Amphiphilic peptide block copolymer containing porphyrin end group and its preparation method and application

A block copolymer and amphiphilic technology, which is applied in the field of amphiphilic temperature-sensitive polypeptide hybrid block copolymer and its preparation, which can solve the limitation of research on polypeptide hybrid block copolymer and product distribution index. Wide and small molecular weight, etc., to achieve the effect of large application potential, narrow distribution index and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] i) The preparation process of the oil-soluble polypeptide is:

[0059]

[0060] Wherein, n=50-100; preferably, n=100.

[0061] Using L-glutamic acid-γ-benzyl ester-N-carboxy-cyclic acid anhydride as raw material, in organic solvent, 5-(4-aminophenyl)-10,15,20-triphenylporphyrin as Initiator, the reaction temperature is controlled at 20-40°C, and the reaction time is 72-96 hours; preferably, the reaction temperature is 25°C, and the reaction time is 72 hours. Then react with azidobutyric acid, the reaction temperature is controlled at 60-80°C, and the reaction time is 72-96 hours, preferably, the reaction temperature is 70°C, and the reaction time is 84 hours. The oil-soluble polypeptide represented by formula (a) is obtained.

[0062] Among them, the raw materials L-glutamic acid-γ-benzyl ester-N-carboxy-cyclic anhydride, 5-(4-aminophenyl)-10,15,20-triphenylporphyrin, azidobutyric acid The molar ratio is 50-100:1:1.5; preferably, it is 100:1:1.5.

[0063] Wherein...

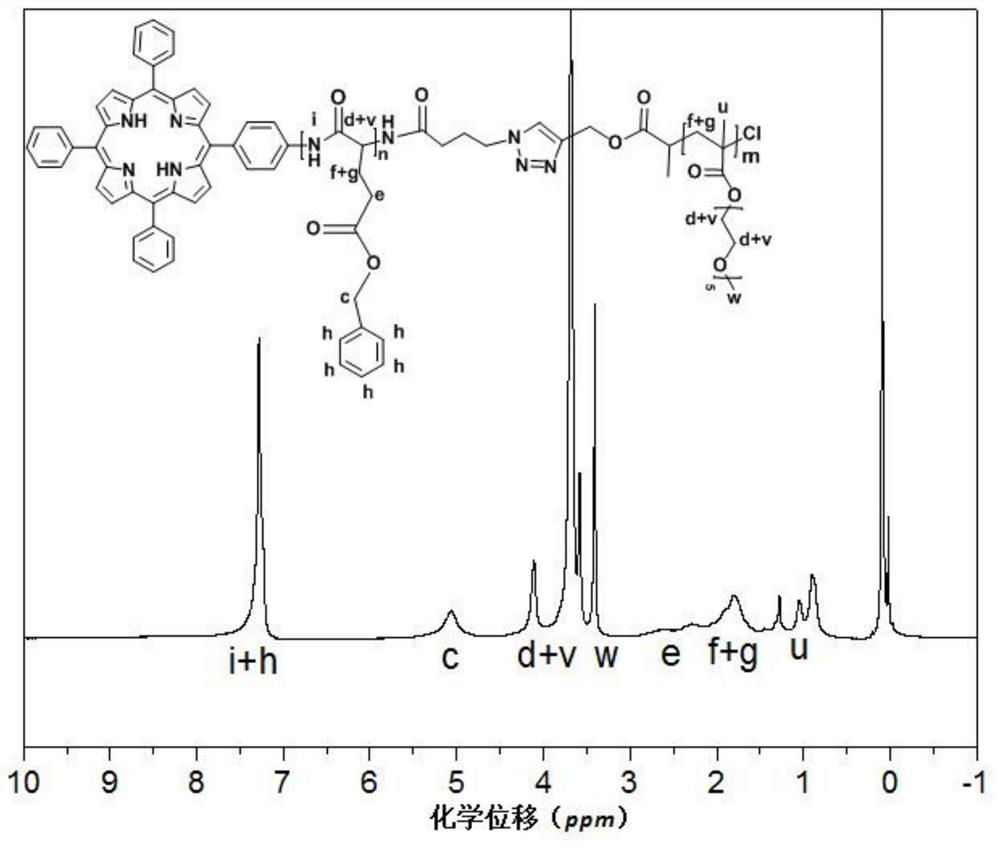

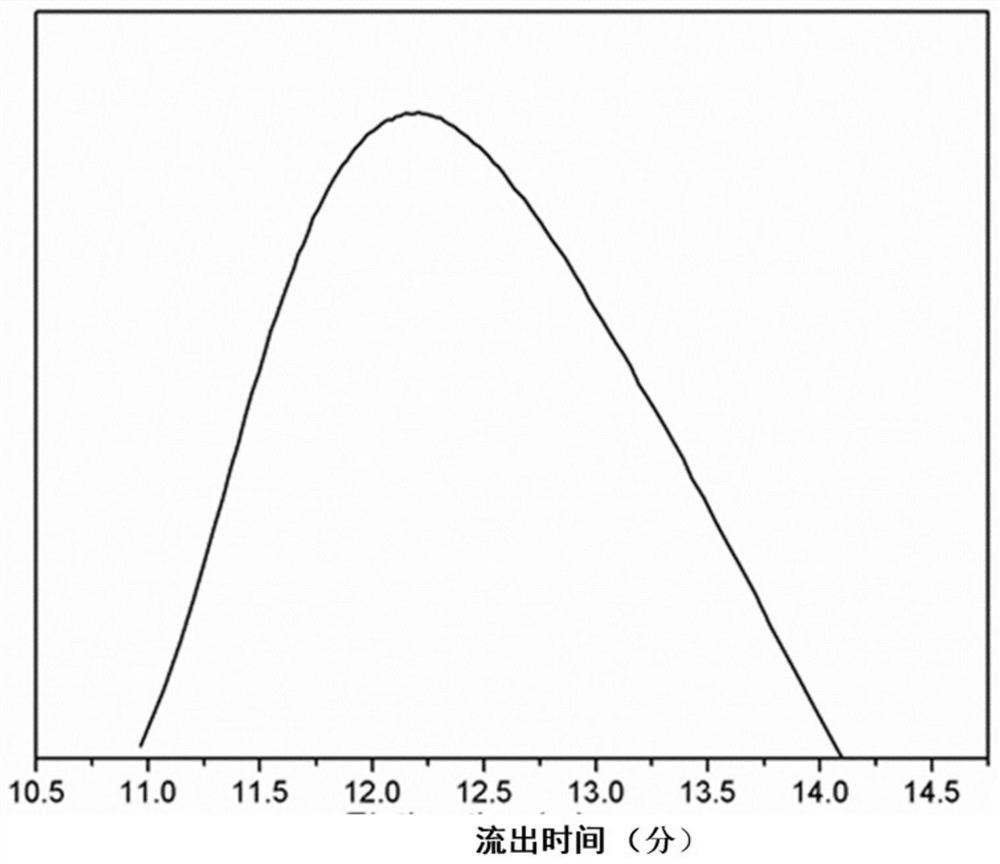

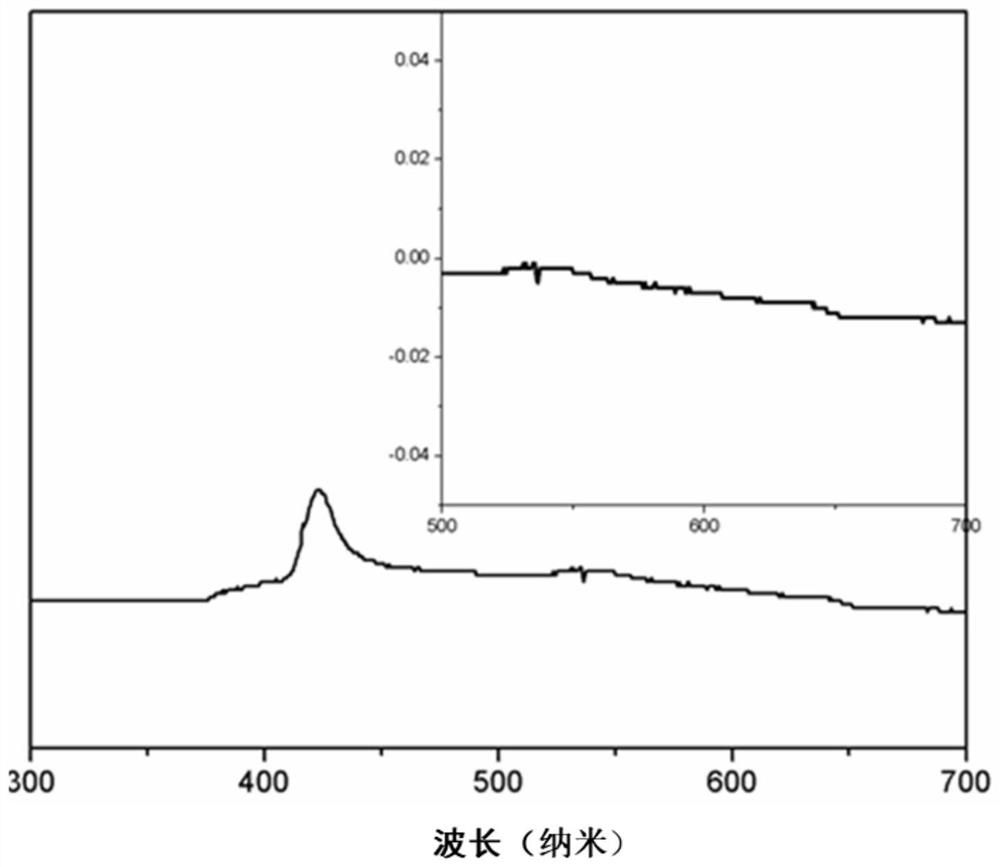

Embodiment 1

[0078] Preparation of Amphiphilic Polypeptide Block Copolymers Containing Porphyrin Terminal Groups

[0079] Conversion of L-glutamic acid-γ-benzyl ester to monomeric L-glutamic acid-γ-benzyl ester-N-carboxy-cyclic anhydride via the triphosgene method to monomethyl ether polyethylene glycol methacrylate With L-glutamic acid-γ-benzyl ester-N-carboxyl-in-ring anhydride as a monomer, use atom transfer radical polymerization (ATRP), amino acid anhydride ring-opening polymerization (NCA-ROP), active Amidation reaction yielded a hydrophilic poly(monomethyl ether polyethylene glycol methacrylate) (PEGMA) temperature-sensitive homopolymer and a hydrophobic poly(L-glutamic acid-γ-benzyl ester) containing porphyrin end groups. ) (PBLG) homopolypeptide. Then click chemistry is used to link the two block chains to form an amphiphilic polypeptide block copolymer containing porphyrin end groups.

[0080] Under the protection of nitrogen, 6.02g (25.2mmol) of benzyl L-glutamate, 2.64g (8.4m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com