A quantum dot-based electronic nose chip and its design method

A design method and quantum dot technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low precision, low integration, high power consumption, etc., and achieve the effect of improving recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

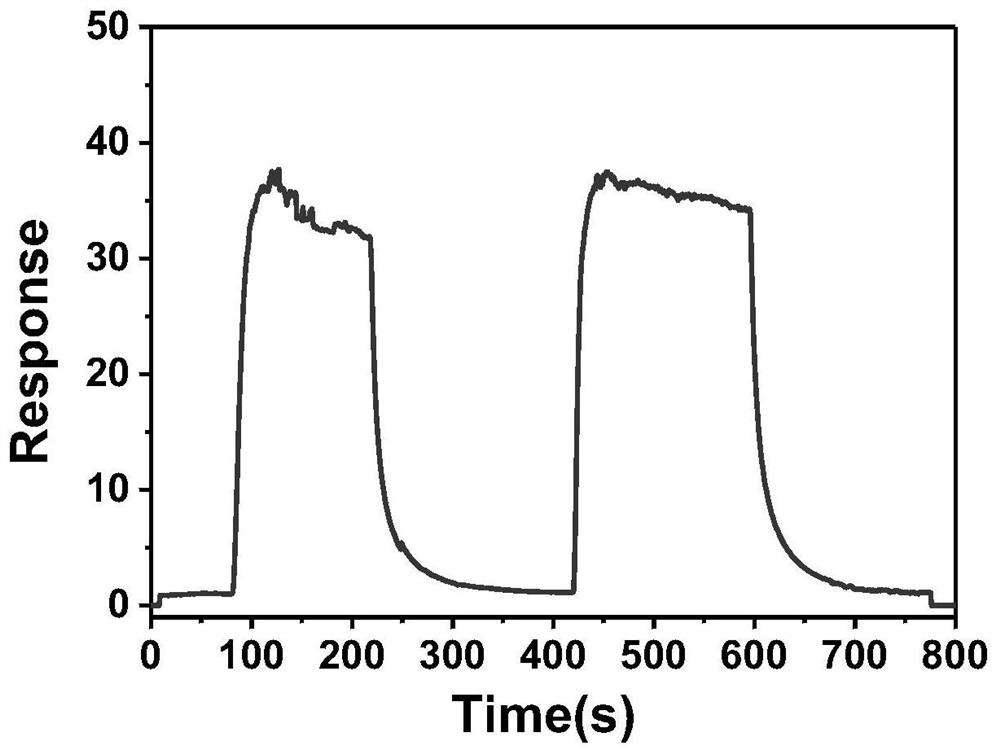

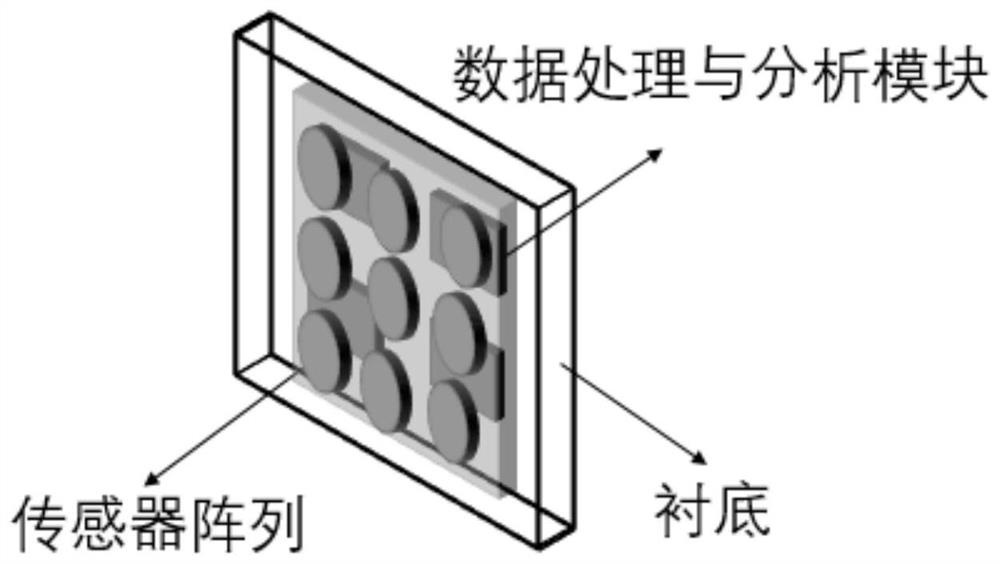

[0046] (1) Preparation of SnO 2 quantum dot material. where SnO 2 Quantum dots are made of SnCl 4 ·5H 2 O was used as tin source and synthesized by solvothermal method. Specifically, add 20ml oleic acid, 2.5ml oleylamine, 0.6g SnCl to a 50ml beaker 4 ·5H 2 O, ultrasonically stirred until the SnCl 4 ·5H 2 O is completely dissolved, then add 10ml of ethanol to it, continue ultrasonic stirring until the solution is uniformly dispersed, transfer the mixed solution to a stainless steel reaction kettle, react at 180°C for 8h, and then cool to room temperature through a cold water bath; collect the precipitate, and use Wash several times with absolute ethanol and toluene, disperse into toluene solution to obtain 20mg / ml SnO 2Quantum dot solution. (2) The quantum dot material is coated on the MEMS substrate to form a film by inkjet printing, and a resistive sensor unit is prepared. Based on this sensor unit, a MEMS sensor array is designed and prepared in combination with mic...

Embodiment 2

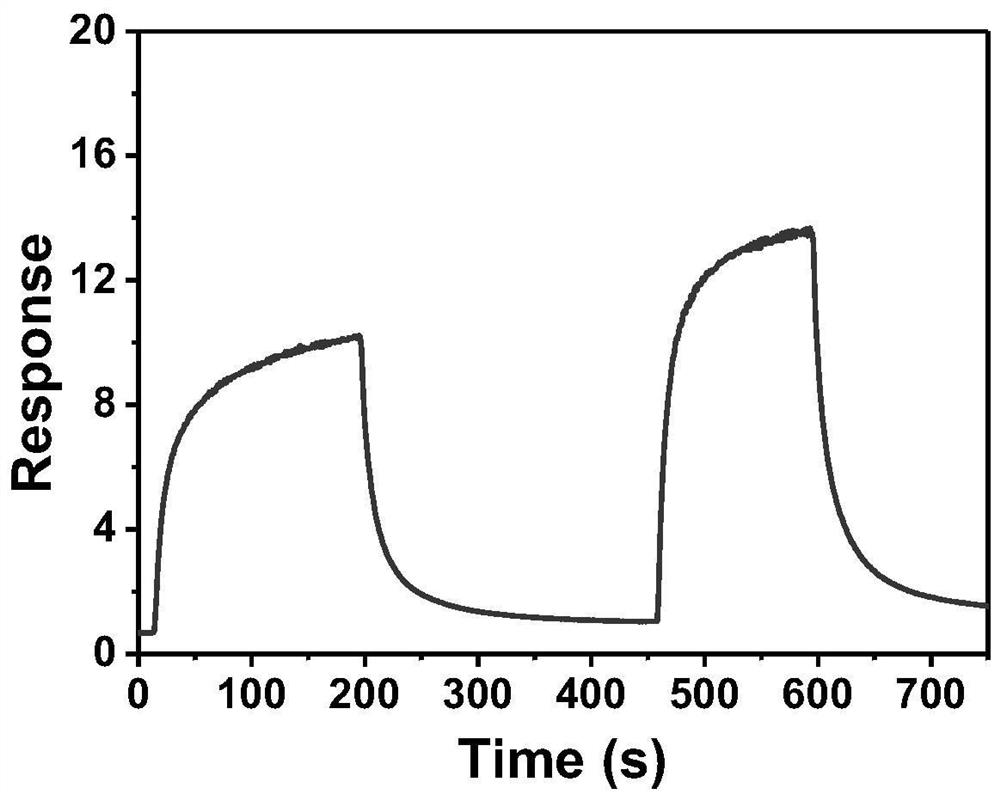

[0049] (1) Preparation of PbS quantum dot materials. Among them, Pbs quantum dots are synthesized by using PbO as a lead source, TMS as a sulfur source, and thermal injection. Specifically, 1.8 g of lead oxide, 6 mL of oleic acid, and 20 mL of octadecene were stirred in a three-necked flask at high speed, and the temperature of the precursor was raised to 120° C. after vacuuming. In the glove box, 280 uL of TMS was dissolved in 10 ml of octadecene with a pipette gun to prepare sulfur precursors. The sulfur precursor was quickly injected into the lead precursor in a nitrogen environment, reacted for 30 seconds and then placed in a cold water bath for rapid cooling. The precipitate was collected, washed several times with toluene acetone, and dispersed into n-octane solution to obtain a 20 mg / ml PbS quantum dot solution. (2) The quantum dot material is coated on the transistor to form a film by drop coating, and a sensor unit suitable for a field effect transistor is prepared....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com