A kind of single crystal high-nickel ternary positive electrode material and preparation method thereof

A positive electrode material and high-nickel technology, which is applied in the field of single crystal high-nickel ternary positive electrode materials and its preparation, can solve the problems of high discharge capacity decay rate, low thermal runaway temperature, and low charge and discharge capacity, and achieve discharge capacity decay The effect of small rate, high thermal runaway temperature, and high charge and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

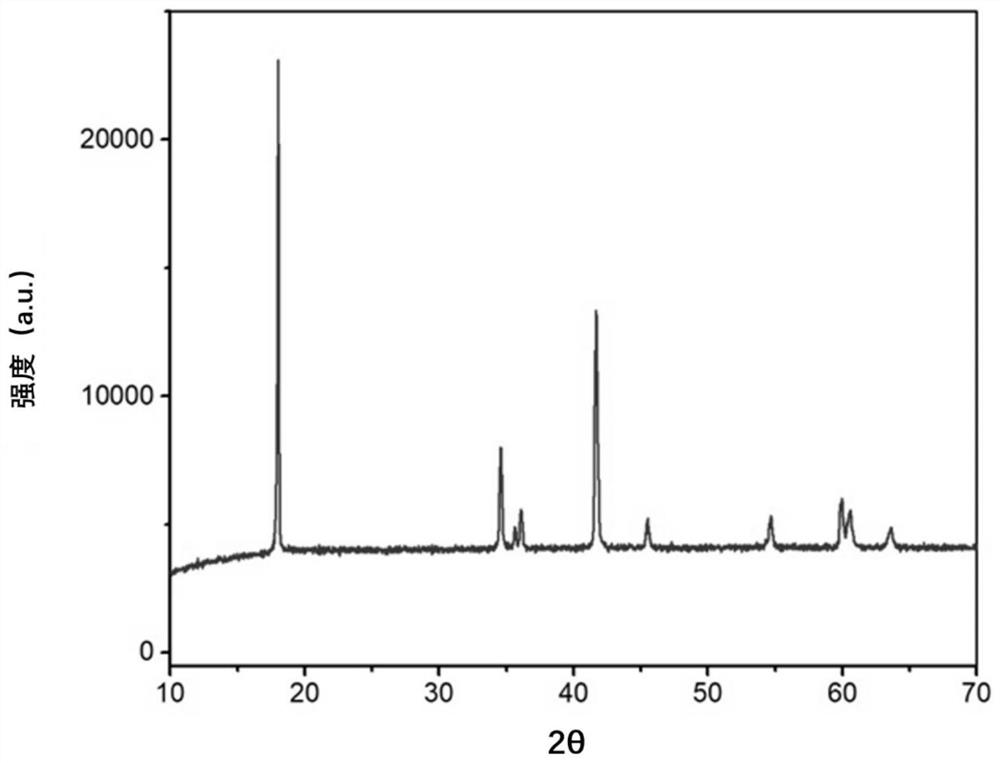

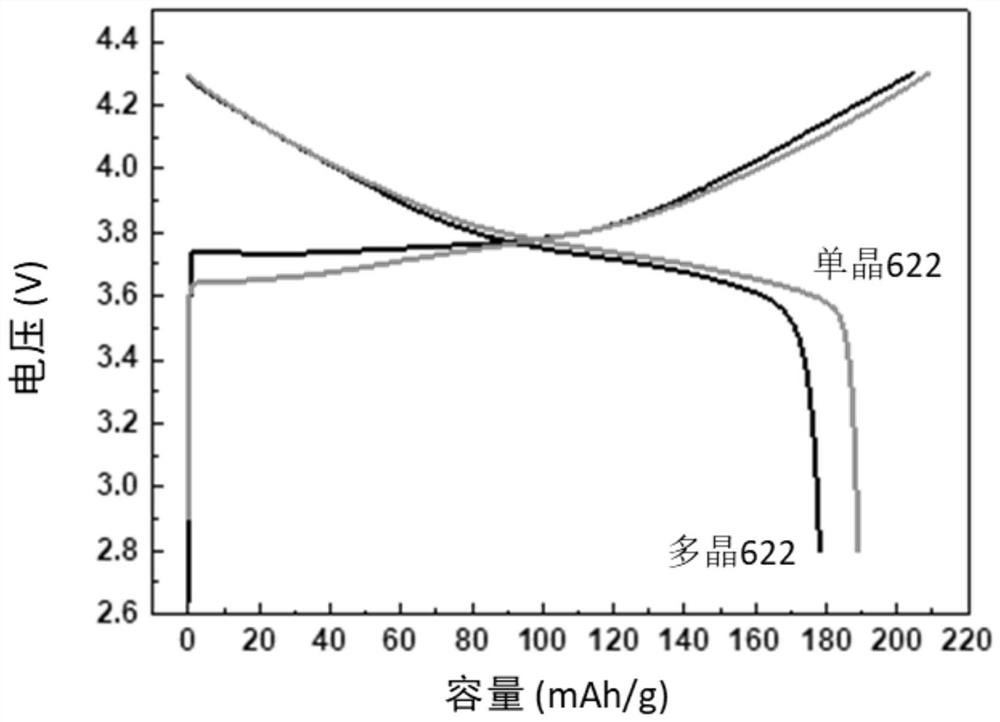

[0052] The precursor Ni purchased from the market 0.6 co 0.2 mn 0.2 (OH) 2 (purchased from Jiangsu Haian Zhichuan New Material Company, 9.2g, 0.1mol), LiOH (purchased from Acros, 2.874g, 0.12mol), Na 2 SO 4 (purchased from Greagent, 7.102g, 0.05mol) mixed evenly, put into a corundum crucible, heated to 950°C at a heating rate of 10°C / min, kept for 15 hours, and naturally cooled to room temperature (approximately 25°C-35°C °C), the resulting mixture was washed three times with deionized water, dried in vacuum at 120 °C for 3 hours, then heated to 750 °C at a heating rate of 10 °C / min, kept for 6 hours, and naturally cooled to room temperature to obtain product 1 , that is, single crystal 622 ternary material.

[0053] Electrochemical test: the single crystal 622 ternary material obtained above was mixed with conductive carbon and PVDF (polyvinylidene fluoride) binder in a ratio of 90:5:5 (mass ratio) in NMP (N-methylpyrrolidone ) and coated on an aluminum foil to obtain a...

Embodiment 2

[0056] Precursor Ni from the market 0.8 co 0.1 mn 0.1 (OH) 2(9.236g, 0.1mol), LiOH (3.114g, 0.13mol), CsCl (8.418g, 0.05mol) (manufacturer of source of material is the same as Example 1) mix uniformly, put into corundum crucible, with 10 ℃ / min heating rate, heated to 780°C, kept for 15 hours, naturally cooled to room temperature, the mixture was washed three times with deionized water, dried in vacuum at 120°C for 3 hours, then put into a crucible, heated to 750°C at a heating rate of 10°C / min ℃, kept for 6 hours, and naturally cooled to room temperature to obtain product 2, which is the single crystal 811 ternary material. The electrochemical test method is the same as in Example 1.

[0057] Figure 8 It is a scanning electron micrograph of product 2 (single crystal 811 ternary material). Figure 9 It is the first electrochemical charge and discharge curve of product 2 (single crystal 811 ternary material). The figure shows that the discharge capacity of product 2 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com