Cross-linked SBR microsphere adhesive, preparation method and lithium ion battery containing adhesive

A binder and cross-linking structure technology, applied in the direction of secondary batteries, battery electrodes, battery components, etc., can solve the problem of incomplete polymerization modification, difficult control of material stability, and incomplete and effective combination of carbon black, etc. problems, to achieve good adhesion, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

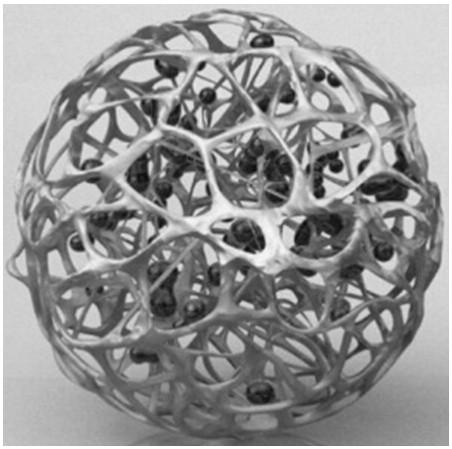

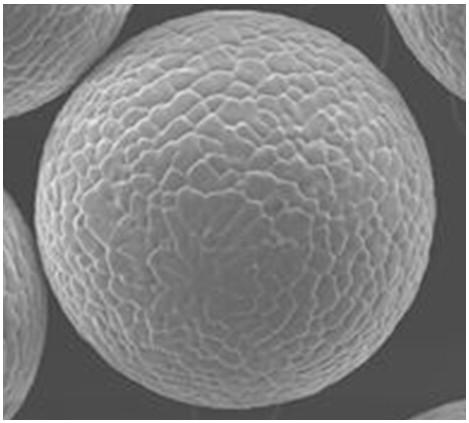

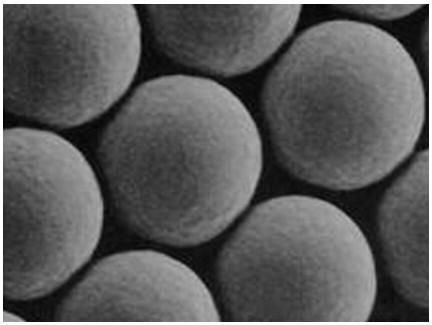

[0028] A cross-linked SBR microsphere binder, the cross-linked SBR microsphere has a porous cross-linked structure.

[0029] Further, the particle size range of the cross-linked SBR microspheres is 10nm-1um, preferably, the particle size range of the cross-linked SBR microspheres is 50nm-250nm.

[0030] Further, the porosity of the cross-linked SBR microspheres ranges from 0.01% to 40%.

[0031] Further, the pore diameter range of the pore is greater than 0 and less than or equal to 200nm, the pore includes micropores, mesopores and macropores, the pore diameter of the micropores is <2nm, the diameter of the mesopores is 2nm~50nm, and the diameter of the macropores is 50nm~200nm .

[0032] A preparation method of cross-linked SBR microsphere binder, comprising the steps of:

[0033] Step 1: Spray butadiene and styrene with sodium hydroxide aqueous solution with a mass fraction of 8%~16% at 20~40°C for 10min~4h, and then wash with deionized water until neutral to obtain deion...

Embodiment 1

[0049] A preparation method of cross-linked SBR microsphere binder, comprising the following steps:

[0050] Step 1: Spray butadiene and styrene with 8% sodium hydroxide aqueous solution at 20°C for 4 hours, and then wash with deionized water until neutral to obtain butadiene from which the polymerization inhibitor has been removed. olefin and deinhibited styrene;

[0051] Step 2: In parts by mass, 200 parts of deionized water, 25 parts of styrene, 80 parts of n-heptane, 20 parts of n-propanol, 20 parts of methyl alcohol, 40 parts of glycerol, 40 parts of Xylene, 75 parts of butadiene that removes the polymerization inhibitor are added to the reactor and stirred until uniformly mixed; add 0.16 parts of dodecyl mercaptan, 4.62 parts of disproportionated abietic acid soap, 0.15 parts of methylene bis-naphthalene Sodium sulfonate, 0.025 parts of sodium dithionite dihydrate, 0.24 parts of potassium phosphate, stir continuously until the mixture is uniform, and keep the temperatur...

Embodiment 2

[0057] A preparation method of cross-linked SBR microsphere binder, comprising the following steps:

[0058] Step 1: raw material pretreatment: including the purification of monomers and the configuration of initiators and other added components; butadiene and styrene were sprayed with 10% sodium hydroxide aqueous solution at 40°C for 10 minutes, Then deionized water is washed to neutrality to obtain the butadiene that removes the polymerization inhibitor and the styrene that removes the polymerization inhibitor; the butadiene that removes the polymerization inhibitor, porogen, modified monomer, and The combination of styrene, molecular weight regulator, deoxidizer, electrolyte, reducing agent, complexing agent, oxidizing agent, emulsifier and co-emulsifier, terminator and co-termination agent are respectively configured with deionized water to remove the polymerization inhibitor. Aqueous solution or emulsion, the concentration is not required; wherein, the porogen includes n-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com