Hierarchical porous activated carbon prepared from paper mill sludge composite kawo kawo fibers and preparation method of hierarchical porous activated carbon

A technology of kapok fiber and papermaking sludge, which is applied in the field of materials, can solve the problems of low specific gravity of kapok fiber, inability to be effectively utilized, and low yield of activated carbon, and achieve excellent adsorption rate, wide pore size distribution, and convenient implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

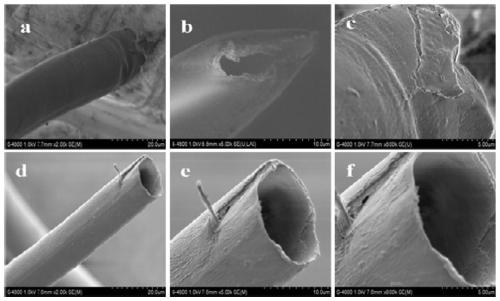

[0034] (1) Cut the kapok fiber irregularly to a dispersed state and mix it with papermaking sludge for 15 minutes until the mixing degree is uniform to obtain composite sludge; the kapok fiber has a hollowness of 90% and a length of about 250 μm; papermaking The moisture content of the sludge is 20%, and the particle size range is about 3mm; the composite volume ratio of sludge and kapok is 2:1;

[0035] (2) Send the composite sludge into the rotary dryer for drying, take it out and stir it and cut it properly; send it into the dryer again for drying until it is completely dry, take it out and pulverize it for use;

[0036] (3) According to the mass ratio of composite sludge to anhydrous sodium carbonate of 4:1, add the dried and pulverized composite sludge obtained in step (3) into anhydrous sodium carbonate solution, mix well and form a muddy impregnation 12h, drying at 110°C for 12h to obtain flocculated composite sludge;

[0037] (4) Feed the flocculated composite sludge ...

Embodiment 2

[0043] (1) Cut the kapok fiber irregularly to a dispersed state and mix it with papermaking sludge for 20 minutes until the mixing degree is uniform to obtain composite sludge; the kapok fiber has a hollowness of 95% and a length of about 500 μm; papermaking The moisture content of the sludge is 15%, and the particle size range is about 2mm; the composite volume ratio of sludge and kapok is 4:1;

[0044] (2) Send the composite sludge into the rotary dryer for drying, take it out and stir it and cut it properly; send it into the dryer again for drying until it is completely dry, take it out and pulverize it for use;

[0045] (3) According to the mass ratio of composite sludge to anhydrous sodium carbonate of 5:1, add the dried and pulverized composite sludge obtained in step (3) into anhydrous sodium carbonate solution, mix well and form a muddy impregnation 14h, drying at 120°C for 10h to obtain flocculated composite sludge;

[0046] (4) Send the flocculated composite sludge ...

Embodiment 3

[0051] (1) Cut the kapok fiber irregularly to a dispersed state and mix it with papermaking sludge for 10 minutes until the mixing degree is uniform to obtain composite sludge; the kapok fiber has a hollowness of 85% and a length of about 50 μm; papermaking The moisture content of the sludge is 20%, and the particle size range is about 5mm; the composite volume ratio of sludge and kapok is 4:1;

[0052] (2) Send the composite sludge into the rotary dryer for drying, take it out and stir it and cut it properly; send it into the dryer again for drying until it is completely dry, take it out and pulverize it for use;

[0053] (3) According to the mass ratio of composite sludge to anhydrous sodium carbonate of 5:1, add the dried and pulverized composite sludge obtained in step (3) into anhydrous sodium carbonate solution, mix well and form a muddy impregnation 14h, drying at 120°C for 10h to obtain flocculated composite sludge;

[0054] (4) Send the flocculated composite sludge i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

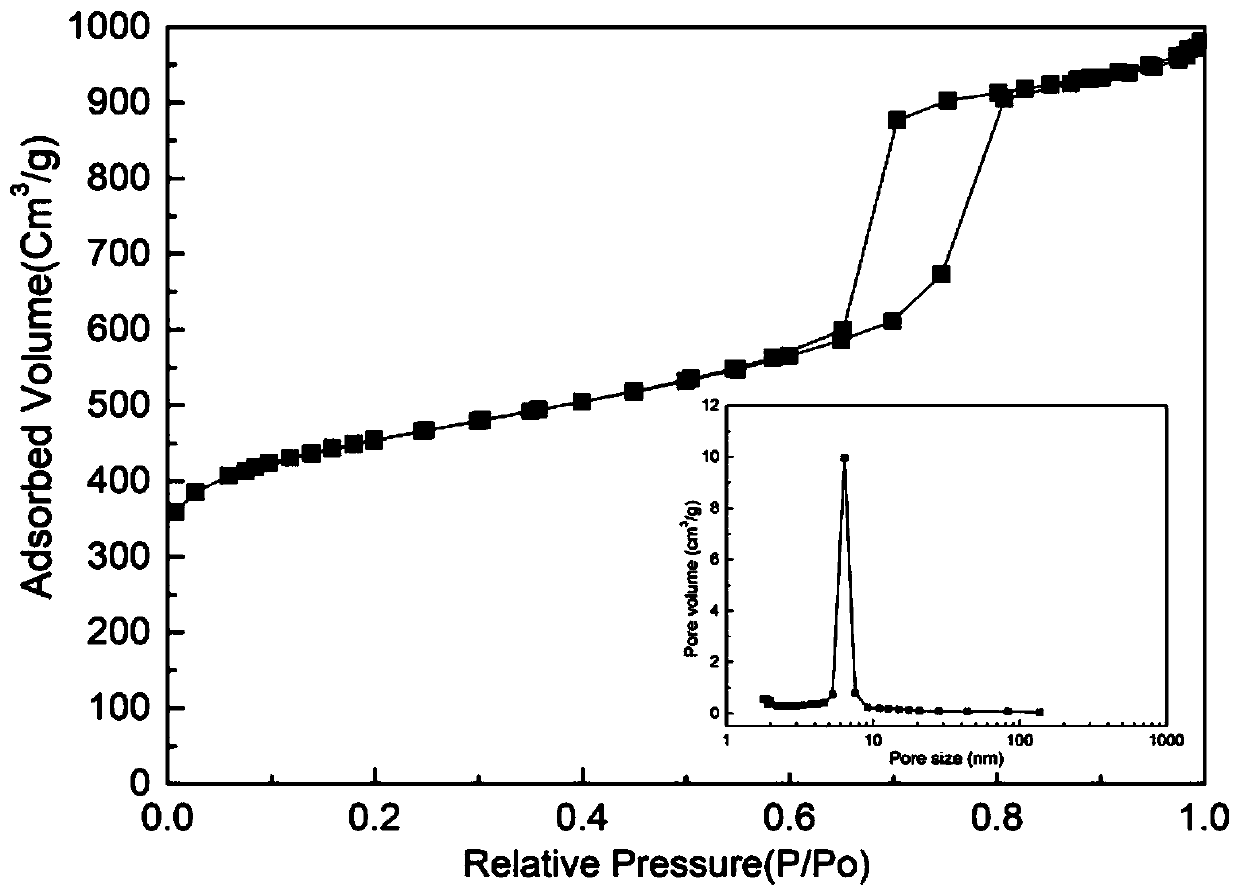

| Pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com