Method for preparing and regenerating iron complex type carbon film gas diffusion electrode applied to electric Fenton system

A gas diffusion electrode and complexation technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. Low efficiency and other problems, to achieve the effect of good electroreduction regeneration performance, easy popularization and application, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

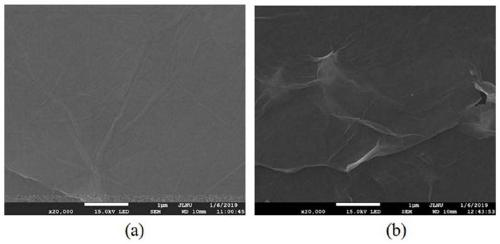

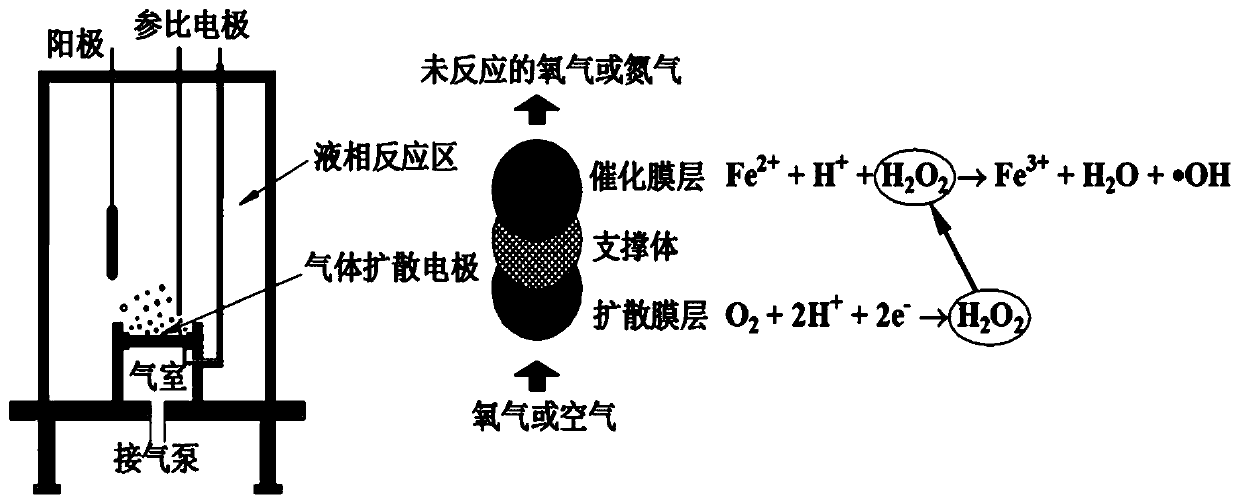

[0041] 1. Preparation method of gas diffusion electrode:

[0042] The chemical substance material used in the present invention is:

[0043] Nitrogen-doped graphitized carbon nanotubes: NCNT, purity>95%, outer diameter 10-30nm, length 5-15μm, nitrogen content 3.46wt%;

[0044] Graphene oxide dispersion: GO, the concentration is 4mg / mL;

[0045] Sodium hydroxide: NaOH, analytically pure;

[0046] Ferrous Sulfate Heptahydrate: FeSO 4 ·7H 2 O, analytically pure;

[0047] Polytetrafluoroethylene emulsion; PTFE, the concentration is 60wt%;

[0048] Absolute ethanol: C 2 h 6 O, analytically pure;

[0049] Acetone: CH 3 COCH 3 , analytically pure;

[0050] Deionized water: H2 O, resistivity ≥ 18MΩ;

[0051] Oxygen: O 2 , purity ≥ 99.999%;

[0052] Nitrogen: N 2 , purity ≥ 99.999%;

[0053] Anhydrous sodium sulfate: Na 2 SO 4 , analytically pure;

[0054] 4-Nitrophenol: C 6 h 5 NO 3 , analytically pure.

[0055] (1) Preparation of iron-complexed graphene oxide p...

Embodiment 2

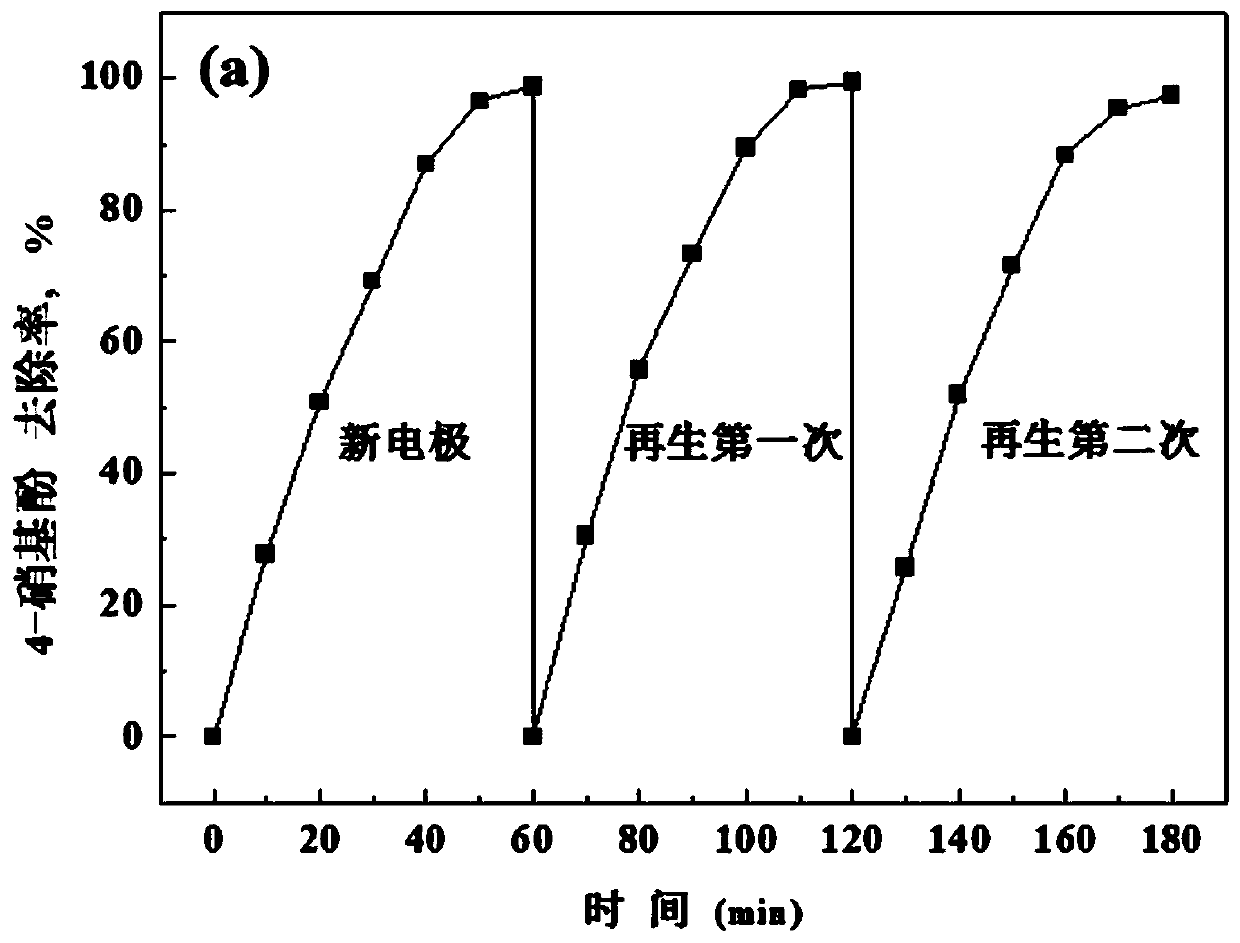

[0089] The preparation steps and dosage of iron-complexed graphene oxide powder and iron-complexed carbon film gas diffusion electrode are the same as in Example 1.

[0090] use figure 2 The bubbling electric Fenton reactor shown treats methylene blue simulated wastewater. The specific test conditions are as follows: the anode is a graphite electrode (50 × 40mm), and the cathode is an iron-complexed carbon film gas diffusion electrode (50mm in diameter); the reaction solution is a mixed solution of 400mL of 0.1mol / L sodium sulfate and 10mg / L methylene blue, The pH value is not adjusted; the gas used in the reaction is compressed air, and the flow rate of the gas is 100mL / min; at 5mA / cm 2 The solution can be completely decolorized when the current density is reacted for 90 minutes, and the TOC removal rate of the solution can reach 60.3% when reacted for 300 minutes, which can effectively treat organic wastewater.

[0091] Regeneration of iron-complexed carbon film gas diffu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com