High-strength antifreeze conductive polypyrrole hydrogel and preparation method thereof

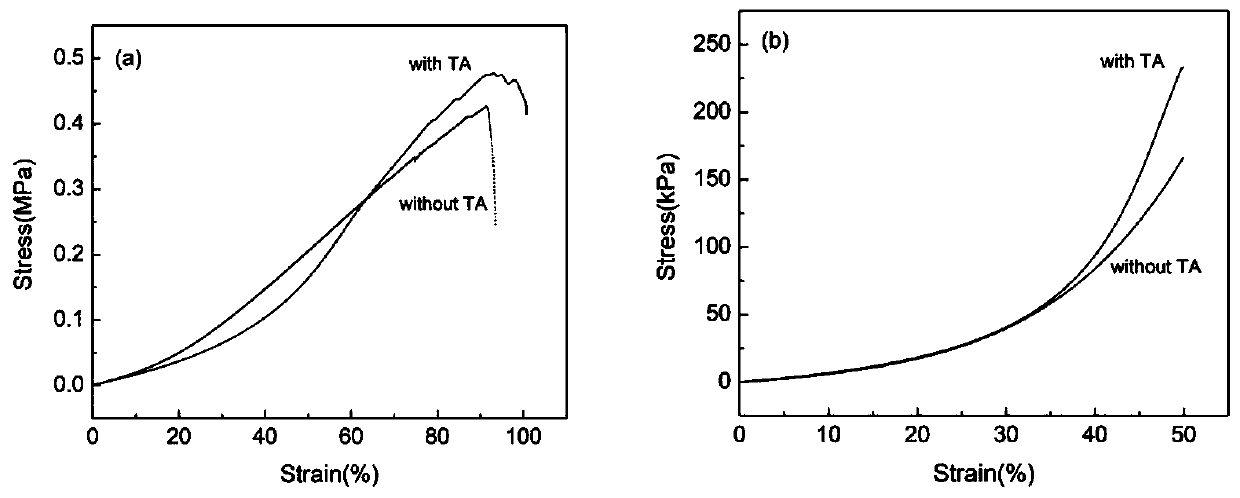

A conductive hydrogel and pyrrole hydrogel technology is applied in the field of high-strength antifreeze conductive polypyrrole hydrogel and its preparation, which can solve the disadvantages of wide-scale popularization, high price of dopamine modifiers, and complicated preparation process. problem, to achieve the effect of high toughness, low cost and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

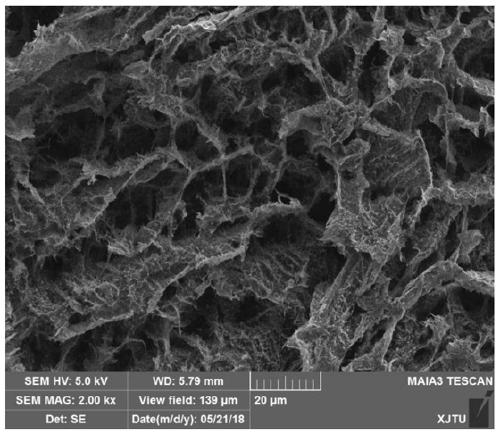

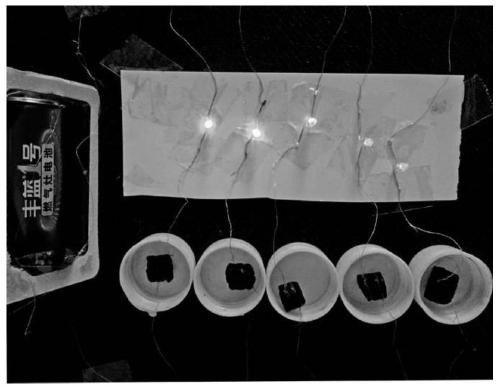

[0033] A preparation method of high-strength antifreeze conductive polypyrrole hydrogel, comprising the steps

[0034] 1) Dissolve 10 parts of PVA with a molecular weight of 67000 in 90 parts of deionized water, and divide the resulting solution into two parts (about 50 ml each); add 0.670 parts of pyrrole and 0.164 parts of methyl Orange, and 0.5 parts of tannic acid and 0.3 parts of gallic acid, apply ultrasonic waves to make the above-mentioned substances dissolve and disperse uniformly in the polymer stabilizer solution. Add 5.4 parts of ferric chloride to another part of the PVA solution, fully stir to dissolve and mix evenly;

[0035] 2) Quickly mix the two solutions obtained above, pour them into a sealed plastic mold immediately after fully stirring, place the mold together with the mold in an ice bath at -50°C for 8 hours, and then place it at -15°C for 72 hours;

[0036] 3) Take out the frozen sample, thaw it at room temperature, and then freeze and thaw it again. A...

Embodiment 2

[0039] A preparation method of high-strength antifreeze conductive polypyrrole hydrogel, comprising the following steps:

[0040] 1) Dissolve 7.5 parts of PVA with a molecular weight of 145,000 in 92.5 parts of deionized water, and divide the resulting solution into two parts (about 50ml each); add 0.67 parts of pyrrole and 0.1 part of methyl orange to one part of the PVA solution , 0.64 parts of ethyl orange and 0.5 parts of gallic acid, ultrasonic waves are applied to dissolve and disperse the above-mentioned substances in the PVA solution evenly. Add 2.7 parts of ferric chloride hexahydrate and 2.0 parts of ferric nitrate to another part of the PVA solution, fully stir to dissolve and mix evenly;

[0041] 2) Quickly mix the two solutions obtained above, and pour them into a sealed plastic mold immediately after fully stirring, freeze together with the mold in an ice bath at -50°C for 8 hours, and then place it in an environment of -10°C for 24 hours;

[0042] 3) Take out t...

Embodiment 3

[0045] A preparation method of high-strength antifreeze conductive polypyrrole hydrogel, comprising the following steps:

[0046] 1) Dissolve 5 parts of PVA with a molecular weight of 205,000 in 95 parts of deionized water, and divide the resulting solution into two parts (about 50 ml each); add 0.3 parts of pyrrole and 0.08 parts of methyl orange to one part of the PVA solution and 0.3 parts of ellagic acid, apply ultrasound to make the above-mentioned substances dissolve and disperse evenly in the PVA solution. Add 3.00 parts of ferric sulfate to another part of the polymer PVA solution, stir fully to dissolve and mix evenly;

[0047] 2) Quickly mix the two solutions obtained above, and pour them into a sealed plastic mold immediately after fully stirring, freeze together with the mold in an ice bath at -40°C for 10 hours, and then place it at -15°C for 24 hours;

[0048] 3) Take out the frozen sample, thaw it at room temperature, freeze and thaw it again, repeat the freezi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com