High-voltage lithium cobaltate positive electrode material and preparation method thereof, and lithium ion battery

A positive electrode material, lithium cobalt oxide technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as dislocation, specific capacity and cycle performance deterioration, material structure distortion, etc., achieve high cycle stability, improve cycle Stability, the effect of slowing down the dissolution of cobalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Correspondingly, an embodiment of the present invention also provides a method for preparing a high-voltage lithium cobalt oxide positive electrode material, comprising the following steps:

[0060] S101, taking lithium source, cobalt source and a compound containing doping element Ma to prepare a mixture; said doping element Ma is selected from one of the elements with an ion radius range of 68pm-90pm, and an ion valence state ≥ 1 or various;

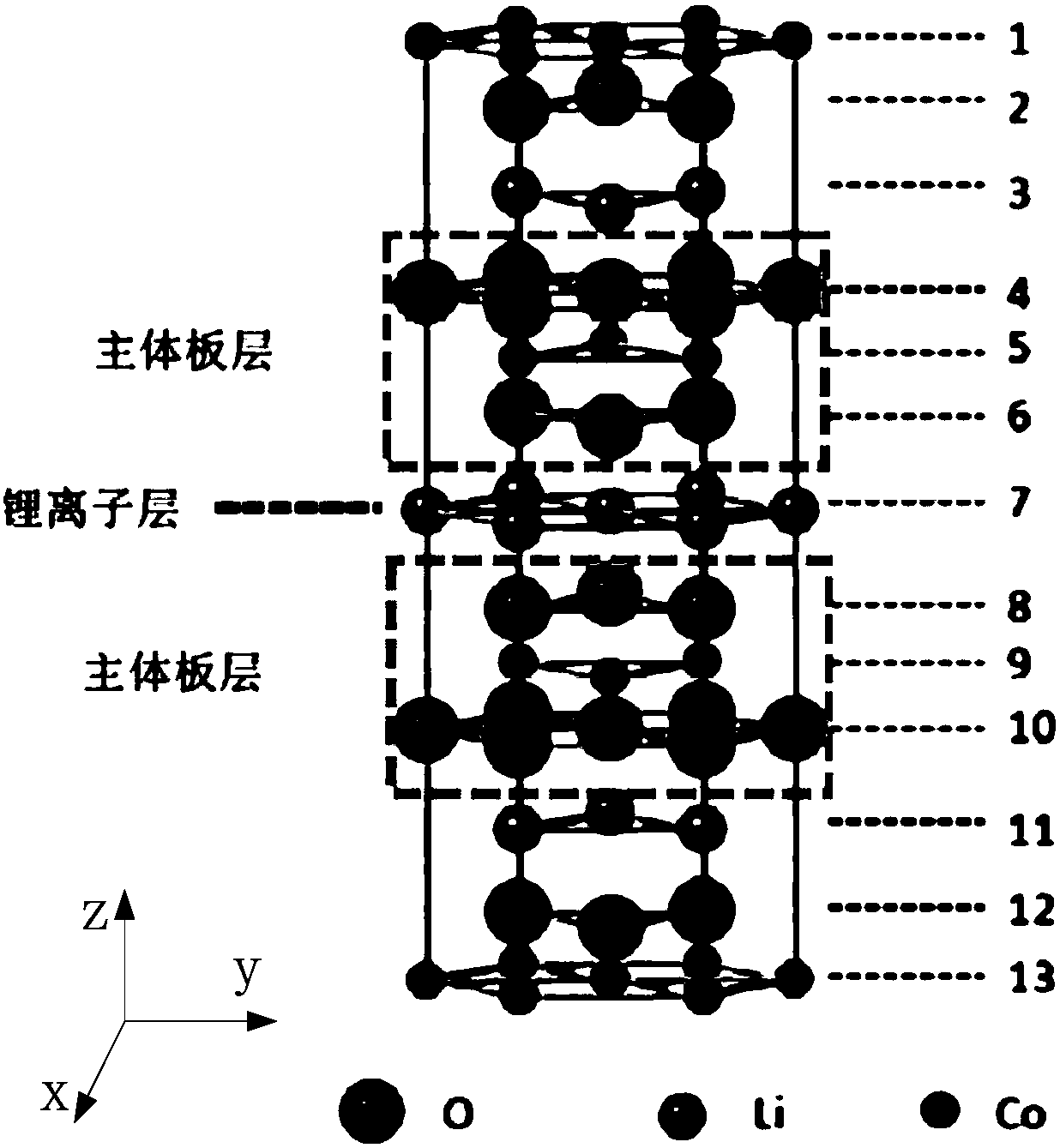

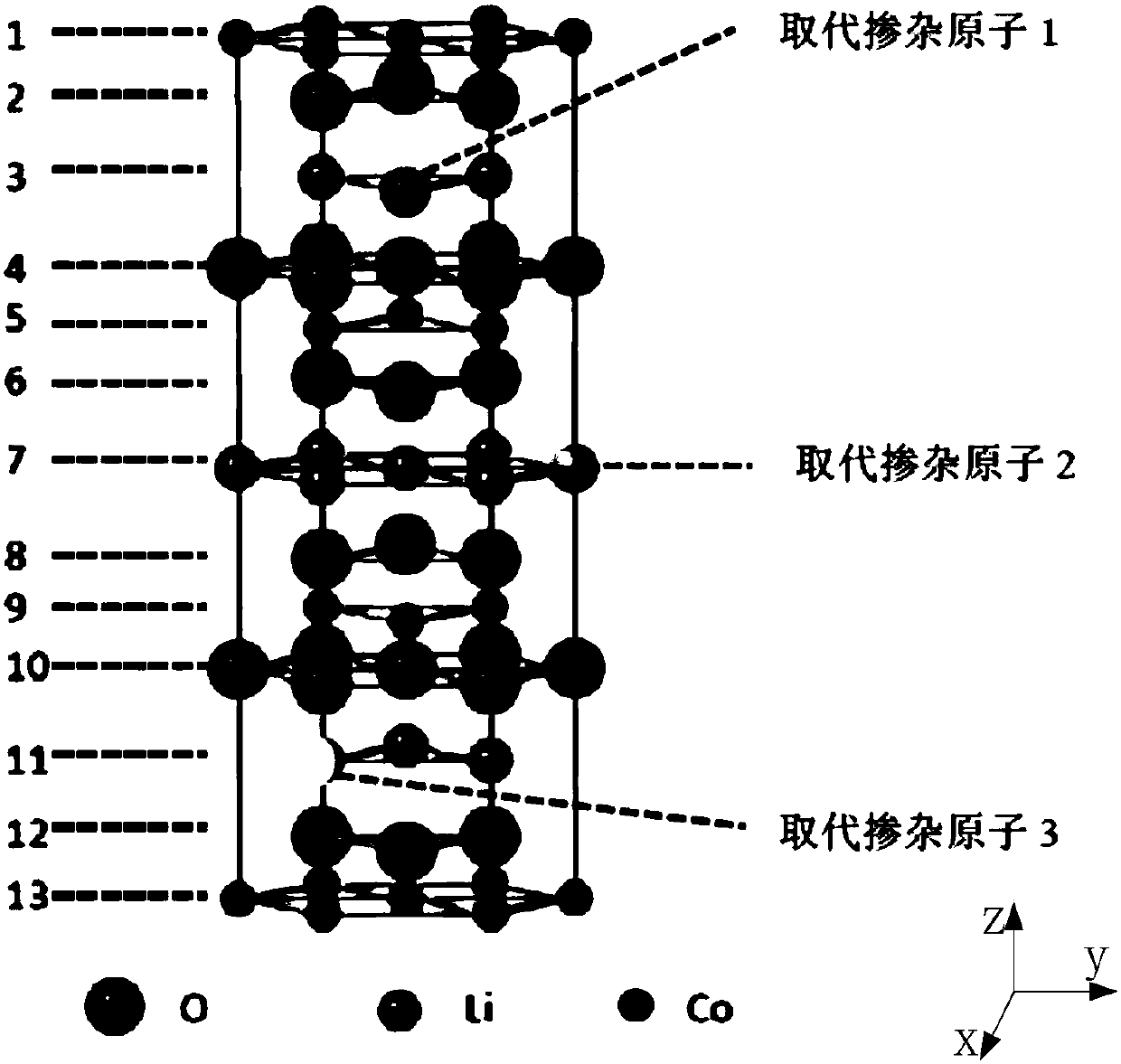

[0061] S102, sintering the mixture at 800°C-1100°C for 6-24 hours to obtain a crude product, and crushing the crude product to obtain lithium cobaltate doped with lithium substitution, that is, high-voltage cobaltate Lithium cathode material, the general formula of the lithium cobalt oxide doped by the substitution of lithium is: Li 1-x Ma x CoO 2 , wherein, 0<x≤0.05, the lattice of lithium cobalt oxide doped by lithium substitution includes a main body layer composed of a cobalt ion layer and an oxygen ion layer and lithium ...

Embodiment 1

[0071] A method for preparing a high-voltage lithium cobalt oxide positive electrode material, comprising the following steps:

[0072] (1) Preparation of Lithium Cobalt Oxide Lithium Substituted and Doped 0.95 Ni 0.05 COO 2

[0073] Take Li respectively 2 CO 3 ,Co 3 o 4 and Ni(OH) 2 , according to the molar ratio of lithium, cobalt and nickel 1.06:1:0.05, stir and mix evenly, place in a muffle furnace or sintering furnace for temperature sintering, keep it at 1050°C for 12h, collect the product after natural cooling, and carry out crushing collected to obtain nickel-doped lithium cobaltate Li 0.95 Ni 0.05 COO 2 One grain.

[0074] (2) with Li 0.95 Ni 0.05 COO 2 Preparation of High Voltage Lithium Cobalt Oxide Cathode Material with Primary Particles as Core

[0075] Get the nickel-doped lithium cobaltate Li prepared by step (1) 0.95 Ni 0.05 COO 2 20g, then soaked with ethanol and tiled onto a glass slide, and Li was deposited by atomic layer vapor deposition...

Embodiment 2

[0079] A method for preparing a high-voltage lithium cobalt oxide positive electrode material, comprising the following steps:

[0080] (1) Preparation of Lithium Cobalt Oxide Lithium Substituted and Doped 0.95 Mg 0.05 COO 2

[0081] Take Li respectively 2 CO 3 ,Co 3 o 4 and Mg(OH) 2 According to the molar ratio of lithium, cobalt and magnesium 1.06:1:0.05, feed materials, stir and mix evenly, place in muffle furnace or sintering furnace for temperature sintering, keep warm at 1050°C for 12 hours, collect products after natural cooling, and crush them collected to obtain magnesium-doped lithium cobaltate Li 0.95 Mg 0.05 COO 2 One grain.

[0082] (2) with Li 0.95 Mg 0.05 COO 2 Preparation of High Voltage Lithium Cobalt Oxide Cathode Material with Primary Particles as Core

[0083] Get the Mg-doped lithium cobaltate Li prepared by step (1) 0.95 Mg 0.05 COO 2 20g and nanoscale La 2 o 3 1g, mixed evenly by mechanical fusion method, placed in a muffle furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com