PET composite nucleating agent and preparation method thereof

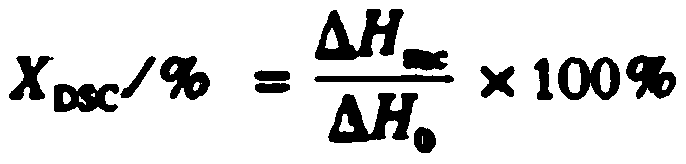

A composite nucleating agent, nucleating agent technology, applied in the field of PET composite nucleating agent and its preparation, can solve the problems of low impact on PET degradation, general nucleation efficiency, and decreased elongation at break, and achieve high elongation at break efficiency, improved physical properties, increased crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

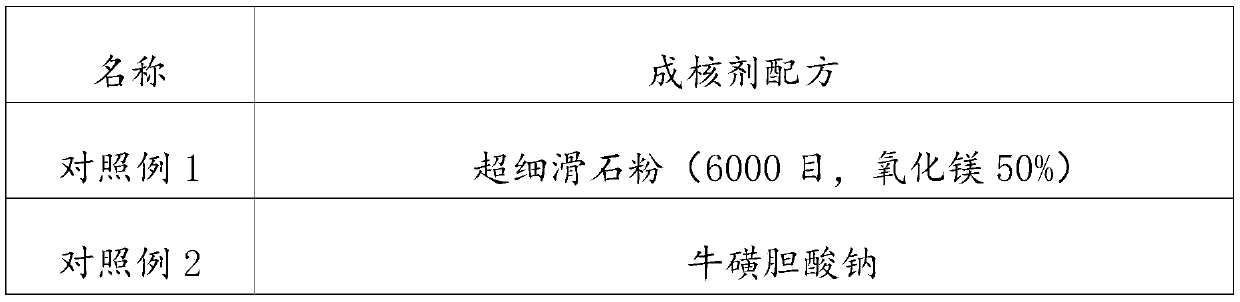

[0045] The present embodiment provides a kind of PET composite nucleating agent, and its raw material comprises by weight parts:

[0046] 20-40 parts of polymer sodium salt;

[0047] 3-10 parts of superfine talcum powder;

[0048] 25-45 parts of polyethylene glycol;

[0049] 20-40 parts of polycarbodiimide;

[0050] Wherein, the total content of all components is 100 parts.

[0051] The high molecular sodium salt is one of sodium taurocholate, sodium cholate, sodium pyrrole carboxylate and C20-C30 heterocyclic sodium carboxylate or a compound of any two.

[0052] Ultrafine talc powder is a compound of magnesia and silicon dioxide or a combination of two, and its mesh number is 5000-6000 mesh; when the ultrafine talc powder is a compound of magnesia and silicon dioxide, the oxidation The mass fraction of magnesium is 40-50%, and the mass fraction of silicon dioxide is 50-60%.

[0053] Polyethylene glycol (PEG) is polyethylene glycol, terephthalic acid modified polyethylene...

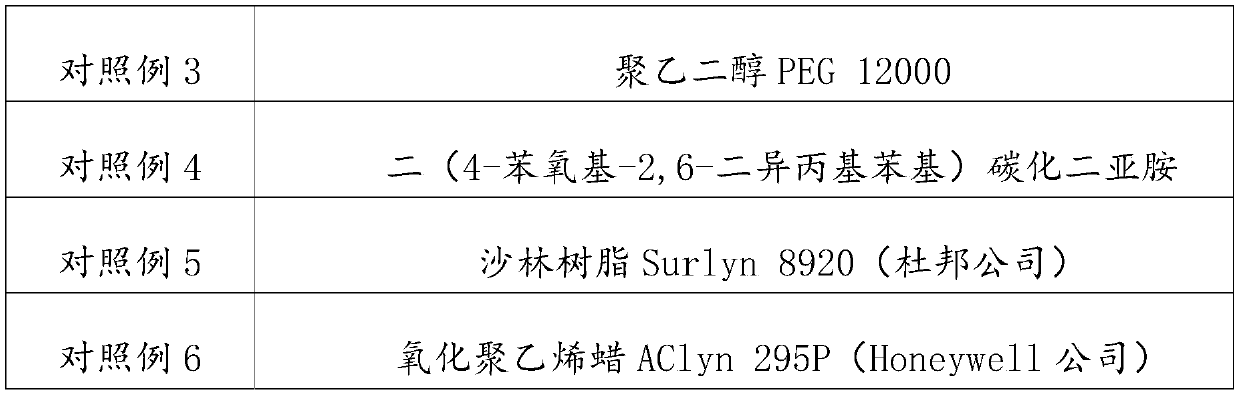

Embodiment 2

[0063] The difference between this embodiment and embodiment 1 is that: the nucleating agent raw material comprises by weight parts:

[0064] 30 parts of sodium taurocholate, 5 parts of talc powder (mesh 6000, magnesium oxide 50%), 35 parts of polyethylene glycol (molecular weight 12000), bis(4-phenoxy-2,6-diisopropyl 30 parts of phenyl) carbodiimide.

Embodiment 3

[0066] The difference between this embodiment and embodiment 1 is that: the nucleating agent raw material comprises by weight parts:

[0067] 30 parts of sodium pyrrole carboxylate, 5 parts of talc powder (mesh 6000, magnesium oxide 50%), 35 parts of polyethylene glycol (molecular weight 12000), bis(4-phenoxy-2,6-diisopropylbenzene base) 30 parts of carbodiimide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com