Graphene oxide composite membrane with pH responsiveness and preparation method and application thereof

A graphene composite, responsive technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effects of excellent separation performance, maintaining responsive performance, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 (MB)

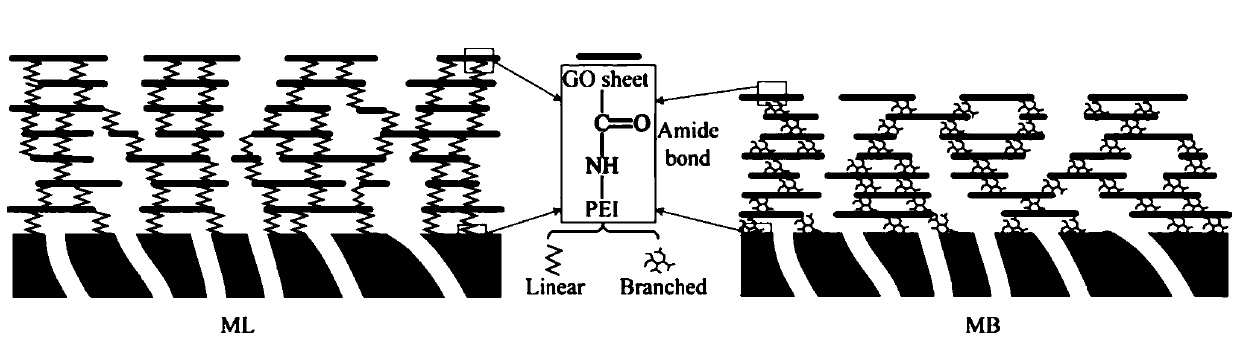

[0049] The pH-responsive graphene oxide composite film is realized by self-assembling graphene oxide sheets and polyethyleneimine layer by layer on the surface of the substrate. The specific structure is as follows: figure 1 shown. The specific preparation method is as follows:

[0050] (1) Add a certain amount of graphene oxide (GO) and polyvinylidene fluoride (PVDF) into dimethylacetamide (DMAc), the mass fraction of graphene oxide is controlled to be 0.2%, and the mass fraction of PVDF is 16 %, ultrasonically for one hour to disperse it.

[0051] (2) Stir the above mixture at 70° C. for 24 hours to obtain a uniformly mixed casting solution.

[0052] (3) Centrifuge the casting solution at 3000 rpm for 5 minutes to defoam, and then pass the casting solution through a scraping device to prepare a graphene oxide composite film with a thickness of 200 μm.

[0053] (4) Place the film prepared in step (3) in water, and then dry it to obtain a graphene o...

Embodiment 2

[0058] Example 2 (ML)

[0059] Compared with Example 1, the present embodiment is only different in that the branched polyethyleneimine in steps (5) and (7) is replaced by linear polyethyleneimine, and all the others are the same, and the polyethylenimine finally obtained is Ethyleneimine is a linear graphene oxide composite film, denoted as ML.

[0060] The preparation method of linear polyethyleneimine is as follows: polyethylene oxide is added to HCl solution, and the mixture is heated to 100° C. in a microwave digester for 4 hours. After the mixture was cooled to room temperature, the reaction product was collected and purified by dialysis, and finally, the purified product was freeze-dried to obtain linear polyethyleneimine.

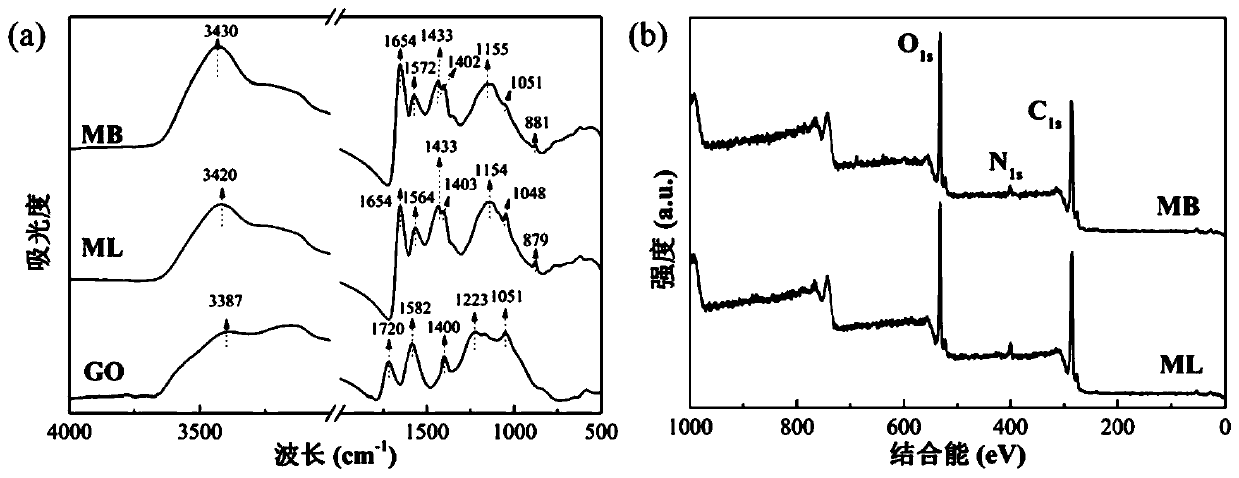

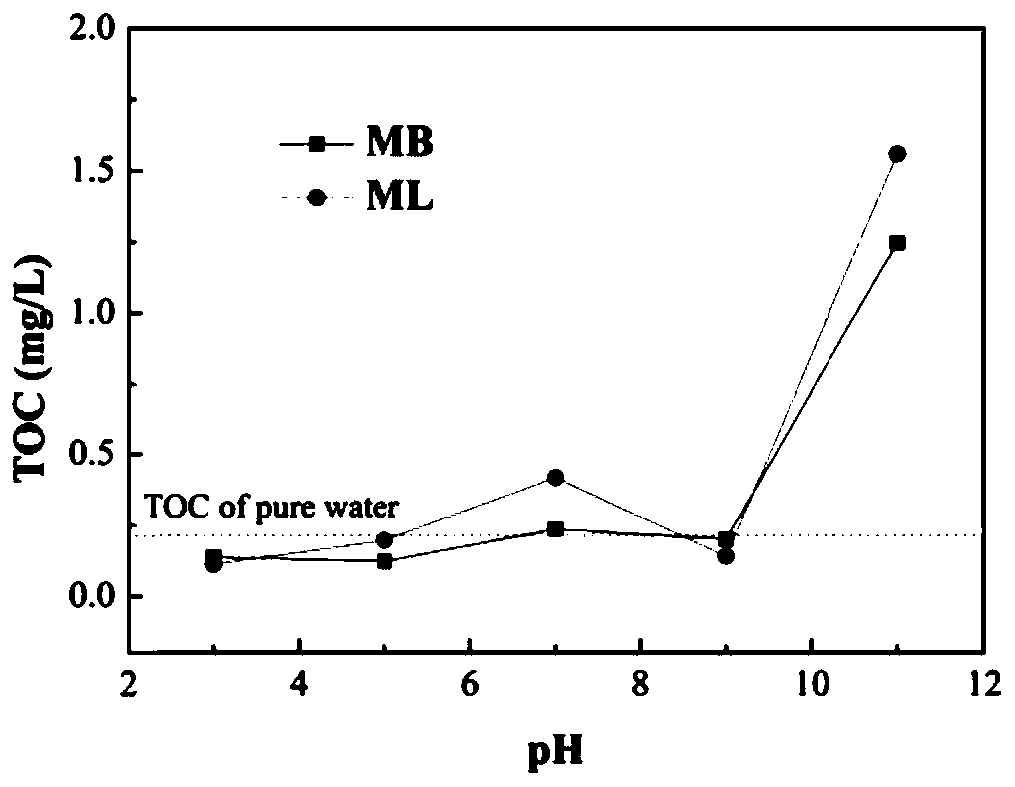

[0061] The graphene oxide composite film of above-mentioned embodiment 1 and 2 gained is carried out infrared spectrum and XPS collection of collection of collections to detect the chemical composition of its surface, the result is as follows fig...

Embodiment 3

[0069] Embodiment 3: interception of single component organic pollutant

[0070] In order to evaluate the screening effect of graphene oxide composite membranes under different pH conditions, several representative organic pollutants were selected for separation experiments, including polyvinylpyrrolidone (PVP, molecular weight 58K), polyethylene oxide (PEO, Molecular weights of 300K and 600K) and silver nanoparticles (Ag NPs, with a size of 50 nm), the above four pollutants were stable in the pH range from 3 to 11. like Figure 9 As shown, the rejection rates of MB and ML to the above four pollutants all increased with the increase of pH. When the pH of the solution changed from 3 to 11, the retention rates of MB and ML to PVP increased from <1% to 45.5% and from 1.5% to 26.4%, respectively; the retention rates of MB and ML to PEO1 (300K) were increased from 29.6 % became 88.7% and increased from 32.6% to 81.7%; the rejection of PEO2(600K) by MB and ML increased from 56.7% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com