Preparation method of alpha-cyanoacrylate

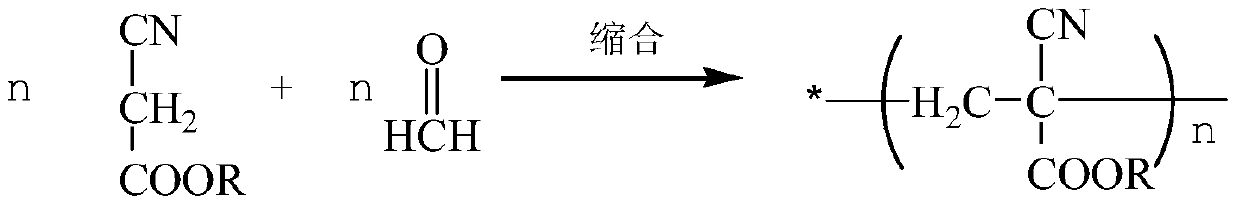

A technology of cyanoacrylate and cyanoacetate is applied in the field of preparation of α-cyanoacrylate and can solve the problems of low product yield and purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation method of α-ethyl cyanoacrylate monomer:

[0056] ①Mix 300g of ethyl cyanoacetate and solid formaldehyde or formaldehyde solution in dichloroethane or toluene medium, add hexahydropyridine catalyst, control the temperature at 70°C±5°C, and carry out condensation reaction for 2 hours to obtain α-cyanide Oligomers of ethyl acrylate;

[0057] Wherein the feeding amount of ethyl cyanoacetate and formaldehyde aqueous solution (calculated as formaldehyde) is 1.02:1.00, and the addition amount of hexahydropyridine is 0.15% of the weight percentage of ethyl cyanoacetate.

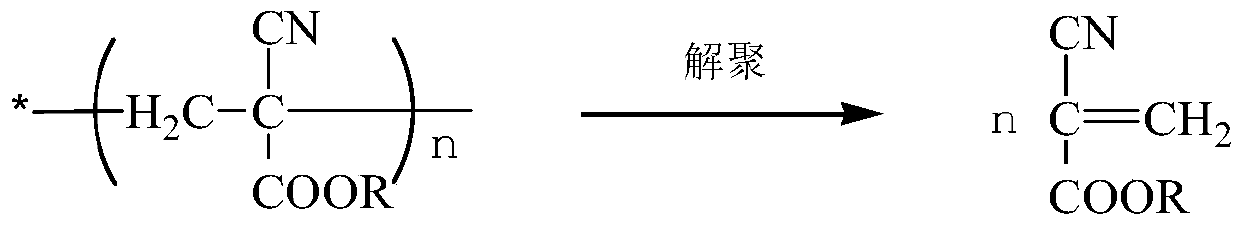

[0058] ②Add 50g of dioctyl phthalate to the oligomer of α-ethyl cyanoacrylate, remove the solvent under normal pressure or reduced pressure until the temperature of the kettle is 140°C, add 8g of phosphorus pentoxide, terephthalate Phenol 4g, cracked under reduced pressure at -0.098Mpa, collected fractions at 150-200°C, and obtained 290g of crude monomer of ethyl α-cyanoacrylate;

[0059] ③T...

Embodiment 2

[0062] The preparation method of n-butyl α-cyanoacrylate:

[0063] Get 500g of the α-ethyl cyanoacrylate monomer prepared in Example 1 and add in a 1000ml flask, add 1% chloroacetic acid, 0.3% hydroquinone and 0.33% concentrated sulfuric acid, add 444g n-butanol, stir Raise the temperature, control the temperature of the kettle to 100-115°C, collect the ethanol fraction at the top of the tower at 76-82°C; Pressure (200-800Pa) to collect fractions with a content > 98% until the temperature at the top of the column drops significantly. 425 g of n-butyl α-cyanoacrylate with a content >99% were obtained.

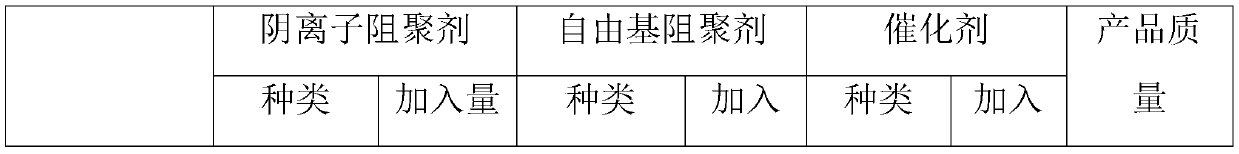

[0064] Among the present invention, select glacial acetic acid or anhydrous phosphoric acid as the anionic polymerization inhibitor, select methanesulfonic acid or p-toluenesulfonic acid to replace chloroacetic acid and the concentrated sulfuric acid in the present embodiment as the catalyst, as long as the consumption of the anionic polymerization inhibitor is 1-2% of the mol...

Embodiment 3

[0066] The preparation method of n-butyl α-cyanoacrylate:

[0067] Take 500 g of the α-ethyl cyanoacrylate monomer prepared in Example 1 and add it to a 1000 ml flask, add 2% of a mixture of glacial acetic acid and anhydrous phosphoric acid (the molar ratio of glacial acetic acid and anhydrous phosphoric acid is 0.7:1), The mixture of 0.35% hydroquinone and 0.45% concentrated sulfuric acid and p-toluenesulfonic acid (the mol ratio of concentrated sulfuric acid and p-toluenesulfonic acid is 1:1), add 444g n-butanol, stir and heat up, control the temperature of the kettle at 100 -115°C, collect the ethanol fraction at the top of the tower at 76-82°C; increase the temperature of the kettle to 120-140°C, collect n-butanol under normal pressure and water pump decompression (-0.1MPa), and depressurize the oil pump (200-800Pa) Fractions containing >98% were collected until the overhead temperature dropped significantly. 440 g of n-butyl α-cyanoacrylate with a content >99% was obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com