Method for using distilled residual liquid of pineapple brandy for brewing flavor fruit vinegar

A technology of brandy and pineapple, which is applied in the field of brewing flavored fruit vinegar by using the residual liquid of pineapple brandy distillation, which can solve the problems of environmental pollution and loss of nutrients, and achieve the effects of increasing quality, improving the types of nutrients, and enriching the taste of fruit vinegar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A method for brewing flavored fruit vinegar by utilizing pineapple brandy distillation raffinate, comprising the steps of:

[0069] a. Raw material processing: take fresh pineapple without rot and mildew as raw material, peel and cut into pieces after cleaning, place the cut pineapple pieces in a juice extractor to squeeze (adding a small amount of water and ascorbic acid), and filter to obtain Pineapple juice (take 10kg).

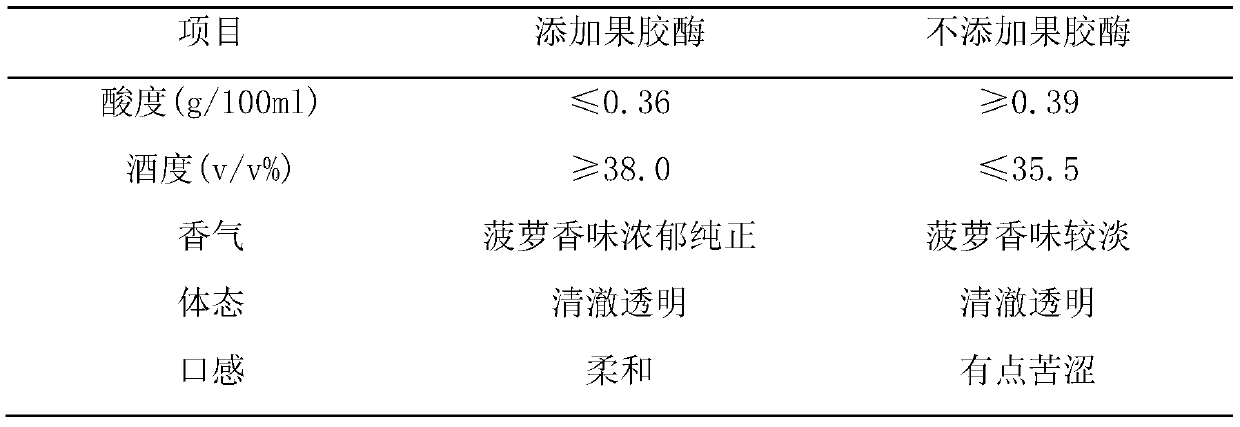

[0070] b. Enzymolysis: Add 0.003kg of pectinase to 10kg of pineapple juice, control the temperature at 55°C, pH at 4.5, and time for 1-2 hours.

[0071] c. Adding sugar: Add 0.3 kg of white granulated sugar to 10 kg of pineapple juice after enzymolysis, use it to adjust the initial sugar content to about 16%, and make a mixed slurry.

[0072] d. Juice sterilization: heat the juice to 68-75°C, keep this temperature for 30 minutes, and then rapidly cool it to 4-5°C.

[0073] e. Activation of yeast and acetic acid bacteria: Add commercially available...

Embodiment 2

[0081] A method for brewing flavored fruit vinegar by utilizing pineapple brandy distillation raffinate, comprising the steps of:

[0082] a. Raw material processing: take fresh pineapple without rot and mildew as raw material, peel and cut into pieces after cleaning, place the cut pineapple pieces in a juice extractor to squeeze (adding a small amount of water and ascorbic acid), and filter to obtain Pineapple juice (take 10kg).

[0083] b. Enzymolysis: Add 0.003 kg of pectinase to 10 kg of pineapple juice, control the temperature at 50° C., pH at 4.5, and time for 2 hours.

[0084] c. Adding sugar: Add 0.3 kg of white granulated sugar to 10 kg of pineapple juice after enzymolysis, use it to adjust the initial sugar content to about 16%, and make a mixed slurry.

[0085] d. Sterilization of fruit juice: heat the juice to 75°C, keep this temperature for 20 minutes, and then rapidly cool it to 4-5°C.

[0086] e. Activation of yeast and acetic acid bacteria: Add commercially a...

Embodiment 3

[0094] A method for brewing flavored fruit vinegar by utilizing pineapple brandy distillation raffinate, comprising the steps of:

[0095] a. Raw material processing: take fresh pineapple without rot and mildew as raw material, peel and cut into pieces after cleaning, place the cut pineapple pieces in a juice extractor to squeeze (adding a small amount of water and ascorbic acid), and filter to obtain Pineapple juice (take 10kg).

[0096] b. Enzymolysis: Add 0.003 kg of pectinase to 10 kg of pineapple juice, control the temperature at 55° C., pH at 4.5, and time for 1 h.

[0097] c. Adding sugar: Add 0.3 kg of white granulated sugar to 10 kg of pineapple juice after enzymolysis, use it to adjust the initial sugar content to about 16%, and make a mixed slurry.

[0098] d. Fruit juice sterilization: heat the fruit juice to 70°C, keep this temperature for 25 minutes, and then rapidly cool it to 4-5°C.

[0099] e. Activation of yeast and acetic acid bacteria: Add commercially av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com