Preparation method of pigment yellow 150

A technology for pigment yellow and pigment slurry, which is applied in the field of preparation of pigment yellow 150, can solve the problems affecting the transparency, fluidity and color strength of products, unstable product quality performance, poor quality repeatability, etc., so as to improve application performance, dispersion Excellent stability, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

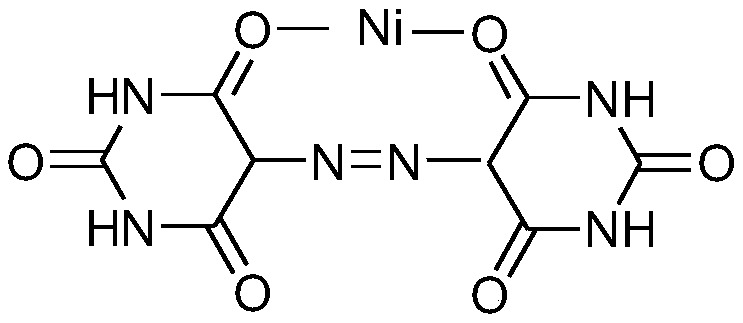

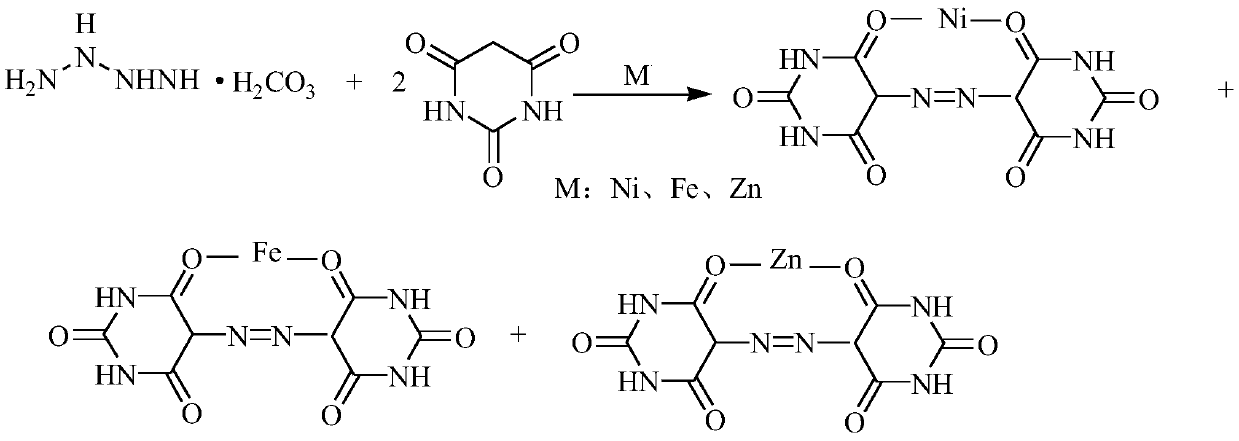

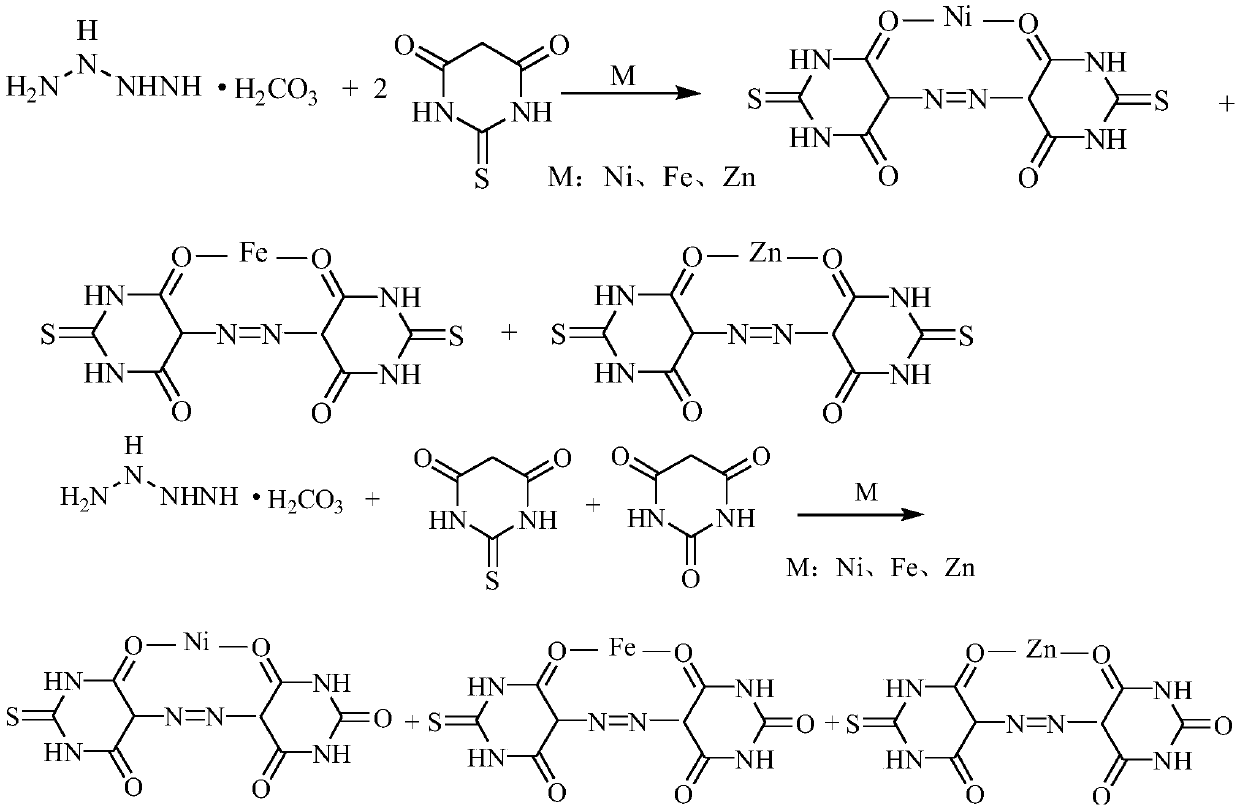

Image

Examples

Embodiment 1

[0044] One, the preparation of azobarbituric acid sodium salt

[0045] (1) Preparation of diazo solution

[0046] Add 85ml of water to a 500mL beaker, add 9.23g of aminoguanidine bicarbonate, stir for 30min, and slowly add 19.6g of hydrochloric acid (30%) under stirring for 10min. Add ice and cool down to 0°C. After adding 4.96g of sodium nitrite (96%) into 12.5ml of water to dissolve clearly, it was added to the above reaction and stirred for 20min.

[0047] (2) Coupling reaction

[0048] Add 17.52g of barbituric acid and 0.2g of thiobarbituric acid into the diazonium solution in 10 minutes, and stir for 30 minutes to obtain a pigment slurry.

[0049] (3) post-processing

[0050] Raise the temperature of the pigment slurry to 50°C and keep it warm for 1.5h. 2.05 g of sodium acetate was added, and the pH was adjusted to 4.6 with 50% sodium hydroxide solution. The reactant was stirred at 50° C. for 1 hour, then heated to 100° C., and kept for 4 hours. Cool the reactant to...

Embodiment 2

[0054] One, the preparation of azobarbituric acid sodium salt

[0055] (1) Preparation of diazo solution

[0056] Add 85ml of water to a 500mL beaker, add 9.23g of aminoguanidine bicarbonate, stir for 30min, and slowly add 19.6g of hydrochloric acid (30%) under stirring for 10min. Add ice and cool down to 0°C. After adding 4.96g of sodium nitrite (96%) into 12.5ml of water to dissolve clearly, it was added to the above reaction and stirred for 20min.

[0057] (2) Coupling reaction

[0058] Add 17.35g of barbituric acid and 0.4g of thiobarbituric acid into the diazonium solution in 10 minutes, and stir for 30 minutes to obtain a pigment slurry.

[0059] (3) post-processing

[0060] Raise the temperature of the pigment slurry to 50°C and keep it warm for 1.5h. 2.05 g of sodium acetate was added, and the pH was adjusted to 4.6 with 50% sodium hydroxide solution. The reactant was stirred at 50° C. for 1 hour, then heated to 100° C., and kept for 4 hours. Cool the reactant to 7...

Embodiment 3

[0064] One, the preparation of azobarbituric acid sodium salt

[0065] (1) Preparation of diazo solution

[0066] Add 85ml of water to a 500mL beaker, add 9.23g of aminoguanidine bicarbonate, stir for 30min, and slowly add 19.6g of hydrochloric acid (30%) under stirring for 10min. Add ice and cool down to 0°C. After adding 4.96g of sodium nitrite (96%) into 12.5ml of water to dissolve clearly, it was added to the above reaction and stirred for 20min.

[0067] (2) Coupling reaction

[0068] Add 17.17g of barbituric acid and 0.6g of thiobarbituric acid into the diazonium solution in 10 minutes. After the addition is complete, stir for 30 minutes to obtain a pigment slurry.

[0069] (3) post-processing

[0070] Raise the temperature of the pigment slurry to 50°C and keep it warm for 1.5h. 2.05 g of sodium acetate was added, and the pH was adjusted to 4.6 with 50% sodium hydroxide solution. The reactant was stirred at 50° C. for 1 hour, then heated to 100° C., and kept for 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com