Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of increased preparation cost, time-consuming consumables, extra energy consumption, etc., and achieves the effect of eliminating Schottky barrier, saving process cost, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

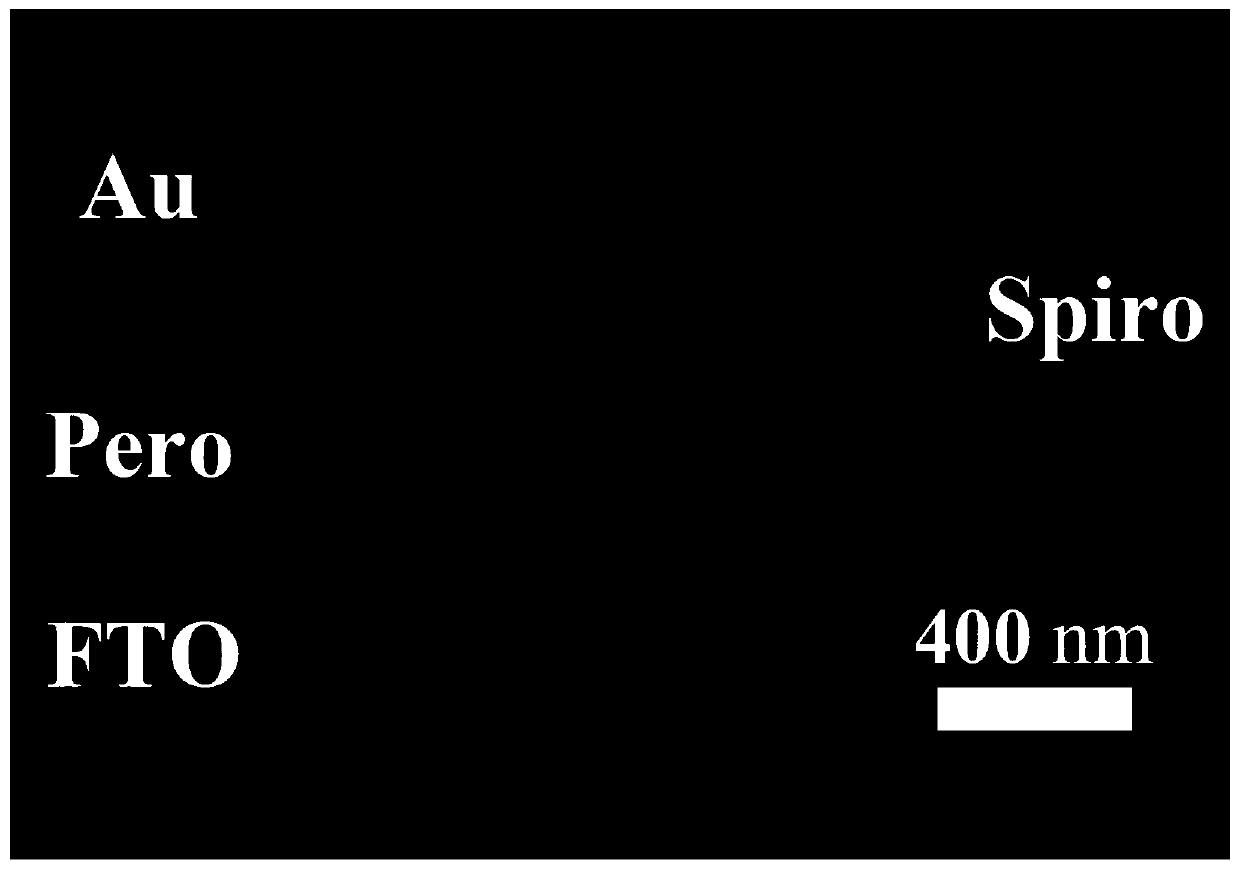

[0036] Step 1. Perform plasma treatment on FTO, the specific steps are:

[0037] Step 1.1. Place the FTO substrate material in acetone, absolute ethanol and deionized water for 20 minutes, and then dry it with a nitrogen gun for later use;

[0038] Step 1.2. Place the FTO substrate material cleaned in step 1.1 on the metal lower plate in the plasma chamber, the distance between the metal plates is 34mm, the upper plate is connected to 27MHz RF power supply, and the lower plate is connected to 13.56MHz RF power supply;

[0039] Step 1.3. Vacuum the plasma chamber to a vacuum of 10 -3 Pa, then feed oxygen with a purity of 99.999%, and control the oxygen flow rate so that the working pressure in the chamber is 15Pa;

[0040] Step 1.4. Set the discharge power of the upper plate to 180W, the discharge power of the lower plate to 44W, discharge the upper and lower plates at the same time, and perform plasma treatment on the FTO substrate for 15 minutes, so that the F element on the ...

Embodiment 2

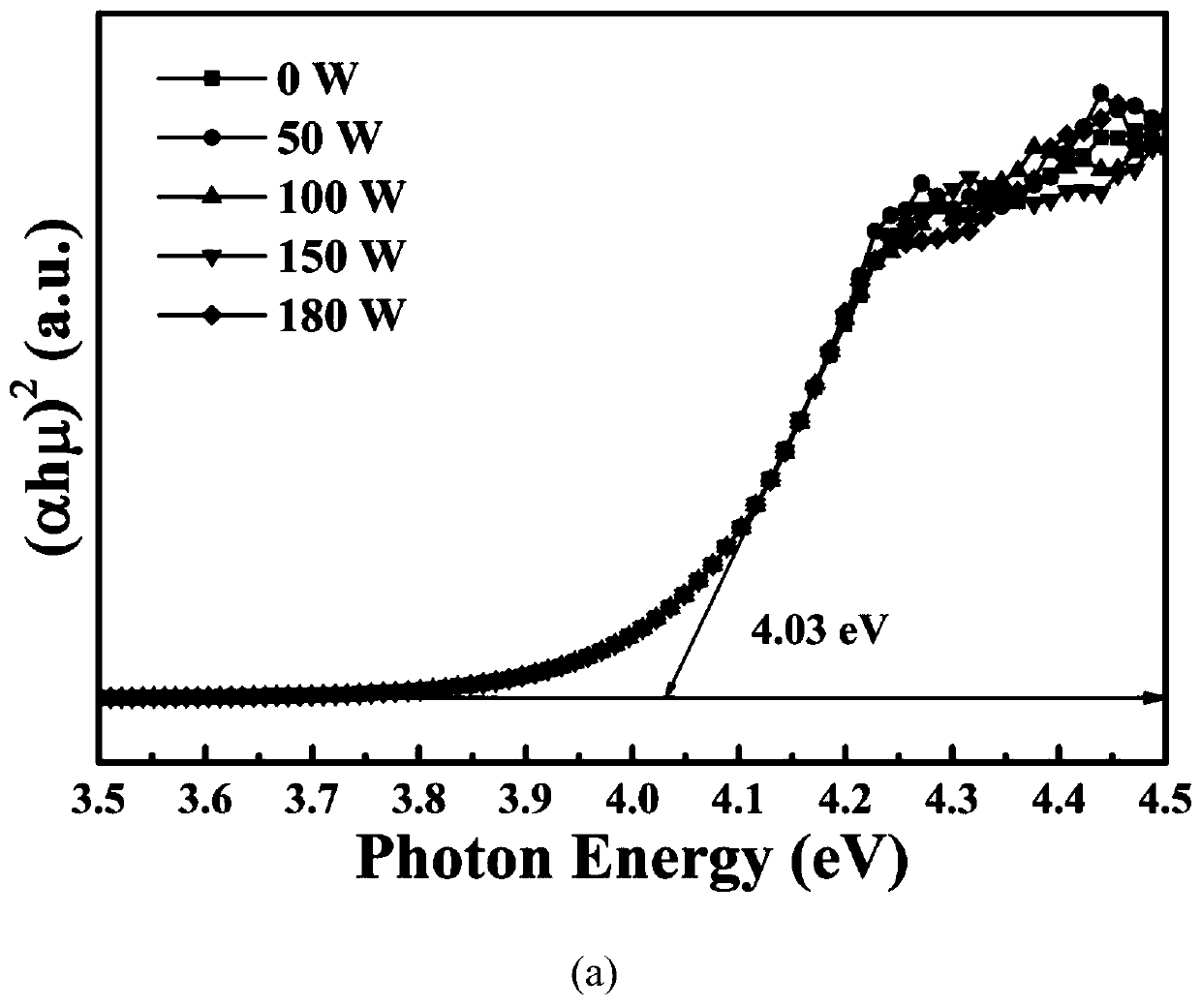

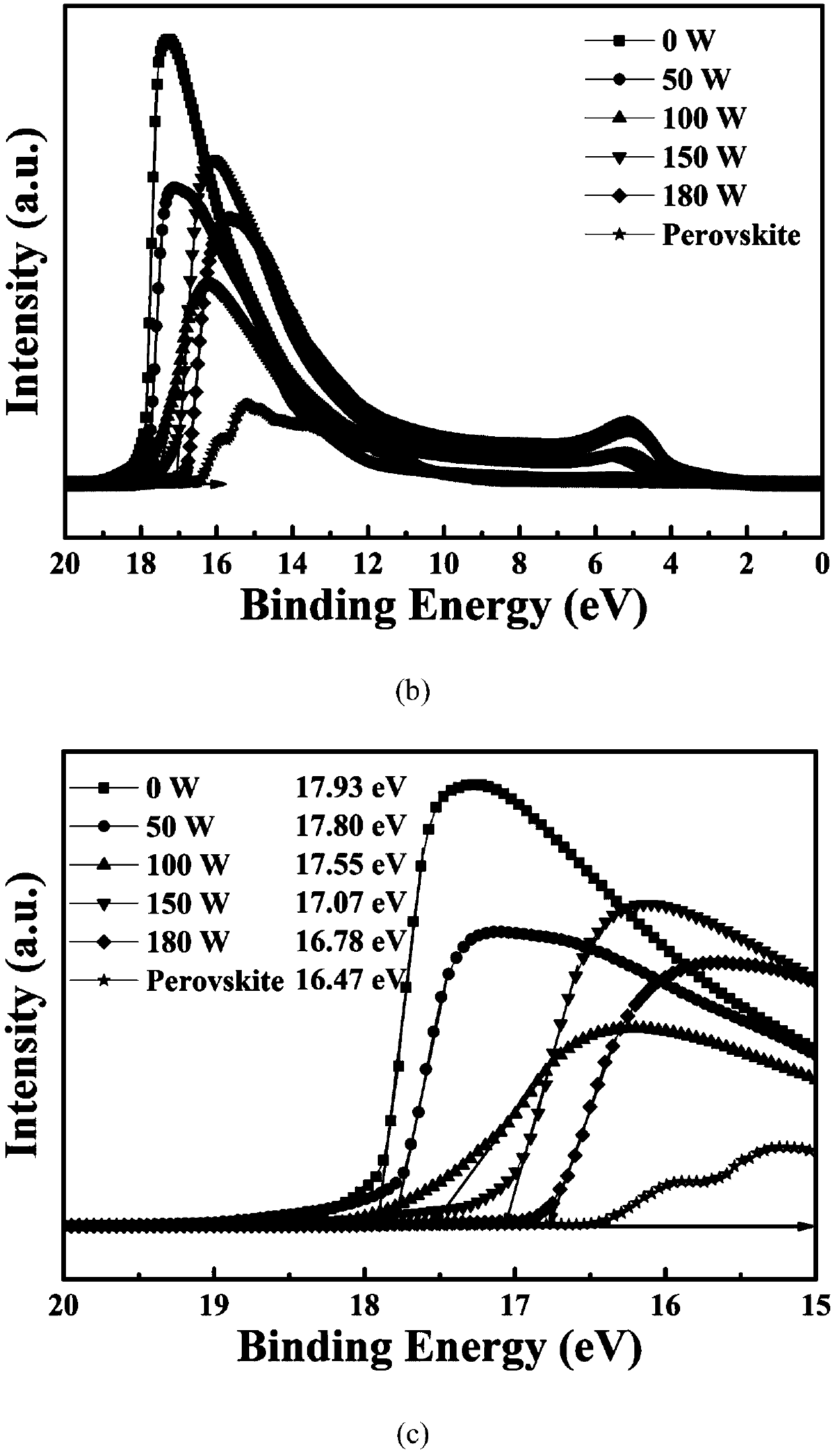

[0046] The perovskite battery was prepared according to the steps of Example 1, only the discharge power of the upper plate in Step 1 was adjusted to 50W, 100W or 150W, and other steps were kept unchanged. The ultraviolet photoelectron spectrum of the perovskite solar cell prepared in this embodiment is as follows figure 2 As shown, the device J-V performance graph is shown in image 3 shown.

Embodiment 3

[0048] The perovskite battery was prepared according to the steps in Example 1, only the plasma treatment time in step 1.4 was adjusted to 30 min, and the other steps remained unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com