An arc welding method based on laser high frequency oscillation molten pool

An arc welding method and high-frequency oscillation technology, which are used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of limited additional effects and low laser oscillation frequency, and achieve uniform nucleation and improved crystal nucleation. Nucleation rate, effect of grain growth refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

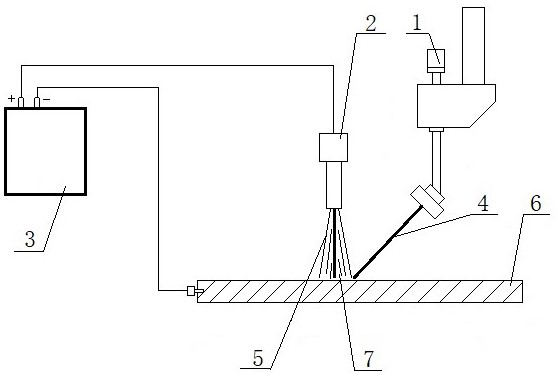

[0029] Embodiment 1, an arc welding method based on laser high-frequency oscillation molten pool, which includes the following steps:

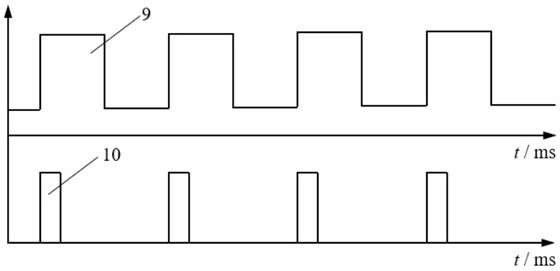

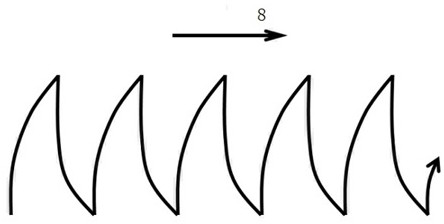

[0030] 1. The workpiece 6 to be welded is a 6mm thick 5052 aluminum alloy plate, and the ER5356 aluminum alloy welding wire with a diameter of 1.2mm is used as the wire material; the arc adopts a gas-shielded MIG arc, and the laser 1 is a Q-modulated Nd:YAG laser. The workpiece 6 to be welded is horizontally fixed on the welding platform, and the workpiece 6 to be welded is connected to the negative pole of the arc power supply 3 , and the metal wire is connected to the positive pole of the arc power supply 3 . Adjust the arc welding torch 2 so that the outgoing direction of the electric arc and the metal wire 5 forms an angle of 5° with the vertical plane, adjust the laser 1 so that the outgoing direction of the laser beam 4 and the electric arc 5 are symmetrically distributed along the plumb line, and the outgoing direction of the electric ar...

Embodiment 2

[0036] Embodiment 2, an arc welding method based on laser high-frequency oscillation molten pool, which includes the following steps:

[0037] 1. The workpiece 6 to be welded is a 2mm thick 5052 aluminum alloy plate, and the ER5356 aluminum alloy welding wire with a diameter of 1.0mm is used as the wire material; the arc adopts a gas-shielded MIG arc, the arc heat source travels at a speed of 10mm / s, and the shielding gas used is Pure argon, the flow rate of the shielding gas is 15L / min; laser 1 is a Q-modulated Nd:YAG laser. The workpiece 6 to be welded is horizontally fixed on the welding platform, and the workpiece 6 to be welded is connected to the negative pole of the arc power supply 3 , and the metal wire is connected to the positive pole of the arc power supply 3 . Adjust the arc welding torch 2 so that the outgoing direction of the electric arc and the metal wire 5 forms an angle of 5° with the vertical plane, adjust the laser 1 so that the outgoing direction of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com