Titanium alloy composite material, preparation method thereof and laser additive manufacturing forming method

A composite material and laser additive technology, applied in the direction of additive processing, etc., can solve the problems of low hardness, poor wear resistance, unable to meet the requirements of metal matrix composite materials, etc., to improve the density, solve the processing difficulty, and eliminate the effect of cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The titanium alloy composite material of this embodiment is specifically prepared according to the following steps:

[0030] (1) Weighing Ti6Al4V powder, titanium carbide, titanium boride and titanium silicide which are respectively 99.5%, 0.2%, 0.2%, and 0.1% by weight, wherein the purity of Ti6Al4V powder is greater than 99.9wt%, and the average particle diameter is 15 μm, The purity of titanium carbide, titanium boride and titanium silicide is greater than 99.9wt%, and the average particle size is 40nm;

[0031] (2) Place the raw materials of step (1) in a planetary high-energy ball mill for ball milling. During the ball milling process, argon is used as the protective gas, and zirconia ceramic balls with a diameter of 2 mm are added as the ball milling medium. The zirconia ceramic balls The mass ratio of the ball mill to the raw material is 5:1. The ball mill is rotated in a combination of up and down and left and right rotation. The speed of the up and down turning...

Embodiment 2

[0035] The difference between the steps of preparing the titanium alloy composite material in this example and Example 1 is:

[0036] The weight percentages of Ti6Al4V, titanium carbide, titanium boride and titanium silicide are 80%, 5%, 10% and 5% respectively, the particle size of Ti6Al4V powder is 53μm, and the particle size of titanium carbide, titanium boride and titanium silicide is 200nm ;

[0037] The diameter of zirconia ceramic balls is 15mm, the mass ratio of zirconia ceramic balls to raw materials is 20:1, the rotation speed of the ball mill is 80rpm up and down, the rotation speed of left and right is 300rpm, and the total time of ball milling is 50h.

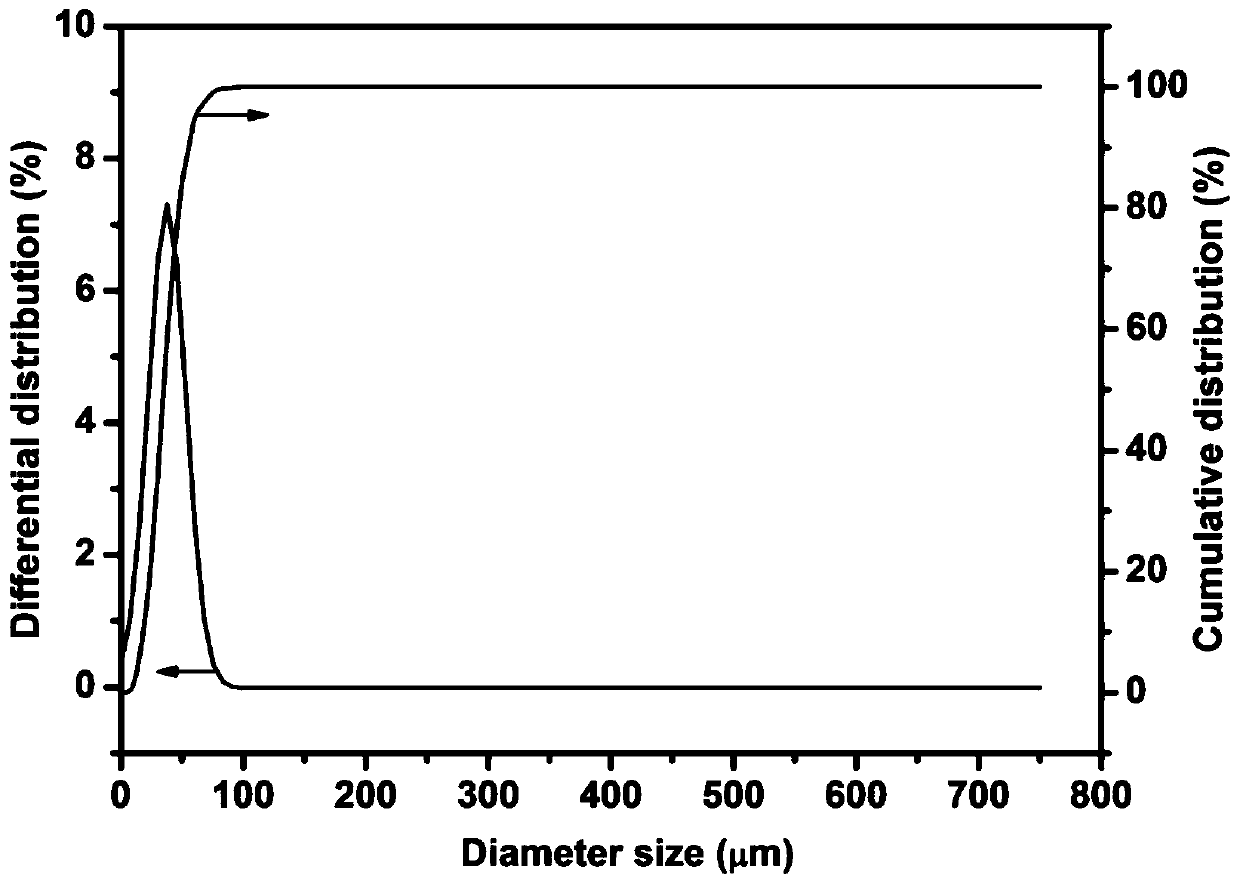

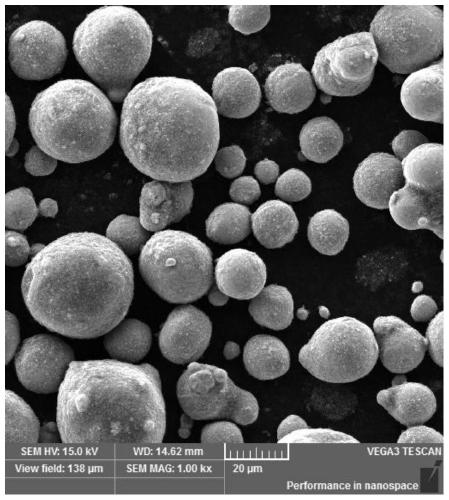

[0038] After ball milling, the particle size of the powder ranges from 15 to 53 μm, of which D50 is 30.35 μm. The particle size distribution of the titanium alloy composite material after ball milling is as follows: image 3 As shown, its SEM morphology is shown in Figure 4 shown.

[0039] The difference betwee...

Embodiment 3

[0042] The difference between the steps of preparing the titanium alloy composite material in this example and Example 1 is:

[0043] The weight percentages of Ti6Al4V, titanium carbide, titanium boride, and titanium silicide are 90%, 5%, 3%, and 2% respectively, the particle size of Ti6Al4V powder is 38μm, and the particle size of titanium carbide, titanium boride, and titanium silicide is 100nm ;

[0044] The diameter of zirconia ceramic balls is 10mm, the mass ratio of zirconia ceramic balls to raw materials is 8:1, the rotation speed of the ball mill is 40rpm up and down, the rotation speed of left and right is 300rpm, and the total time of ball milling is 35h.

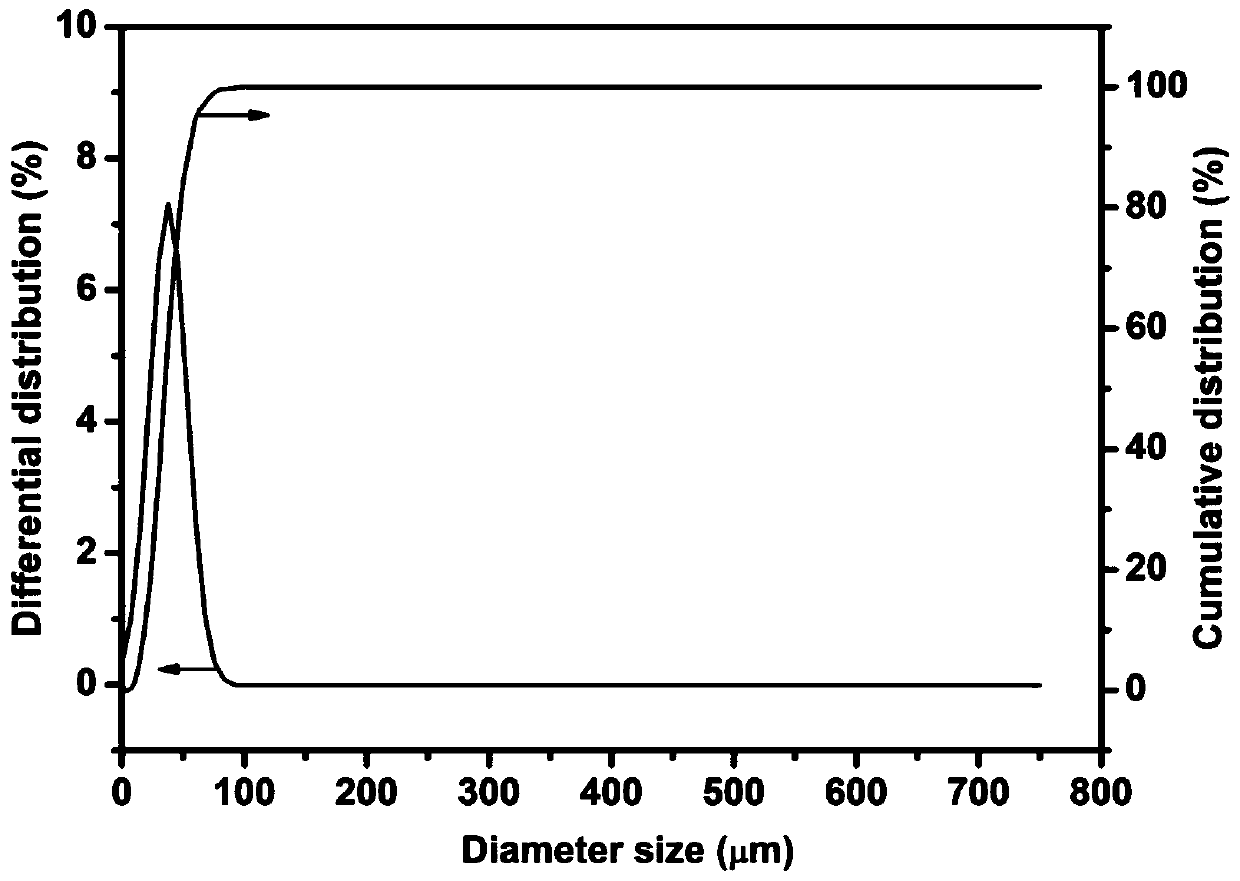

[0045] After ball milling, the particle size of the powder ranges from 15 to 53 μm, of which D50 is 30.35 μm. The particle size distribution of the titanium alloy composite material after ball milling is as follows: Figure 5 As shown, its SEM morphology is shown in Figure 6 shown.

[0046] The difference betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com