Perovskite nanosheet material as well as preparation method and application thereof

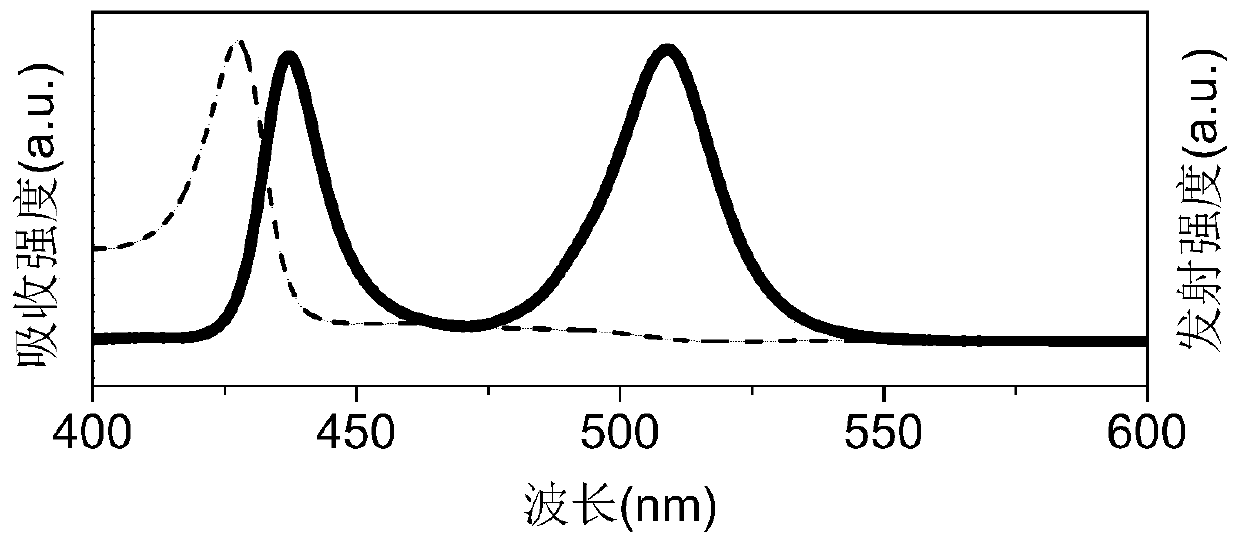

A technology of nanosheets and perovskites, applied in the field of materials, can solve the problems of non-uniform size of perovskite nanosheets and incomplete symmetry of luminescence peaks, and achieve the effects of easy control, uniform thickness, and great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Add 0.203g Cs to the mixture of 10mL octadecene and 0.625mL oleic acid 2 CO 3 , heated to 100°C under the protection of nitrogen, kept for 30min, and when Cs 2 CO 3 Dissolve completely, raise the temperature to 150°C, and keep it warm for 30 minutes to obtain the cesium oleate precursor; add 0.099g ferric bromide powder to the mixture of 5mL octadecene, 1.3mL oleic acid and 1.3mL oleylamine, at room temperature 400r / Stir until the ferric bromide powder is completely dissolved, then add 0.069g of lead bromide to the obtained mixed solution, raise the temperature to 100°C under the protection of nitrogen, keep it warm for 0.5h, and wait until the powder is completely dissolved to obtain a mixed solution of iron and lead;

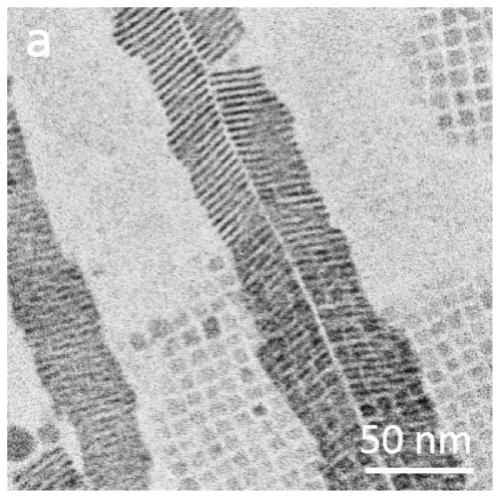

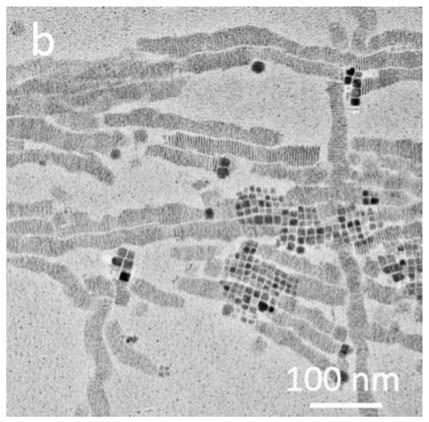

[0028] (2) Raise the temperature of the above-mentioned iron-lead mixture to 140°C, raise the temperature of the cesium oleate precursor to 100°C, take 0.4mL into the iron-lead mixture, keep it warm at 140°C for 5s, and then cool it in an ice-wat...

Embodiment 2

[0030] (1) Add 0.203g Cs to the mixture of 10mL octadecene and 0.625mL oleic acid 2 CO 3 , heated to 130°C under the protection of nitrogen, and kept for 30min, until Cs 2 CO 3 Dissolve completely, raise the temperature to 150°C, and keep it warm for 30 minutes to obtain the precursor of cesium oleate; add 0.055g ferric bromide powder to the mixture of 5mL octadecene, 0.9mL oleic acid and 0.9mL oleylamine, and heat at room temperature at 600r / Stir for 1 min until the iron bromide powder is completely dissolved, then add 0.069g of lead bromide to the obtained mixed solution, raise the temperature to 120°C under the protection of nitrogen, keep it warm for 0.5h, and wait until the powder is completely dissolved to obtain the iron-lead mixed solution;

[0031] (2) Raise the temperature of the above-mentioned iron-lead mixture to 140°C, raise the temperature of the cesium oleate precursor to 100°C, take 0.4mL into the iron-lead mixture, keep it warm at 140°C for 5s, and then co...

Embodiment 3

[0033] (1) Add 0.203g Cs to the mixture of 10mL octadecene and 0.625mL oleic acid 2 CO 3 , heated to 130°C under the protection of argon, and kept for 30min, until Cs 2 CO 3 Dissolve completely, raise the temperature to 150°C, and keep it warm for 30 minutes to obtain the cesium oleate precursor; add 0.099g ferric bromide powder to the mixture of 5mL octadecene, 1.3mL oleic acid and 1.3mL oleylamine, and heat it at room temperature at 600r / Stir until the ferric bromide powder is completely dissolved, then add 0.069g of lead bromide to the obtained mixed solution, raise the temperature to 100°C under the protection of argon, keep it warm for 0.5h, and wait until the powder is completely dissolved to obtain a mixed solution of iron and lead;

[0034] (2) Raise the temperature of the above-mentioned iron-lead mixture to 130°C, raise the temperature of the cesium oleate precursor to 100°C, take 0.4mL into the iron-lead mixture, keep it warm at 130°C for 5min, and then bathe in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com