A kind of preparation method and application of microbial fermentation source flavor supplement

A microbial fermentation and supplement technology, applied in the field of food processing, can solve the problems of unstable product quality, high cost, long production cycle, etc., to avoid the growth of miscellaneous or harmful bacteria, save production time, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

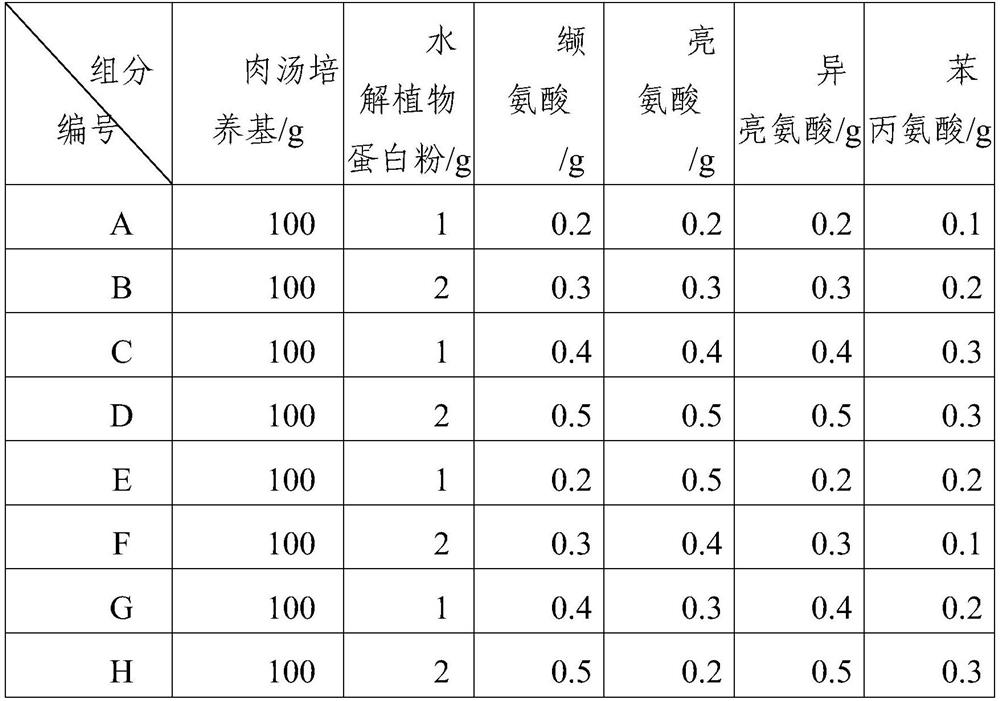

[0038] Specific media formulations containing amino acids

[0039] Table 1 provides several specific medium formulations containing amino acids

[0040] Table 1

[0041]

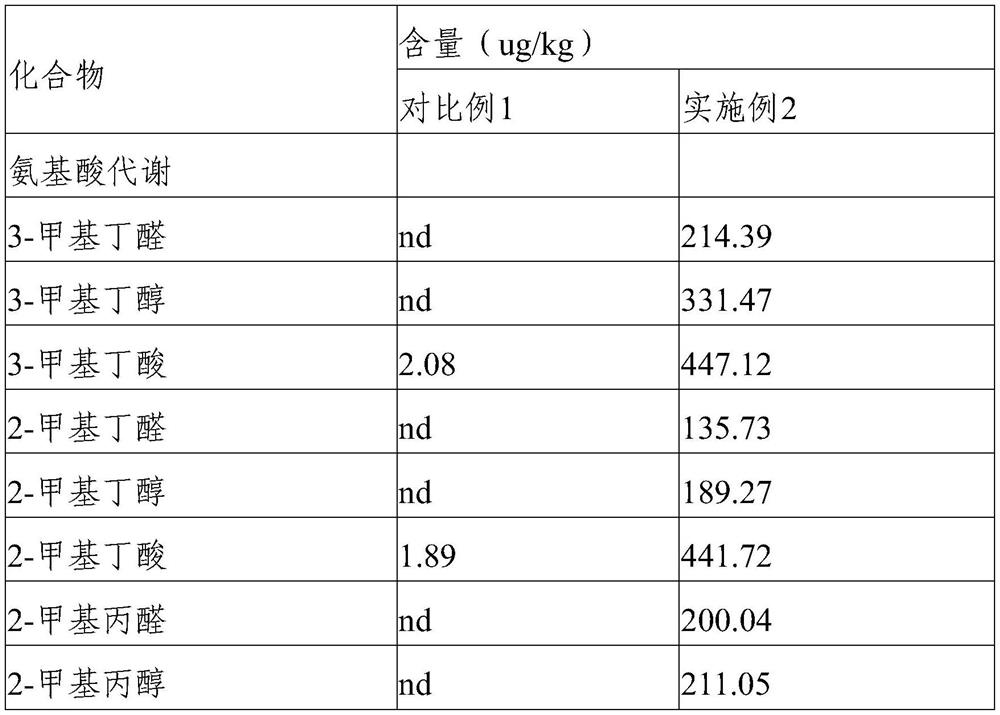

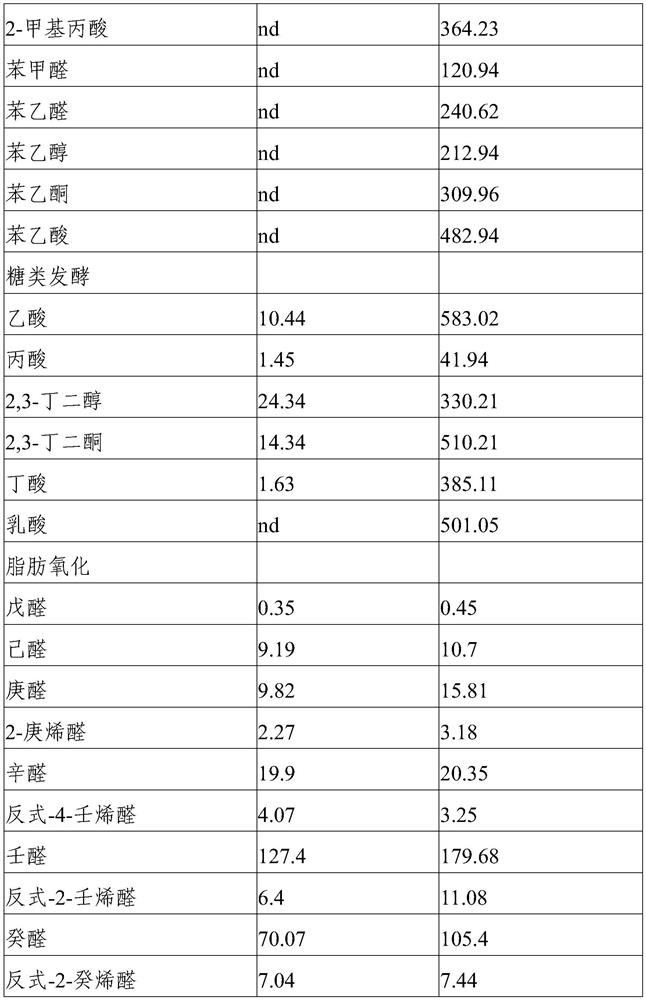

Embodiment 2

[0043] A kind of preparation method of flavor supplement

[0044] 1) Bacteria rejuvenation and enrichment:

[0045] Preparation of nutrient broth: Take fresh pork with fat and fascia removed, cut into pieces and mince, homogenize pork and water in a ratio of 1:3, boil for 30 minutes, and filter to obtain pork soup. Take 1kg pork soup, 20g glucose, 7g salt, boil and dissolve for later use.

[0046] Rejuvenation and enrichment method: Inoculate the nutrient broth with mixed staphylococcus powder (Staphylococcus caryosae and Staphylococcus xylos) and Lactobacillus plantarum powder respectively, the inoculation amount is 10 5 and 10 4 CFU / ml, shaking culture at 30°C for 6h.

[0047] 2) Staphylococcus fermentation broth

[0048] Specific medium containing 4 kinds of amino acids: 120 parts of nutrient broth, 2 parts of hydrolyzed vegetable protein powder, 0.4 parts of valine, 0.5 parts of leucine, 0.3 parts of isoleucine, 0.2 parts of phenylalanine, 0.1 part of used M dipotassi...

Embodiment 3

[0055] A kind of industrialized preparation method of bacon with traditional flavor

[0056] This embodiment provides an industrialized preparation method of bacon with traditional flavor. Among them, the formula is as follows:

[0057] Raw meat: pork belly 200kg.

[0058] Pre-prepared pickling liquid: flavor supplement 10kg, sodium erythorbate 0.2kg, sodium nitrite 0.04kg, complex phosphate 0.1kg, salt 5.0kg, sugar 1kg, glucose 1kg, liquor 1.5kg, papain 0.1kg, neutral fat Enzyme 0.1kg, mix well, 4 ℃ for use.

[0059] Flavor Supplement: The recipe D in Table D of Example 1 and the preparation method of flavor supplement described in Example 2 were adopted.

[0060] The preparation method includes the following steps:

[0061] Raw meat processing: cut the pork into strips;

[0062] Brine injection-vacuum tumbling and marinating: the weight ratio of marinating liquid to raw meat is 2:21. Use a salt water injection machine to evenly inject the meat into the meat, put the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com