Active silicone oil and low-pollution heat-conducting silicone grease composition

A technology of active silicone oil and thermally conductive silicone grease, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of oil separation, migration, hardening, and cracking of thermally conductive silicone grease, and achieve the effect of solving cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

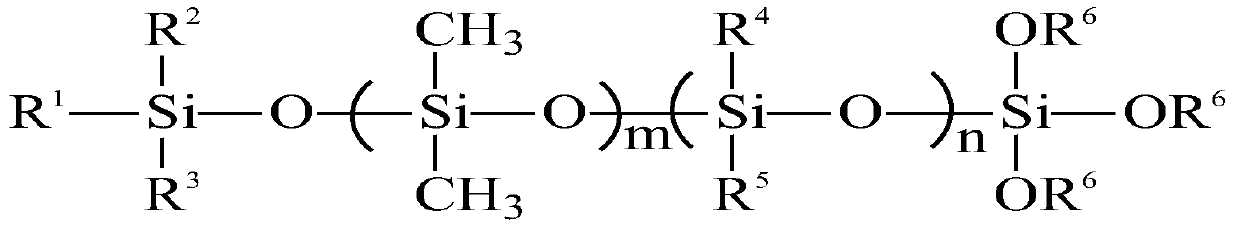

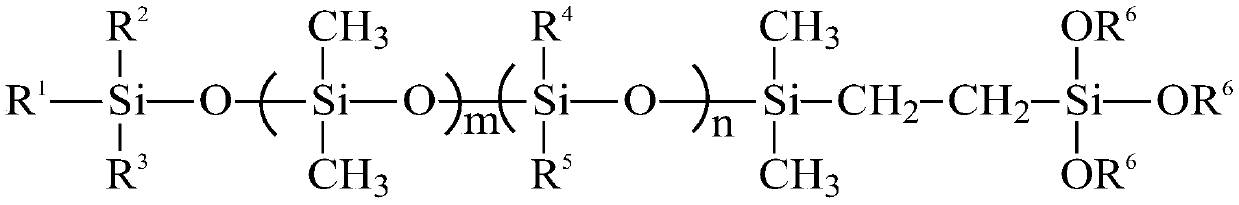

Method used

Image

Examples

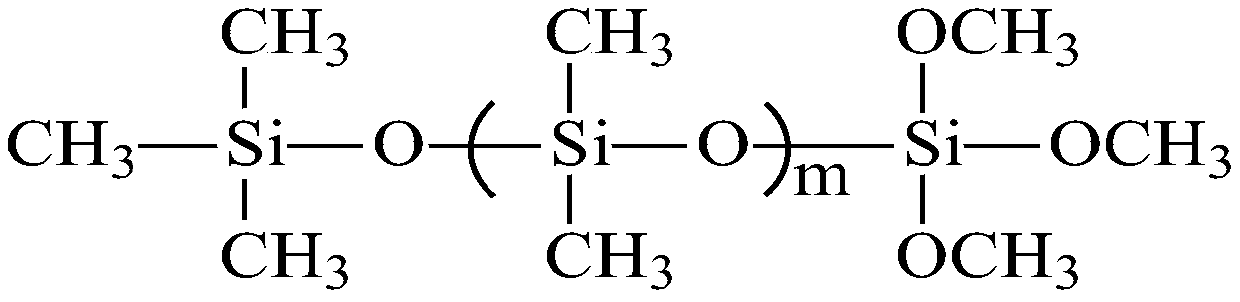

Embodiment 1

[0056] Use 100g of synthetic A-structure silicone oil (m=28, viscosity 45mPa.s, silicone low-molecular ring body ΣD3~D10=80ppm), 300g zinc oxide (median particle size 0.5 microns), mix well, and vacuum defoam , Obtain example 1# thermal conductive silicone grease.

Embodiment 2

[0058] Use 70g of silicone oil with structure C synthesized (m=28, viscosity 45mPa.s, organic silicon low-molecular ring body ΣD3~D10=80ppm), 30g of bis(terminal trimethylsilane) bis(terminal trimethylsilane) to control ΣD3~D10 at 110ppm Methyl silicone oil (viscosity 500mPa.s), 300g zinc oxide (median particle size 0.5 micron), mixed evenly, vacuum defoaming, to obtain example 2 thermal conductive silicone grease.

Embodiment 3

[0060] The structure that is synthesized with 100g is the silicone oil (m=100, viscosity 300mPa.s, organosilicon low molecular ring body ΣD3~D10=120ppm) of F, 500g zinc oxide (median particle size 0.5 micron), 800g spherical aluminum oxide ( Median particle diameter 5 micrometers), mixed uniformly, vacuum defoaming, obtained Example 3 thermal conductive silicone grease.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com