An environmentally friendly process for purifying tail gas from potassium sulfate production

A potassium sulfate, tail gas technology, applied in chlorine/hydrogen chloride, chemical instruments and methods, chlorine/hydrogen chloride purification, etc., can solve the problems of increasing processing cost, poor quality of hydrochloric acid, poor supporting processing equipment, etc. High rate, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

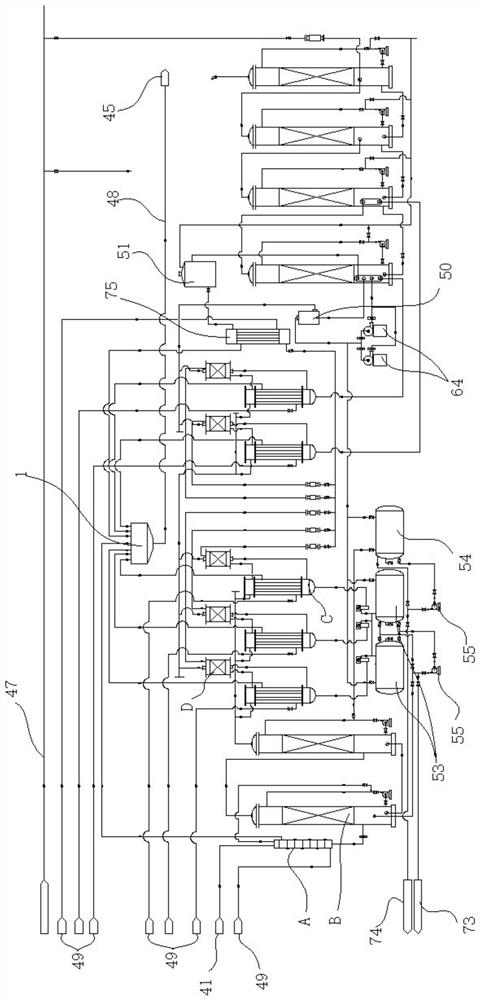

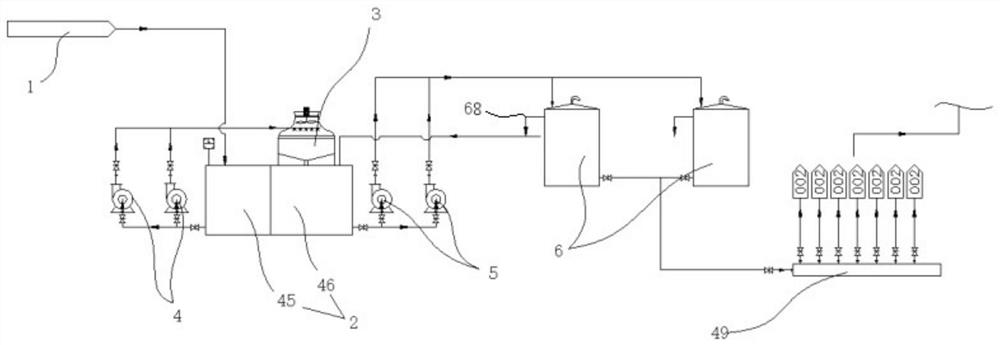

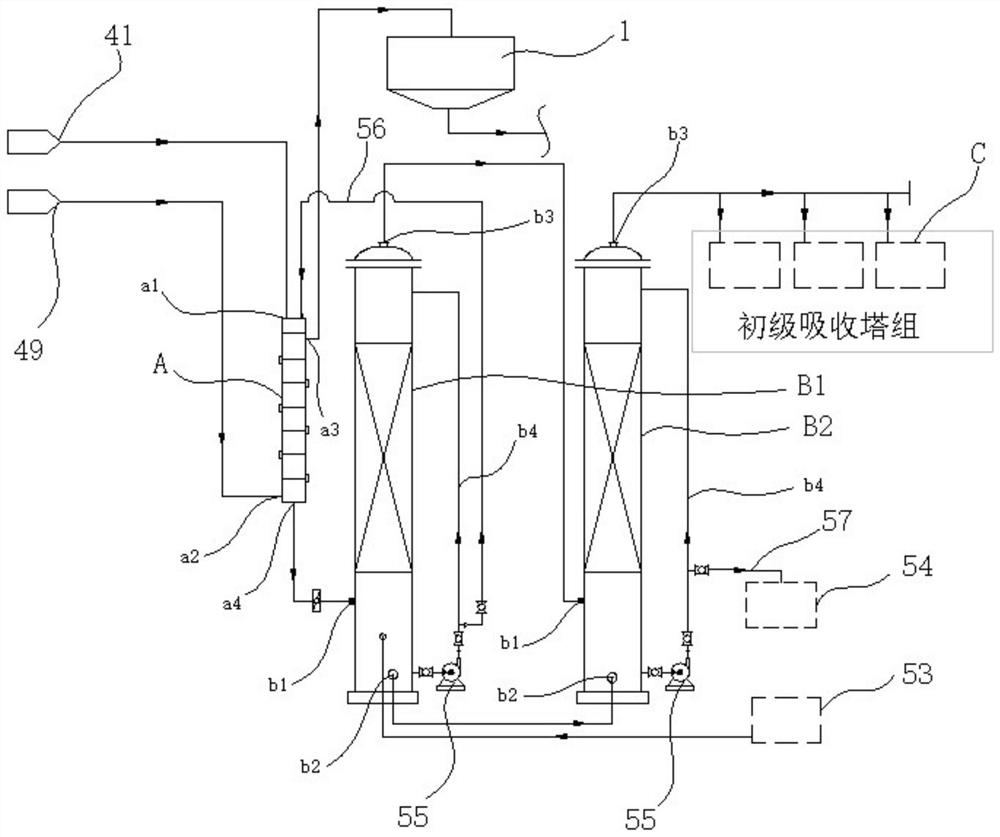

[0047] As shown in the figure, an environmentally friendly process for purifying the tail gas produced by potassium sulfate is characterized in that the environmentally friendly process uses tail gas treatment equipment for tail gas treatment, and the process flow of the environmentally friendly process includes tail gas cooling, B acid production, A acid production, dilute Hydrochloric acid production and cooling water circulation.

[0048] The above-mentioned environmental protection process for purifying potassium sulfate to produce tail gas, wherein, the tail gas treatment equipment includes tail gas conveying pipeline, graphite cooler, primary scrubber group, secondary scrubber group, primary absorption tower group, secondary absorption tower group , gas-liquid separator, acid bucket, hydrochloric acid intermediate tank and water circulation cooling assembly, the primary scrubber group is composed of 2 sulfuric acid gas scrubbers in series, and the secondary scrubber group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com