Anode material used for rechargeable aqueous solution zinc ion battery as well as preparation and application thereof

A technology for zinc-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of lack of negative electrode materials for zinc-ion batteries, achieve good electrochemical cycle stability, simple preparation method, and wide source of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

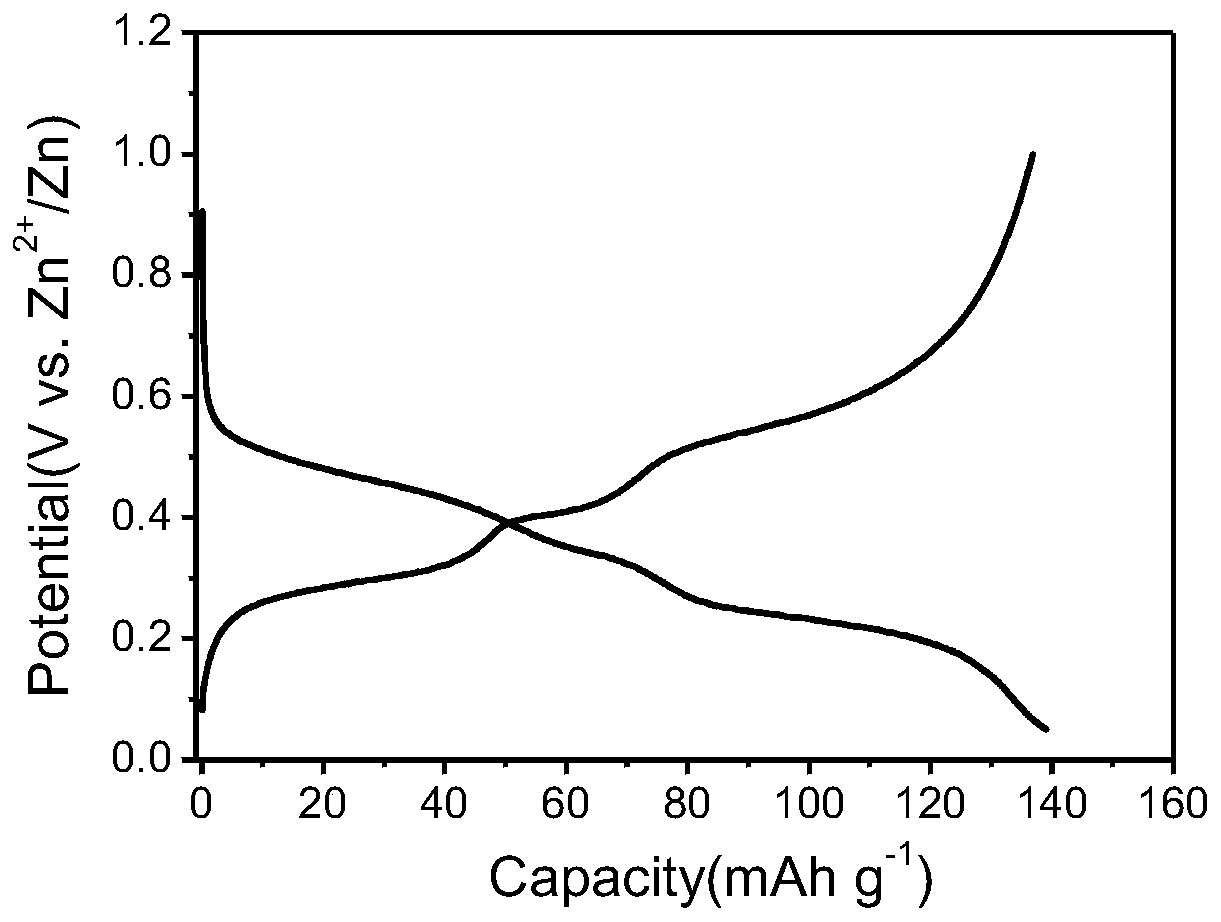

[0027] Weigh 1.0g of titanium disulfide powder, 0.2g of carbon black and 0.2g of PTFE, grind and mix in an agate mortar for 30 minutes, then roll it into a film with a pair of rollers, cut into discs with a diameter of 8mm, and press on Electrodes are made of titanium mesh. The obtained electrode is used as the positive electrode, the zinc sheet is used as the negative electrode, and 8mol / L NaClO 4 +0.2mol / L Zn(CF 3 SO 3 ) 2 The aqueous solution is used as the electrolyte and assembled into a button battery. With different current densities at 0.05-1.2V (vs.Zn 2+ / Zn) is disassembled after the potential interval is circulated once, and washed with deionized water to obtain a kind of sodium ion-modified titanium disulfide electrode material described in Example 1, i.e. Na x TiS 2 , where the x values range from 0.11 to 0.14.

[0028] The value of x can be controlled by adjusting the charge and discharge current density. For example, when the charge and discharge curre...

Embodiment 2

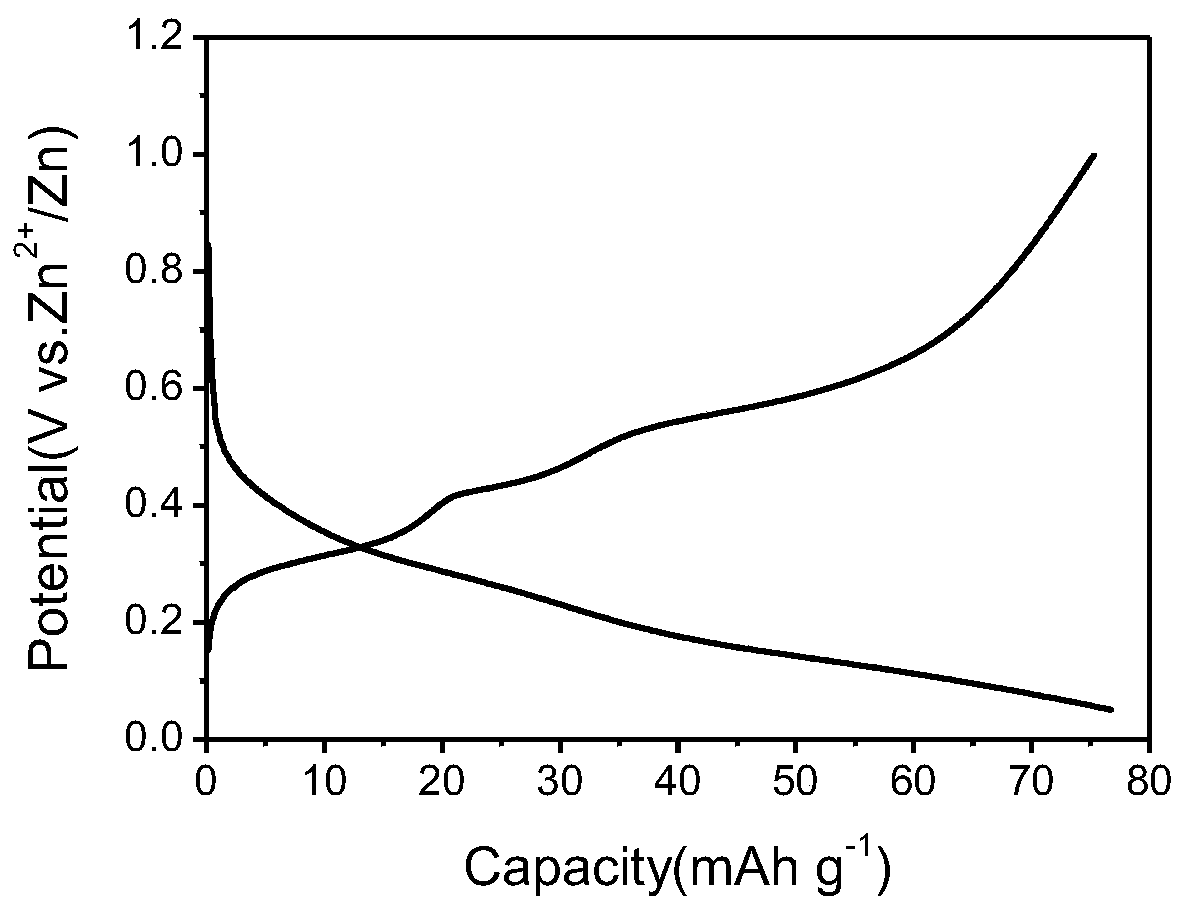

[0031] Weigh 1.0g of titanium disulfide powder, 0.2g of carbon black and 0.2g of PTFE, grind and mix in an agate mortar for 30 minutes, then roll it into a film with a pair of rollers, cut into discs with a diameter of 8mm, and press on Electrodes are made of titanium mesh. The resulting electrode is used as a positive electrode, the zinc sheet is used as a negative electrode, and 8mol / L LiClO 4 +0.2mol / L Zn(CF 3 SO 3 ) 2 The aqueous solution is used as the electrolyte and assembled into a button battery. With different current densities at 0.05-1.2V (vs.Zn 2+ / Zn) after the potential interval cycle once, take it apart, wash with deionized water, obtain a kind of lithium ion-modified titanium disulfide electrode material described in the present embodiment 2, i.e. Li x TiS 2 , where the x values range from 0.05 to 0.13.

[0032] The value of x can be controlled by adjusting the charge and discharge current density. For example, when the charge and discharge current d...

Embodiment 3

[0034] Weigh 1.0g of titanium disulfide powder, 0.2g of carbon black and 0.2g of PTFE, grind and mix in an agate mortar for 30 minutes, then roll it into a film with a pair of rollers, cut into discs with a diameter of 8mm, and press on Electrodes are made of titanium mesh. The obtained electrode is used as positive pole, and zinc sheet is used as negative pole, and 8mol / L KClO 4 +0.2mol / L Zn(CF 3 SO 3 ) 2 The aqueous solution is used as the electrolyte and assembled into a button battery. With different current densities at 0.05-1.2V (vs.Zn 2+ / Zn) is disassembled after the potential interval is circulated once, and washed with deionized water to obtain a titanium disulfide electrode material modified by potassium ions described in Example 3, i.e. K x TiS 2 , where the x values range from 0.12 to 0.2.

[0035] The value of x can be controlled by adjusting the charge and discharge current density. For example, when the charge and discharge current density is 200mAg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com