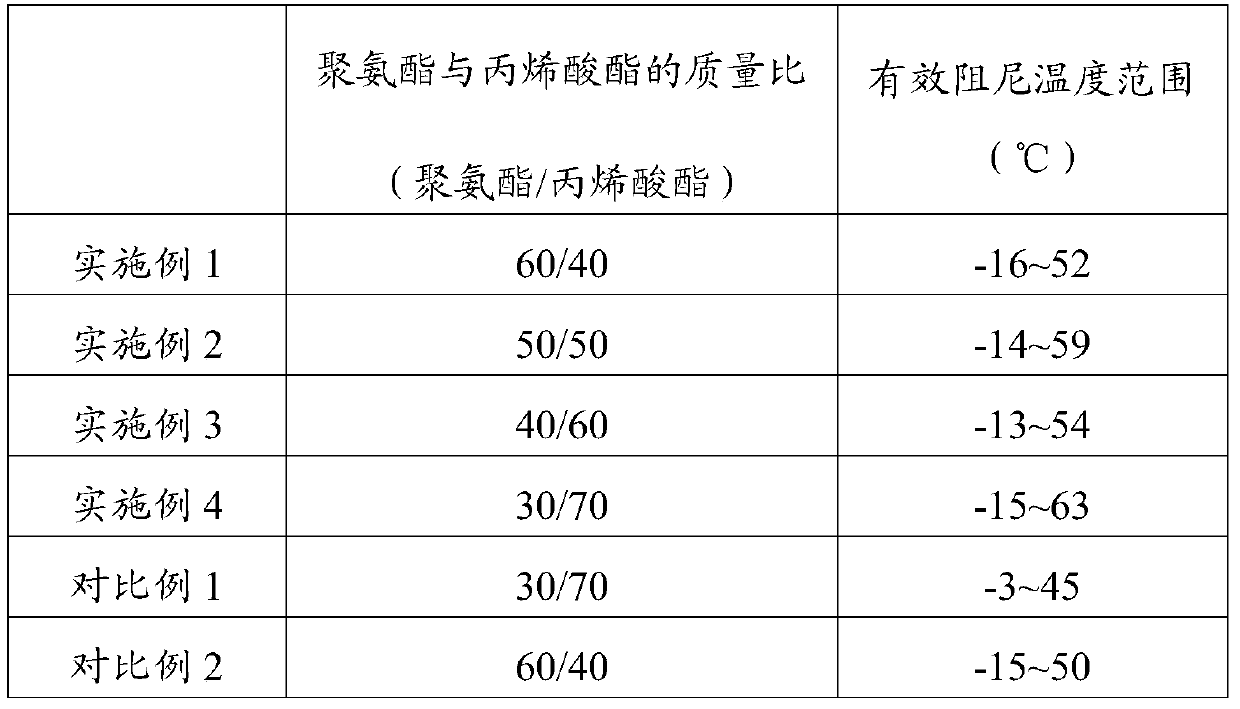

Examples

preparation example Construction

[0060] The present invention provides a preparation method of the core-shell type waterborne polyurethane / acrylate composite emulsion according to the above scheme, which includes the following steps:

[0061] (1) Mix oligomer diols, polyisocyanates, small molecular alcohol chain extenders, hydrophilic chain extenders, small molecular crosslinkers, organic solvents and catalysts to undergo polycondensation to obtain isocyanate-terminated polyurethane pre Aggregate

[0062] (2) Mixing the isocyanate-based polyurethane prepolymer in the step (1) with the blocking agent to cause a polycondensation reaction to obtain a waterborne polyurethane prepolymer;

[0063] (3) Mixing the water-based polyurethane prepolymer with part of acrylate monomers and a salt-forming agent to undergo a neutralization reaction to obtain a water-based polyurethane emulsion;

[0064] (4) Mixing the water-based polyurethane emulsion with the remaining acrylate monomers, emulsifiers, cross-linking agents, initiator...

Embodiment 1

[0092] (1) In a four-neck flask equipped with a stirring device, a condensing device, a thermometer and a nitrogen protection, add 60g polyethylene glycol (number average molecular weight is 2000), and vacuum dehydration at 70℃ for 2h, the vacuum degree is less than 0.1MPa, then add 37.5g isophorone diisocyanate, 5.6g 1,4-butanediol, 6.8g dimethylolpropionic acid, 2g trimethylolpropane, 11.3gN,N-dimethylol Acetamide and 60mg dibutyltin dilaurate, raise the system to 80°C at a heating rate of 5°C / min, and perform a polycondensation reaction at a stirring speed of 370r / min for 1 hour to obtain an isocyanate-terminated polyurethane prepolymer;

[0093] (2) After the isocyanate-terminated polyurethane prepolymer is obtained, 12.9g of hydroxyethyl acrylate is added, and the polycondensation reaction is carried out at a stirring speed of 370r / min and 80°C for 1h to obtain a waterborne polyurethane prepolymer;

[0094] (3) After the water-based polyurethane prepolymer is obtained, the wat...

Embodiment 2

[0098] Prepare the water-based polyurethane prepolymer according to the method of step (1) and (2) in Example 1, which will not be repeated here;

[0099] (3) After the water-based polyurethane prepolymer is obtained, the water-based polyurethane prepolymer system is cooled to 40°C at a cooling rate of 5°C / min, and 15g methyl methacrylate and 45g butyl acrylate are added to reduce the viscosity of the system. System-NCO value reaches 0, add 4.4g of triethylamine, carry out the neutralization reaction at a stirring speed of 370r / min for 10min, then slowly add 200mL of deionized water at a speed of 200ml / min, at a speed of 1200r / min , Emulsify at room temperature for 30 minutes to obtain an aqueous polyurethane emulsion;

[0100] (4) After the water-based polyurethane emulsion is obtained, the system temperature of the water-based polyurethane emulsion is increased to 75°C at a temperature increase rate of 5°C / min, and stirred at a rotation speed of 270r / min for 15 minutes to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com