Preparation method of morphologically controllable cuprous oxide crystals

A cuprous oxide and morphology technology, applied in copper oxide/copper hydroxide and other directions, can solve the problems of increasing the difficulty of preparation and product cleaning, reducing the activity of cuprous oxide, and difficult to mass-produce, and achieving uniform morphology. , The effect of short response time and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

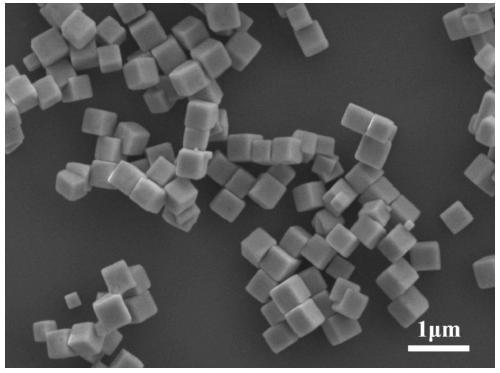

[0027] Example 1: Preparation of cubic cuprous oxide crystals by selection of chloride ions

[0028] (1) Set the water bath reaction temperature to 55°C, add dropwise 10 mL of 2 mol / L NaOH solution to 100 mL of 0.01 mol / L CuCl 2 In the aqueous solution, stir the reaction for 30min.

[0029] (2) 10 mL of 0.6 mol / L reducing agent ascorbic acid was added dropwise to the mixed solution, reacted in a water bath for 1 h, the product was centrifuged, washed and dried to obtain cuprous oxide crystals with a cubic shape.

Embodiment 2

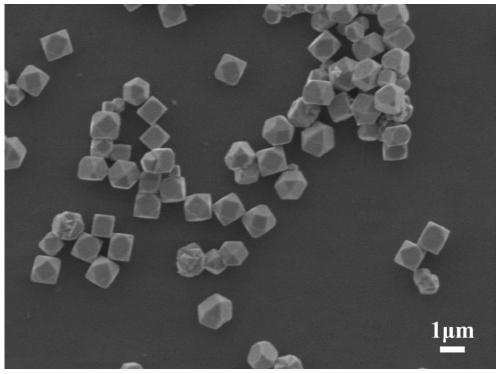

[0030] Example 2: Preparation of cubo-octahedral cuprous oxide crystals by selection of bromide ions

[0031] (1) Set the water bath reaction temperature to 55°C, add dropwise 10 mL of 2 mol / L NaOH solution to 100 mL of 0.01 mol / L CuBr 2 In the aqueous solution, stir the reaction for 30min.

[0032] (2) 10 mL of 0.6 mol / L reducing agent ascorbic acid was added dropwise to the mixed solution, reacted in a water bath for 1 h, the product was centrifuged, washed, and dried to obtain cuprous oxide crystals with cuboctahedral morphology.

Embodiment 3

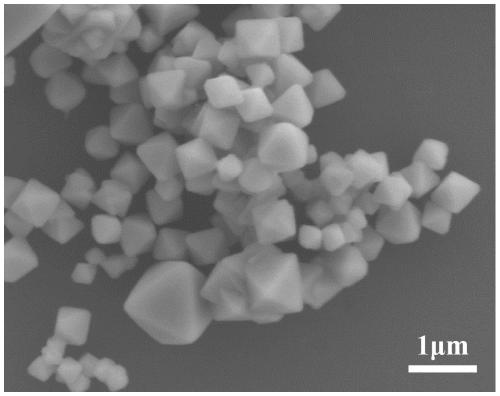

[0033] Example 3: Preparation of octahedral cuprous oxide crystals by selection of iodide ions

[0034] (1) Set the water bath reaction temperature to 55°C, add 10 mL of 2 mol / L NaOH solution dropwise into 100 mL of 0.01 mol / L CuI aqueous solution, and stir for 30 min.

[0035] (2) 10 mL of 0.6 mol / L reducing agent ascorbic acid was added dropwise to the mixed solution, reacted in a water bath for 1 h, and the product was centrifuged, washed and dried to obtain cuprous oxide crystals with octahedral morphology.

[0036] Figure 1-3 They are the scanning electron microscope images of the cuprous oxide crystals prepared in Examples 1-3, respectively. By adjusting the type of halide anion in the reaction system, three cuprous oxide crystals with different shapes of cube, cubo-octahedron and octahedron were prepared. And the crystal structure is complete and the morphology is uniform. Figure 4 Then it is the XRD phase analysis figure of the cuprous oxide crystal prepared in e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com