Preparation method of pyrene ketone type solvent dye

A technology of solvent dyes and pyrene, which is applied in the field of preparation of pyrene-based solvent dyes, can solve the problems of product separation, organic solvent recovery difficulties, incomplete DMF recovery, and high cost of wastewater treatment, and achieve complete solvent recovery, good quality, and applicable broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention provides a method for preparing a pyrenone solvent dye, the pyrene solvent dye includes Solvent Orange 60, Solvent Red 135 or Solvent Red 179, and the preparation method includes the following steps:

[0024] 1,8-diaminonaphthalene, acid anhydride and non-water-soluble organic solvent are mixed and then subjected to condensation reaction to obtain pyrenone solvent dye;

[0025] The acid anhydride includes phthalic anhydride, tetrachlorophthalic anhydride or 1,8-naphthalene anhydride.

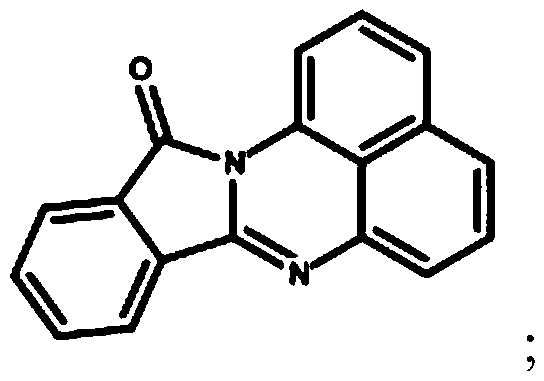

[0026] In the present invention, the pyrenone solvent dye prepared by using phthalic anhydride as a raw material is Solvent Orange 60, and the structural formula is as follows:

[0027]

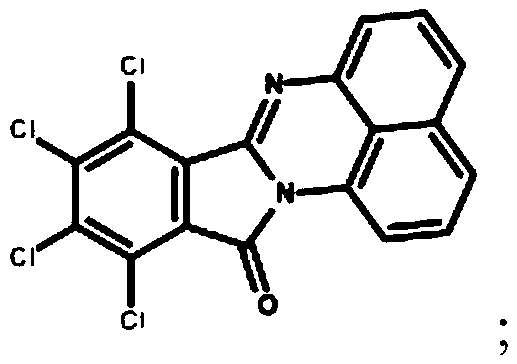

[0028] The pyrenone solvent dye prepared with tetrachlorophthalic anhydride as a raw material is Solvent Red 135, and the structural formula is as follows:

[0029]

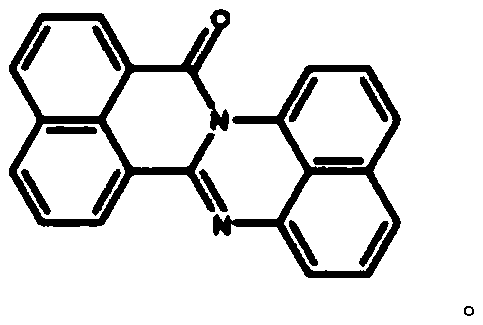

[0030] The pyrenone solvent dye prepared with 1,8-naphthalene anhydride as a raw material is Solvent Red 179, and the structur...

Embodiment 1

[0054] In a three-necked flask with stirring and reflux condenser, add 15.82g (0.1mol) of 1,8-diaminonaphthalene, 14.81g (0.1mol) of phthalic anhydride, 405.44g of toluene and 20.27g of acetic acid, turn on stirring, and heat to reflux State heat preservation reaction for 6h to obtain condensation product system;

[0055] Steam is introduced into the condensation product system for distillation, the distillate obtained by distillation is allowed to stand for stratification, and toluene is separated and recovered (recovery rate 98%); the residue obtained by distillation is suction filtered while hot, and the filter cake is heated at 60°C After washing with water until the filtrate is clear and the pH value is in the range of 6-8, 26.27 g of Solvent Orange 60 solid is obtained after drying (yield 97.2%).

[0056] Comparing the solvent orange 60 solid prepared in this example with the solvent orange 60 standard product, the ΔE is 0.35, the ΔC is 0.19, the strength is 100.72%, and the ...

Embodiment 2

[0058] In a three-necked flask with stirring and reflux condenser, add 15.82g (0.1mol) of 1,8-diaminonaphthalene, 14.81g (0.1mol) of phthalic anhydride, 405.44g of toluene and 40.54g of acetic acid, turn on stirring, and heat to reflux State insulation reaction for 3h to obtain condensation product system;

[0059] Steam is introduced into the condensation product system for distillation, the distillate obtained by distillation is allowed to stand for stratification, and toluene is separated and recovered (recovery rate of 97%); the residue obtained by distillation is suction filtered while hot, and the filter cake is heated at 80°C After washing with water until the filtrate is clear and the pH value is in the range of 6-8, 25.49g of Solvent Orange 60 is obtained by drying (94.3% yield).

[0060] Comparing the solvent orange 60 solid prepared in this embodiment with the solvent orange 60 standard product, the ΔE is 0.20, the ΔC is -0.09, the strength is 99.96%, and the product qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com