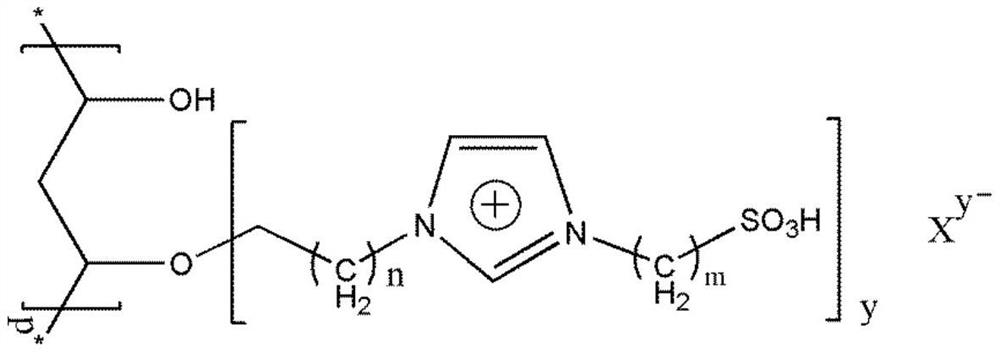

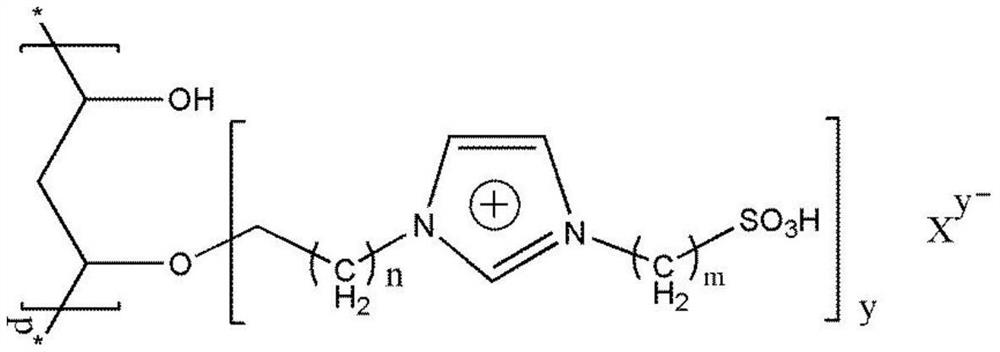

PVA catalytic composite membrane functionalized with ionic liquid and preparation method thereof

A technology of ionic liquid and composite membrane, applied in the field of materials science, can solve the problems of large amount of ionic liquid, easy to be corroded, difficult to recycle, etc., and achieve the effects of low price, high conversion rate, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0029] (1) First, weigh 3g of PVA solid powder (degree of polymerization is 1750), add it to a container with deionized water, and continuously stir at 90°C to obtain a PVA solution with a mass fraction of 3%; then, weigh 50g of PVA The solution is placed in a beaker, add the cross-linking agent glutaraldehyde (0.05% of the mass of PVA), stir evenly, filter out the insoluble impurities, let it stand for defoaming to obtain the separation layer casting liquid, adjust the height of the scraper to 100 μm, and adjust the scraping speed of the film. 50m·min -1 , the casting liquid was carefully coated on the substrate, and dried at room temperature for 2 days to obtain a separation membrane;

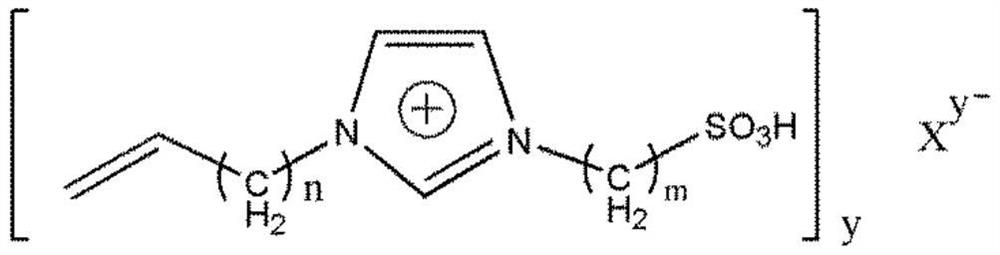

[0030](2) Take 30 g of PVA solution with a mass fraction of 3%, add a strongly acidic ionic liquid monomer 1-vinyl-3-sulfonic acid butylimidazole hydrochloride (the molar ratio of ILs to PVA is 0.1), place it at 60 In a constant temperature water bath at ℃, under the protection of nitrogen, ...

Embodiment example 2

[0034] (1) First weigh 5g of PVA solid powder (degree of polymerization is 2050), add it to a container with deionized water, and continuously stir at 95°C to obtain a PVA solution with a mass fraction of 5%; then, weigh 50g of PVA solution, add the cross-linking agent glutaraldehyde (0.1% of the mass of PVA), stir evenly, filter out the insoluble impurities, let stand for defoaming to obtain the separation layer casting liquid, adjust the height of the scraper to 100μm, and adjust the scraping speed to 10m·min -1 , the casting liquid was carefully coated on the substrate, and dried at room temperature for 3 days to obtain a separation membrane;

[0035] (2) take 30g of PVA solution whose mass fraction is 5%, add strong acid ionic liquid monomer 1-vinyl-3-sulfonic acid propyl imidazole hydrogen sulfate (mol ratio of ILs to PVA is 0.2), place it at 75 In a constant temperature water bath at ℃, under the protection of nitrogen, first purge for 30min, then add the initiator potas...

Embodiment example 3

[0039] (1) First, weigh 10g of PVA solid powder (degree of polymerization is 1750), add it to a container with deionized water, and continuously stir at 100°C to obtain a PVA solution with a mass fraction of 10%; then, weigh 30g of PVA solution, add cross-linking agent maleic acid (0.1% of the mass of PVA), stir at room temperature, filter out insoluble impurities, let stand for defoaming to obtain separation layer casting liquid, adjust the height of the scraper to 200μm, and the scraping speed to 5m· min -1 , the casting liquid was carefully coated on the substrate, dried at room temperature for 2 days, and finally a separation membrane with high separation performance was obtained;

[0040] (2) Take 30g of PVA solution with a mass fraction of 8%, add a strongly acidic ionic liquid monomer 1-enebutyl-3-sulfonic acid butylimidazolium trifluoromethanesulfonate (the molar ratio of ILs to PVA is 0.3 ), placed in a constant temperature water bath at 80°C, under the protection of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com