Treatment process for mother liquor extraction liquid of purified terephthalic acid oxidation unit

A terephthalic acid and treatment process technology, applied in the field of industrial wastewater treatment, can solve the problems of large amount of alkaline substances, increased enterprise costs, waste of resources, etc., and achieve the effects of saving resources, increasing utilization rate, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

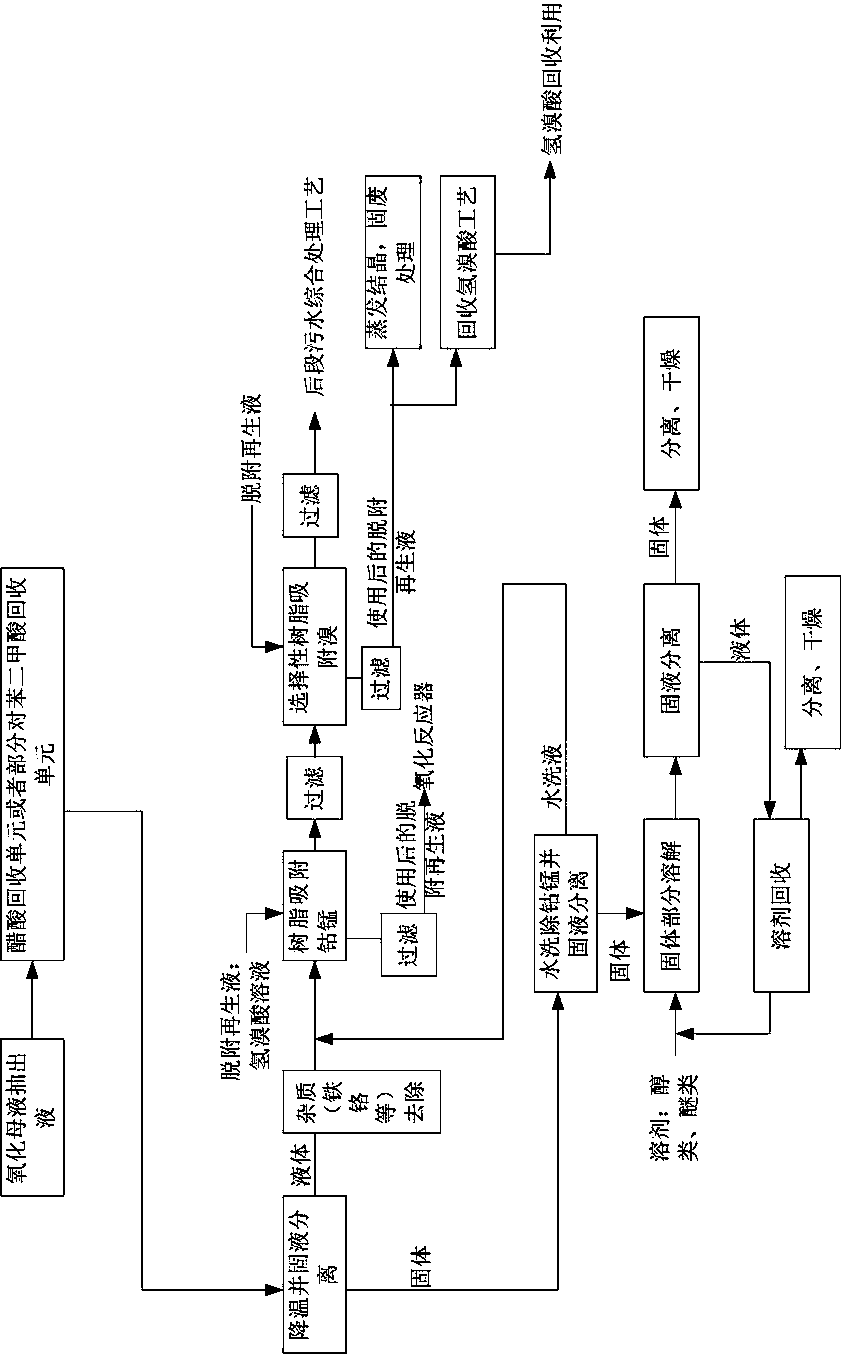

[0021] A treatment process for the mother liquor extraction liquid of the purified terephthalic acid oxidation unit, the process flow is:

[0022] Step a: The extraction liquid of the oxidation mother liquor passes through an acetic acid recovery processing unit or a terephthalic acid partial recovery processing unit to obtain sewage;

[0023] Step b: The sewage of step a is treated by lowering the temperature and separating solid-liquid to obtain a mixture and separated liquid containing phthalic acid and benzoic acid solids;

[0024] Step c: Transport the separation liquid to the impurity removal unit to remove iron and chromium ions in the separation liquid;

[0025] Step d: Then transfer the liquid of step c to the resin adsorption cobalt manganese unit, to adsorb the cobalt and manganese therein, and filter the effluent after the adsorption;

[0026] Step e: transport the effluent of step d to the bromine removal unit, adsorb bromine through an adsorption resin selective to bromine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com