A new type of bone regeneration-promoting material and preparation method thereof

A new type of nanosheet technology, which is applied in the fields of biomedical materials technology and biomedical engineering, can solve the problems of long degradation time, failure to meet the speed requirements of bone repair in the body, and failure of organic materials to achieve good biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

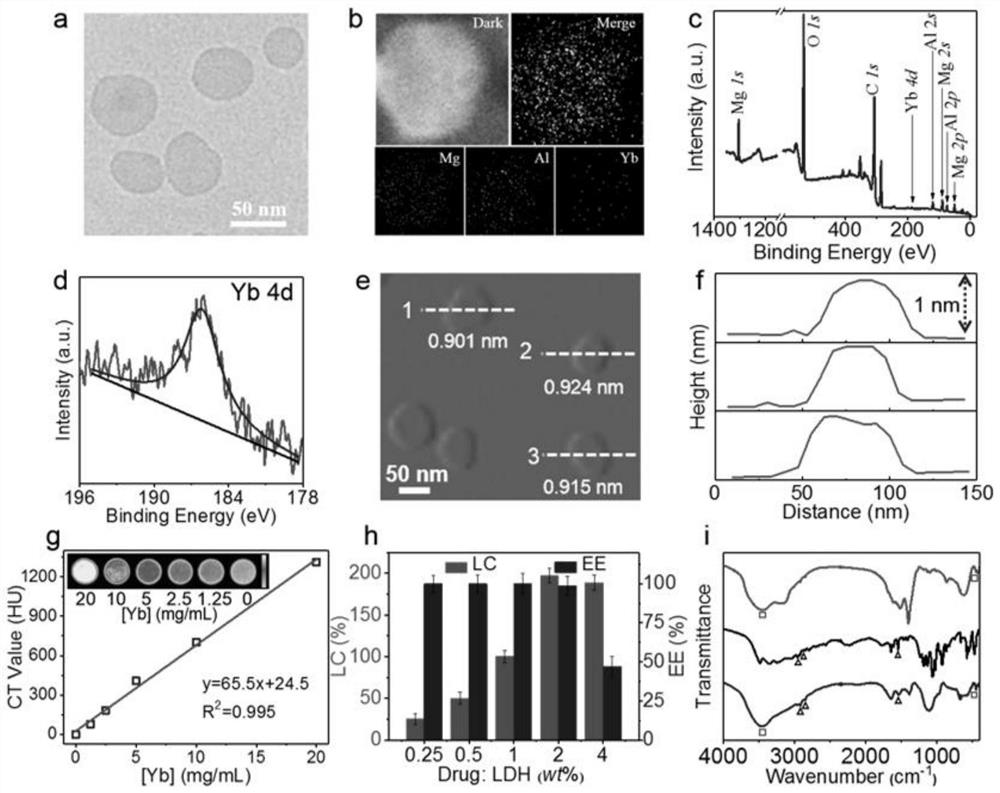

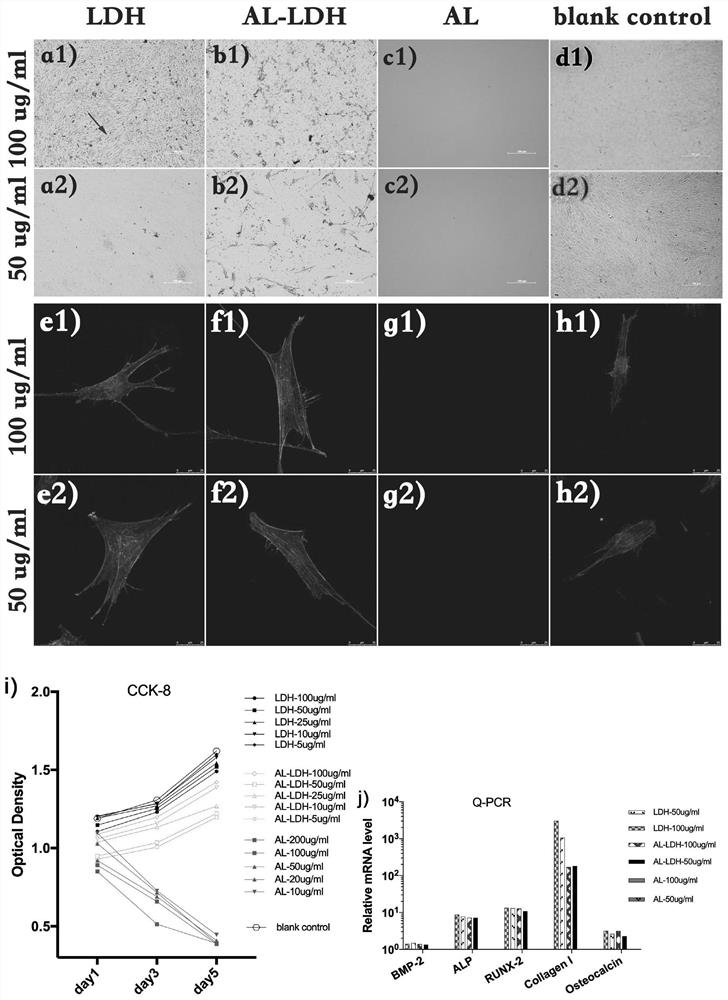

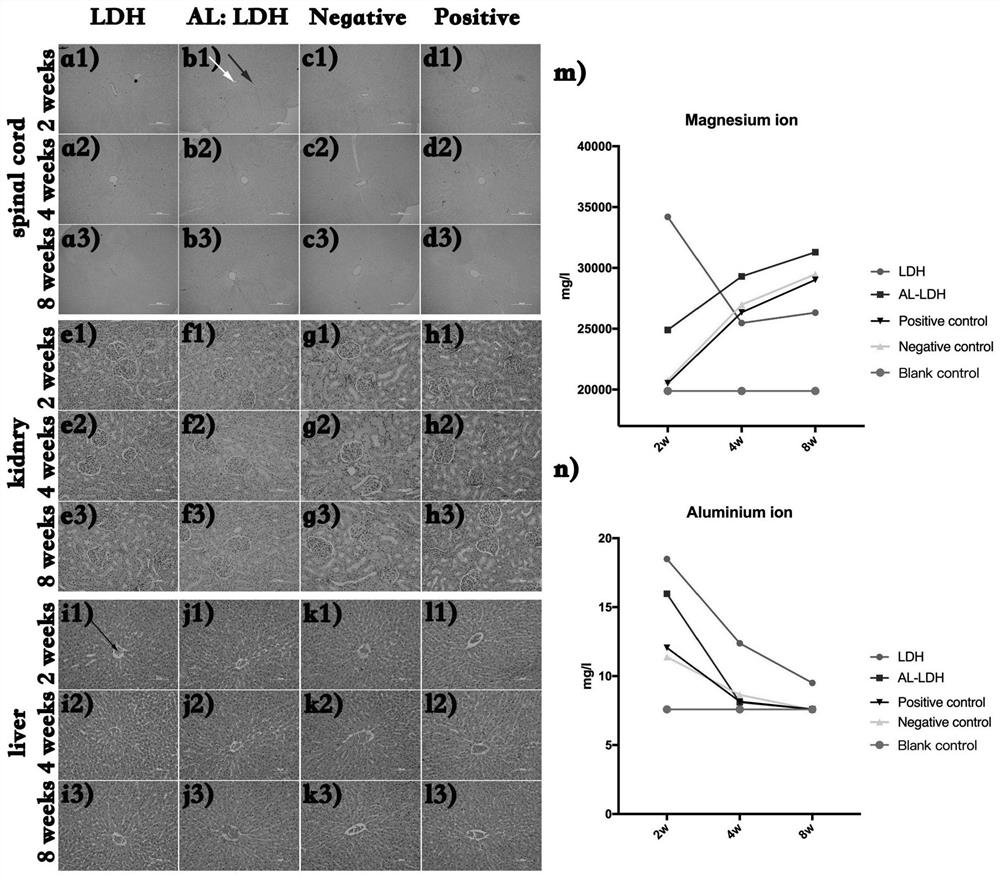

[0052] Embodiment 1 Bone regeneration material 1 preparation

[0053] Mg(NO 3 ) 2 ·6H 2O(Sigma-Aldrich 63084-500G-F), Al(NO 3 ) 3 9H 2 O (Sigma-Aldrich 229415-100G), Yb (NO 3 ) 3 ·5H 2 O (Sigma-Aldrich209147-10G) was weighed according to the molar ratio of 1mmol:1.5mmol:0.4mmol, and dissolved in deionized water. Under the protection of nitrogen, the above three were completely dissolved by mechanical stirring to form a stable and uniform solution of 10mL. Prepare 10mL of 1mM NaOH solution, fully dissolve it for later use; prepare 3% NaNO 3 , and make 10mL mixed solution with formamide according to the ratio of 3:7. The above Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O,Yb(NO 3 ) 3 ·5H 2 O solution and NaOH solution were added dropwise to NaNO 3 In the formamide mixed solution, keep the pH at 9-10, and perform mechanical stirring for 10-15 minutes in an oil bath at 80° C. to 90° C. After the reaction was completed and the solution was cooled, the solution was tak...

Embodiment 2

[0054] Example 2 Preparation of bone regeneration material 2

[0055] Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O,Yb(NO 3 ) 3 ·5H 2 O was weighed according to the molar ratio of 4mmol:0.4mmol:0.5mmol, and dissolved in deionized water. Under the protection of nitrogen, the above three were completely dissolved by mechanical stirring to form a stable and uniform solution of 10mL. Prepare 10mL of 1-1.5mM NaOH solution, fully dissolve it for later use; prepare 3%-5% NaNO 3 , and make 10mL mixed solution with formamide according to the ratio of 3:7. The above Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O,Yb(NO 3 ) 3 ·5H 2 O solution and NaOH solution were added dropwise to NaNO 3 In the formamide mixed solution, keep the pH at 9-10, and perform mechanical stirring for 10-15 minutes in an oil bath at 80° C. to 90° C. After the reaction was completed and the solution was cooled, the solution was taken out and centrifuged, washed three times with a mixture of deionized water...

Embodiment 3

[0056] Embodiment 3 Bone regeneration material 3 preparation

[0057] Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O,Yb(NO 3 ) 3 ·5H 2 O was weighed according to the molar ratio of 2mmol:0.8mmol:0.2mmol, and dissolved in deionized water. Under the protection of nitrogen, the above three were completely dissolved by mechanical stirring to form a stable and uniform solution of 10mL. Prepare 10mL of 1-1.5mM NaOH solution, fully dissolve it for later use; prepare 3%-5% NaNO 3 , and make 10mL mixed solution with formamide according to the ratio of 3:7. The above Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O,Yb(NO 3 ) 3 ·5H 2 O solution and NaOH solution were added dropwise to NaNO 3 In the formamide mixed solution, keep the pH at 9-10, and perform mechanical stirring for 10-15 minutes in an oil bath at 80° C. to 90° C. After the reaction was completed and the solution was cooled, the solution was taken out and centrifuged, washed three times with a mixture of deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com