Preparing method for L-2-aminobutyric acid

A technology of aminobutyric acid and threonine, which is applied in the field of enzyme catalysis, can solve problems not related to the conversion rate of L-2-aminobutyric acid, and achieve the effect of avoiding purification steps and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

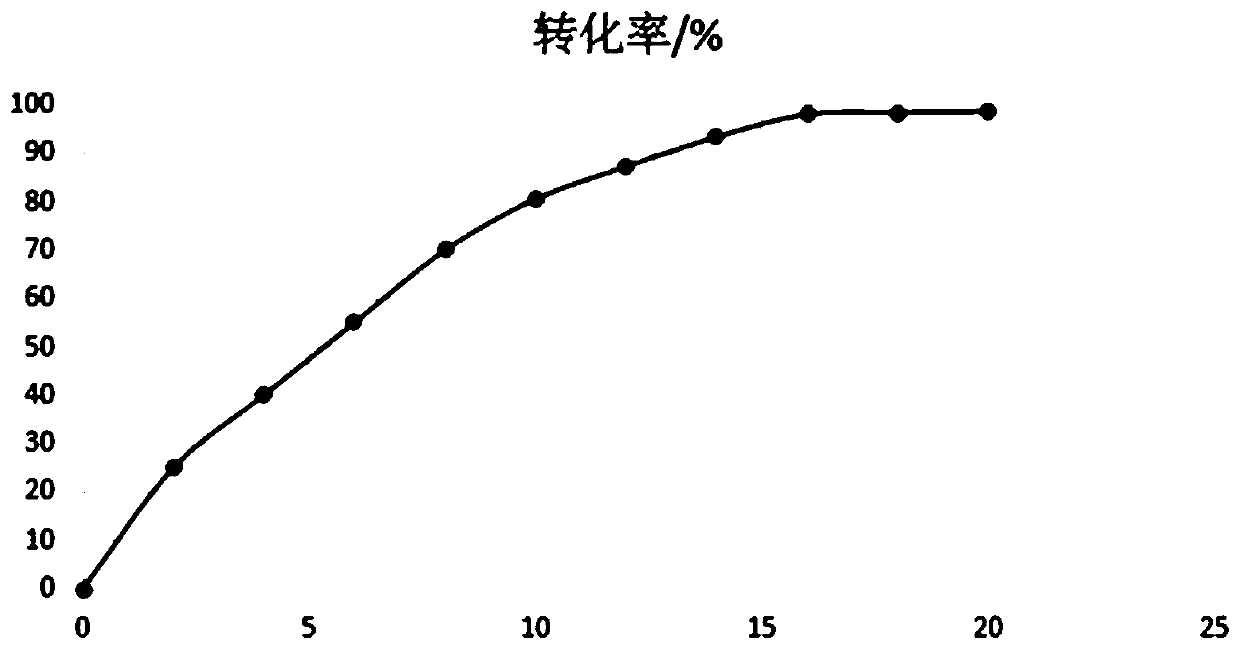

Image

Examples

Embodiment 1

[0021] Add 1200g of threonine, 1200g of ammonium formate, and ammonium dihydrogen phosphate into a 10L reactor, add water and stir to dissolve, then adjust the pH to 7.5 with 20-25% ammonia water, raise the temperature to 30°C, and then add threonine-producing deaminase , Leucine dehydrogenase and formate dehydrogenase sludge, wherein the concentration of phosphate ions is 20mmol / L, the total enzyme concentration in the mixed solution is 6U, and the mixed solution is stirred and reacted at a constant temperature of 30°C for 16h After the reaction is finished, L-aminobutyric acid solution is obtained.

Embodiment 2

[0023] Add 1200g of threonine, 600g of ammonium formate, and diammonium hydrogen phosphate into a 10L reaction kettle, add water and stir to dissolve, then adjust the pH to 7.5 with 20-25% ammonia water, raise the temperature to 30°C, and then add threonine-producing deaminase , Leucine dehydrogenase and formate dehydrogenase sludge, wherein the concentration of phosphate ions is 10mmol / L, the total enzyme concentration in the mixed solution is 4U, and the mixed solution is stirred and reacted at a constant temperature of 30°C for 20h After the reaction is finished, L-aminobutyric acid solution is obtained.

Embodiment 3

[0025] Add 1200g of threonine, 800g of ammonium formate, and sodium pyrophosphate into a 10L reaction kettle, add water and stir to dissolve, then adjust the pH to 7.7 with 20-25% ammonia water, raise the temperature to 30°C, and then add threonine-producing deaminase, Sludge of leucine dehydrogenase and formate dehydrogenase, wherein the concentration of phosphate ions is 15mmol / L, the total enzyme concentration in the mixture is 6U, the mixture is stirred and reacted at a constant temperature of 30°C, and after 18h After the reaction finishes, L-aminobutyric acid solution is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com