Catalyst for decomposing formaldehyde and preparation method of catalyst

A catalyst and formaldehyde technology are applied in the field of catalysts for decomposing formaldehyde and their preparation, which can solve the problems of poor mechanical properties of catalyst carriers and low catalytic efficiency of catalysts, and achieve the effects of small particle size, promotion of oxidative decomposition and good mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

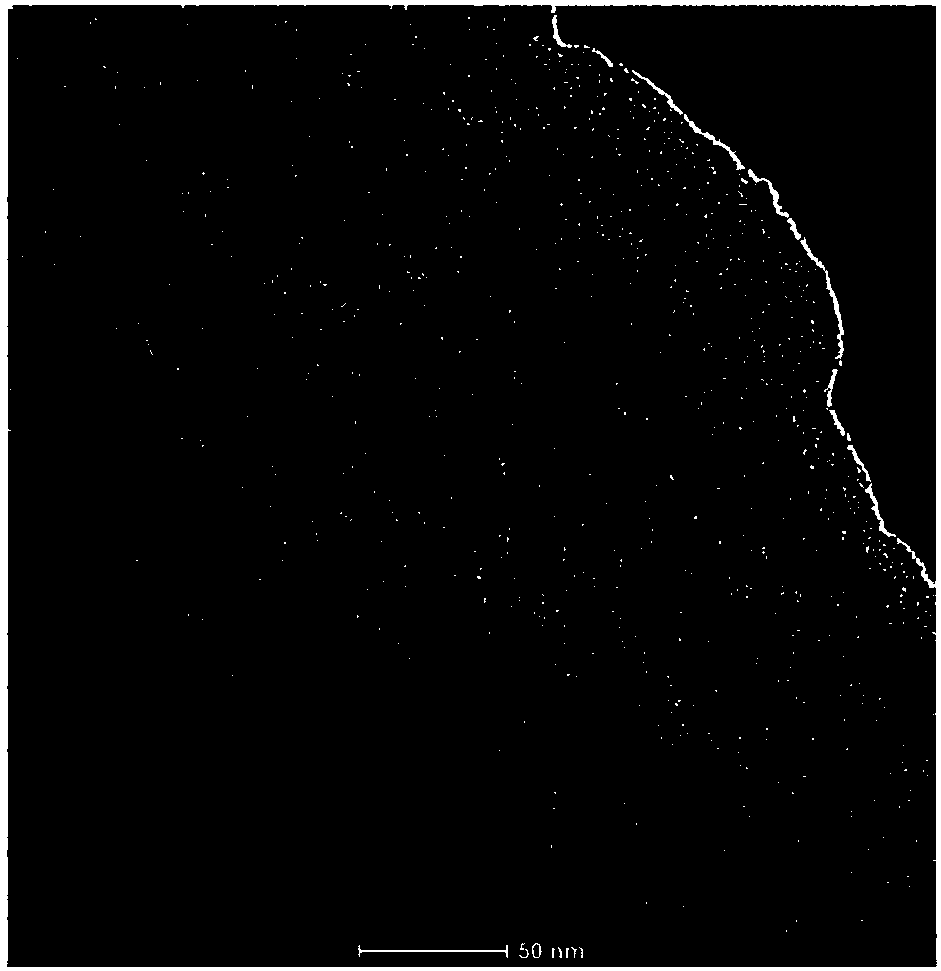

[0036] As another aspect of the present invention, a method for preparing a catalyst for decomposing formaldehyde is provided, comprising: a cleaning step of the cordierite honeycomb ceramic carrier: soaking the cordierite honeycomb ceramic carrier in an acid solution, and ultrasonically Drying after cleaning; preparation steps of subnano-scale noble metal particles: under the protection of the protective agent, use alcohol as a reducing agent to reduce the noble metal compound to sub-nano-scale noble metal particles to obtain a colloidal solution; preparation steps of the composite slurry: in the colloid Add oxygen storage metal oxide powder and polyethylene glycol into the solution and mix evenly to obtain a composite slurry; adsorption step: impregnate the cleaned cordierite honeycomb ceramic carrier in the composite slurry to make the subnano-scale noble metal particles and storage Oxygen metal oxide is adsorbed on the surface of the cordierite honeycomb ceramic carrier; dr...

Embodiment 1

[0048] In the preparation method of this embodiment, the cleaning step of the cordierite honeycomb ceramic carrier is firstly performed: soaking the cordierite honeycomb ceramic carrier in an acid solution, ultrasonic cleaning in deionized water, and drying, the acid solution is 10% by mass percentage nitric acid solution, the soaking time is 15min, the ultrasonic cleaning time in deionized water is 30min, the drying temperature is 50°C, and the drying time is 8h; As a reducing agent, the noble metal compound is reduced to sub-nanometer noble metal particles to obtain a colloidal solution. The protective agent is polyvinylpyrrolidone, the alcohol is methanol, and the noble metal compound is chloroplatinic acid. Dissolve polyvinylpyrrolidone in water, and 6mg of polyvinylpyrrolidone corresponds to 5ml of deionized water, correspondingly add 1ml of chloroplatinic acid solution with a concentration of 6g / L, add alcohol to the reaction solution at a volume ratio of alcohol to water...

Embodiment 2

[0050] In the preparation method of this embodiment, the cleaning step of the cordierite honeycomb ceramic carrier is firstly performed: soaking the cordierite honeycomb ceramic carrier in an acid solution, ultrasonic cleaning in deionized water, and drying, the acid solution is 20% by mass percentage nitric acid solution; soaking time is 30min; ultrasonic cleaning time in deionized water is 60min; drying temperature is 70°C, drying time is 14h; As a reducing agent, the noble metal compound is reduced to sub-nanometer noble metal particles to obtain a colloidal solution. The protective agent is polyvinylpyrrolidone, the alcohol is ethanol alcohol, and the noble metal compound is chloroplatinic acid. Dissolve polyvinylpyrrolidone in water, 10mg polyvinylpyrrolidone Corresponding to 10ml of deionized water, correspondingly add 5ml of chloroplatinic acid solution with a concentration of 12g / L, add alcohol to the reaction solution at a volume ratio of alcohol to water of 9:1, and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com