Preparation method of wear-resistant composite material with nanometer gradient fiber reinforcement

A composite material and fiber reinforced technology, which is applied in the field of functional composite material manufacturing, can solve the problems of increasing the manufacturing cost of composite material structure, increasing the weight of composite material structure, and poor bonding of composite material matrix, so as to improve the interlaminar shear performance, The effect of saving material usage rate and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

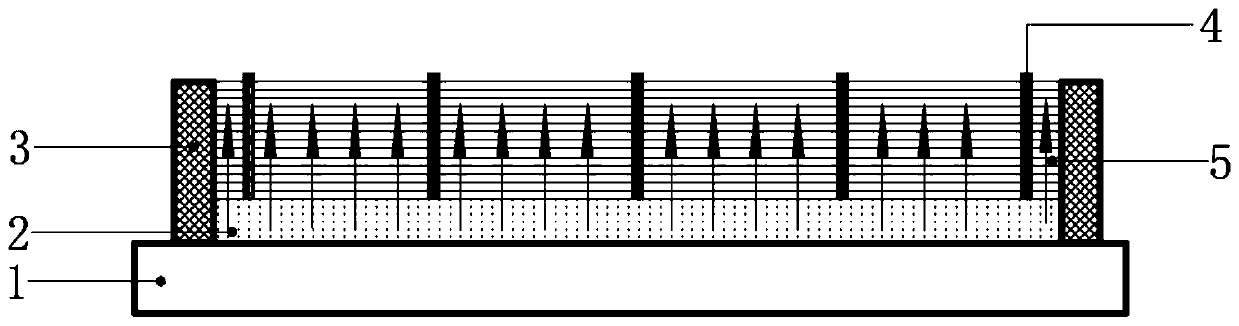

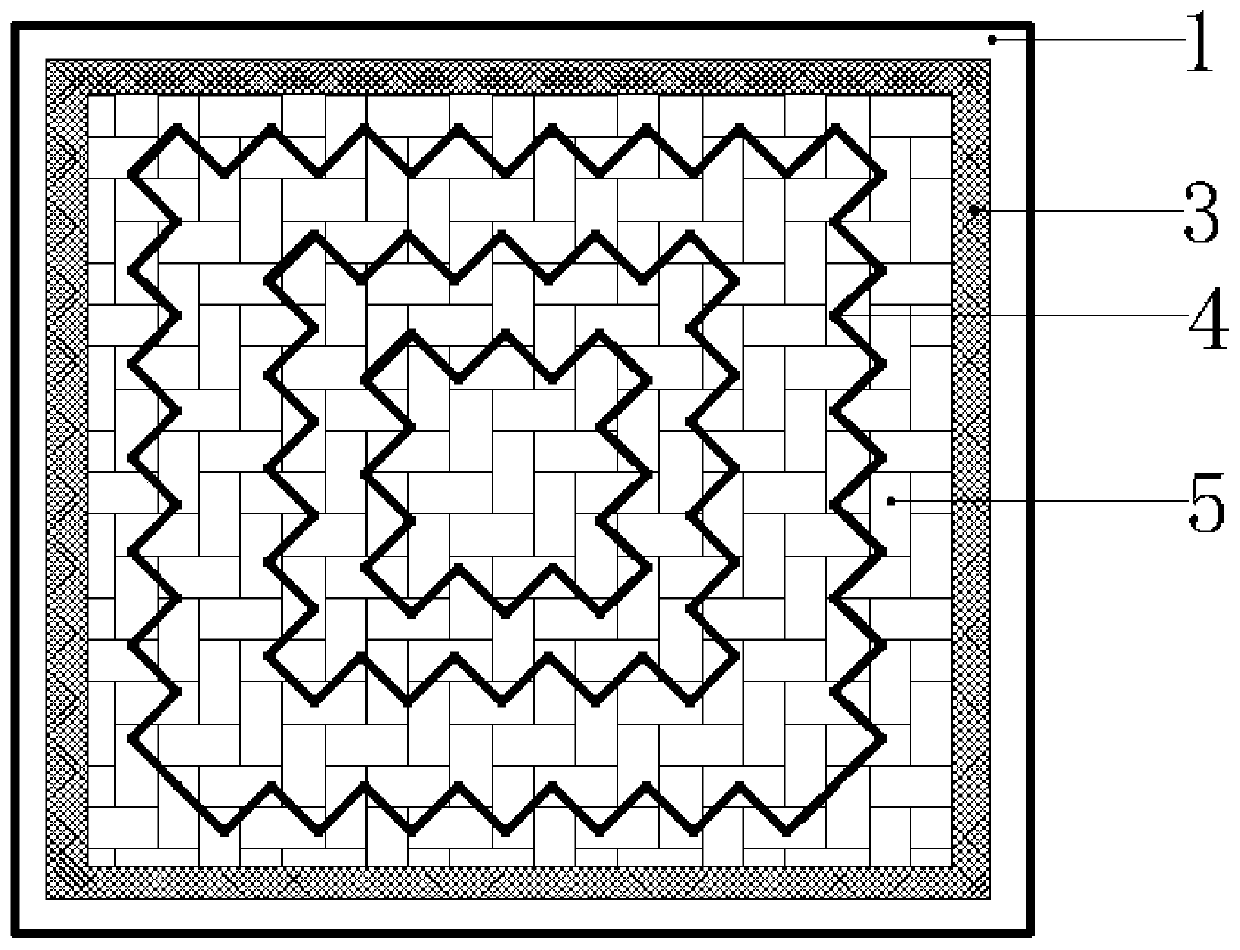

Image

Examples

preparation example Construction

[0036] 1) Preparation of resin film dispersed with nano wear-resistant particles

[0037] Mix and disperse the nano-wear-resistant particles and the resin containing solvent under a high-speed mixer for 2-3 hours, then dissolve the film-forming agent in the dispersed nano-wear-resistant particles and resin mixture, and select high temperature according to the performance setting The curing agent is mixed, and finally, the obtained resin system (that is, the resin dispersed with nano wear-resistant particles) is poured on an iron plate at 90-120°C, and cast to form a resin film containing dispersed nano wear-resistant particles;

[0038] The wear-resistant nanoparticles are one or more of graphene nanoparticles, boron nitride nanoparticles, and silicon carbide nanoparticles.

[0039] The surface of wear-resistant nanoparticles can be modified through different processes to meet the wear resistance requirements of parts, such as surface grafting, oxidation, etc., but not limited...

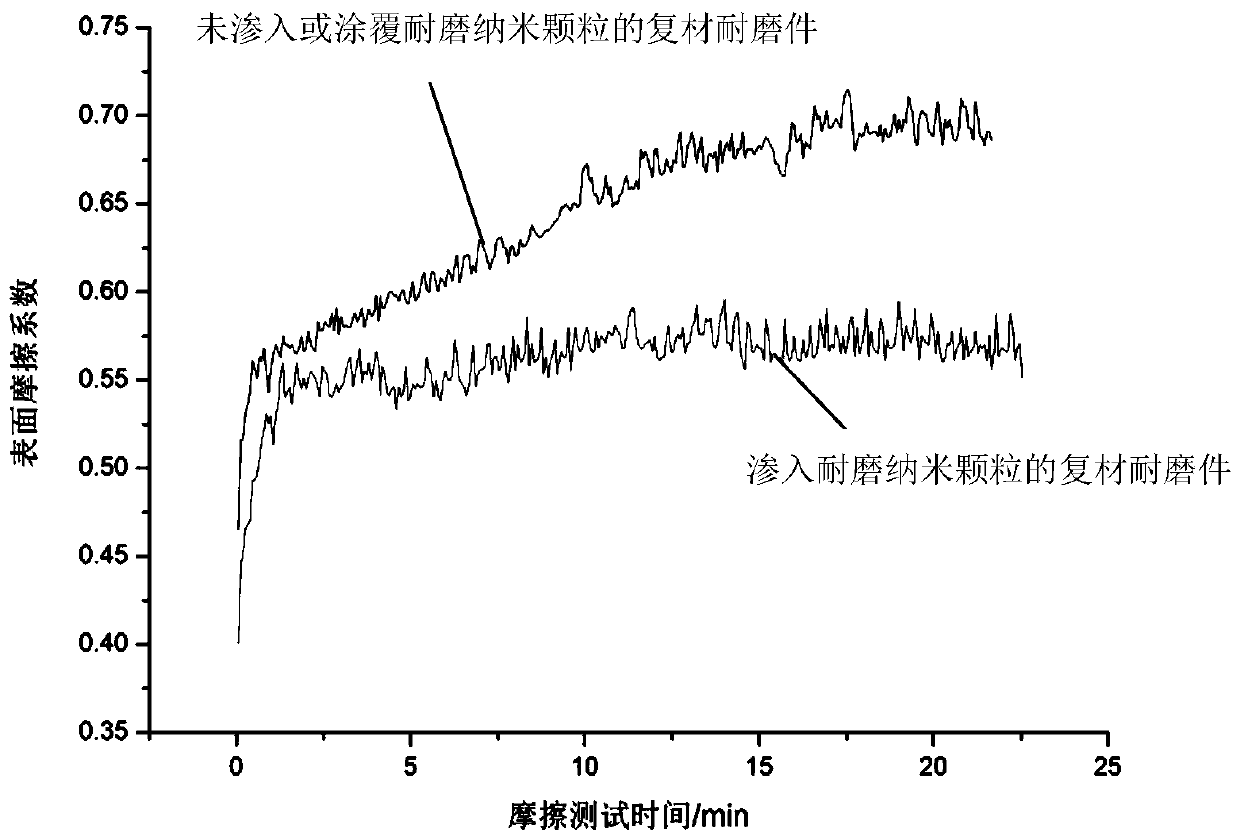

Embodiment 1

[0067] In this embodiment, the preparation of composite brake pads is taken as an example. Graphene nanoparticles are used to improve the wear resistance of fiber-reinforced cyanate ester composite materials, reduce the surface friction coefficient of brake pads, reduce wear, and prolong service life.

[0068] The concrete method of this embodiment is:

[0069] 1) Preparation of resin film dispersed with graphene nanoparticles. In parts by mass, 0.5 parts of graphene nanoparticles are added to 300 parts of the dimethyl phthalate resin system, wherein in the dimethyl phthalate resin system, the dimethyl phthalate resin and The mass ratio of acetone is 1:2. Mix and disperse under the high-speed mixer for 3 hours, then add 100 parts of N,N'-(4,4'-methylenediphenyl)bismaleimide, and ultrasonically disperse at room temperature for 30 minutes Stir for 2 hours.

[0070] The dispersed graphene nanoparticles and resin mixture were stirred at 180° C. for 12 hours, and the solvent was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com