Non-refrigeration infrared focal plane of compound absorption film layer and preparation method thereof

An uncooled infrared, absorbing film technology, applied in electrical radiation detectors and other directions, can solve the problems of reduced performance, increased equivalent heat capacity, increased thickness of the absorbing layer, etc., to achieve performance, increase process complexity, The effect is favorable for large-scale low-cost preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

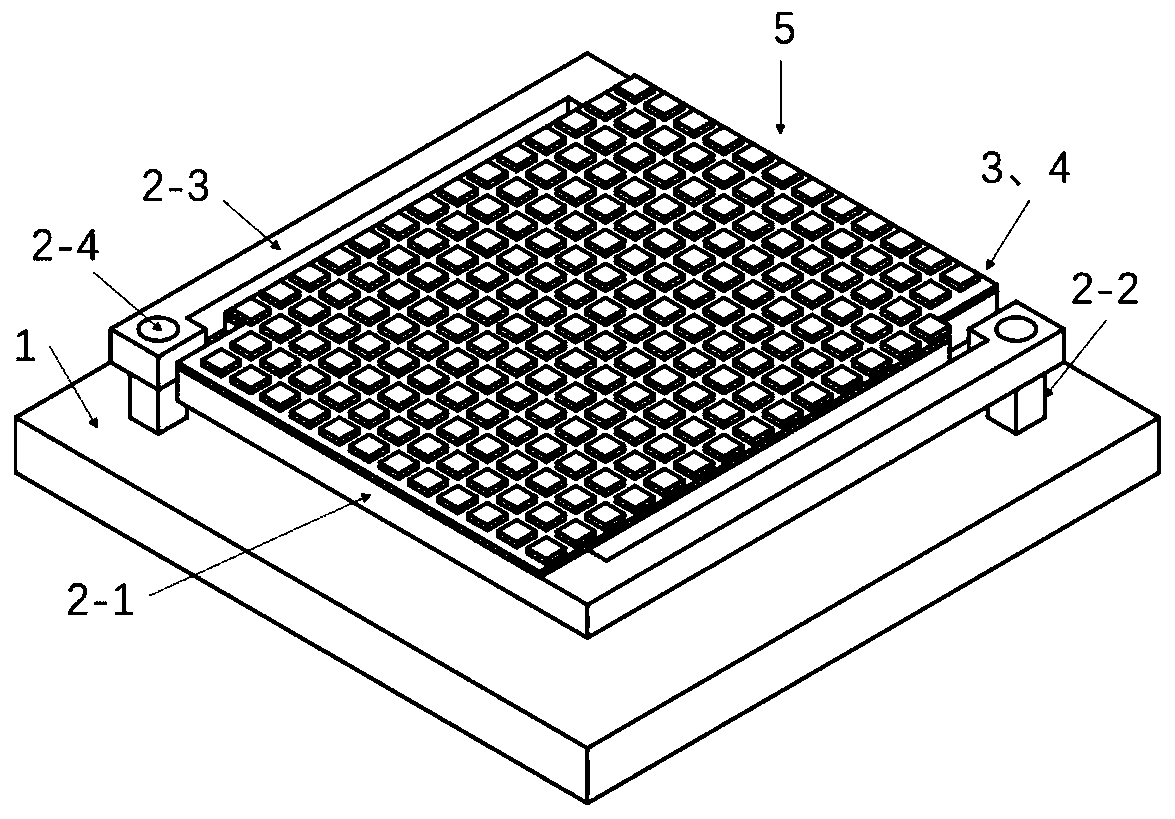

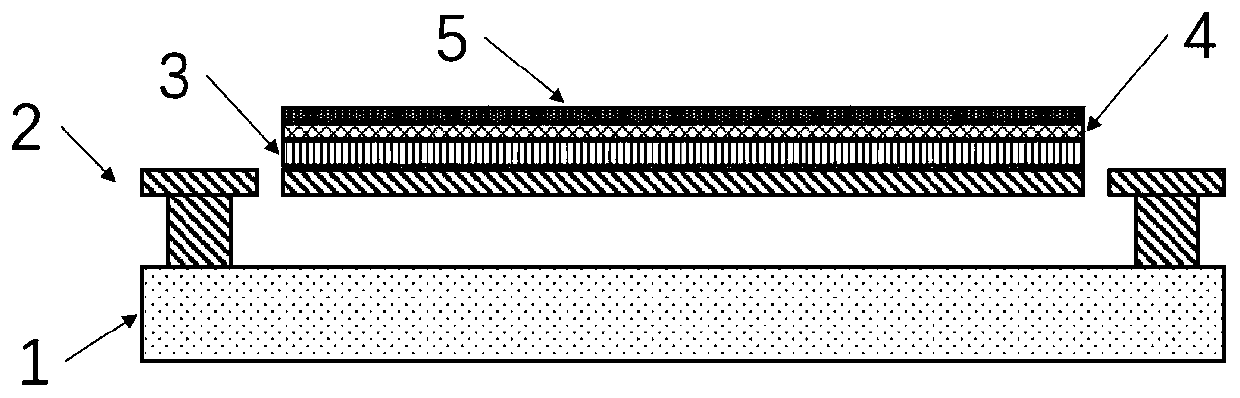

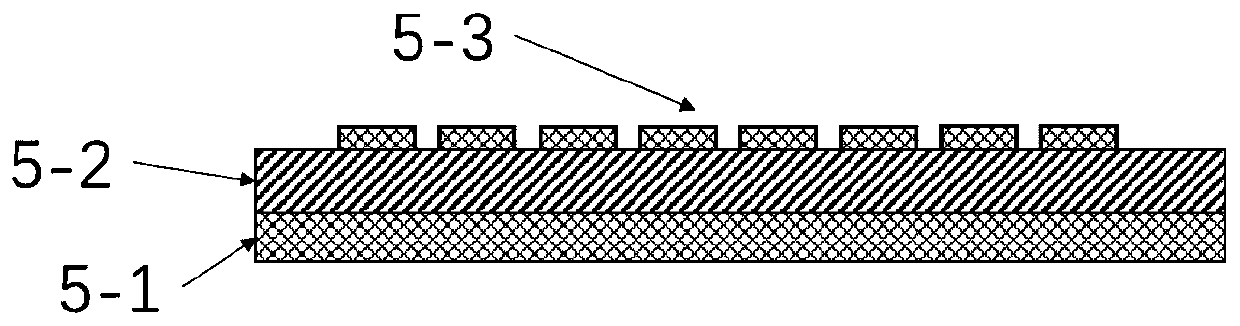

[0050] An uncooled infrared focal plane of a composite absorbing film such as figure 1 shown. The focal plane pixel unit metal microarray structure is as follows Figure 4 As shown, the first dielectric layer 5-2-1 is made of germanium (Ge), the metal microarray 5-3 is made of gold (Au), and each metal unit is a super-pixel with a square structure 5-3-1. The side length of the square structure 5-3-1 is 1 μm. The infrared radiation with a wavelength near 8 microns is captured by the composite absorbing film layer 5, and converts the light energy into Joule heat of the metal structure and phonon absorption of the dielectric structure, and then heats the thermistor layer 3, thereby turning the measured The temperature change of the composite absorbing film layer 5 caused by the infrared radiation signal is converted into an electrical signal, and the infrared information of the target is obtained through the readout circuit 1 to realize infrared detection and imaging.

[0051]...

Embodiment 2

[0062] An uncooled infrared focal plane structure of a composite absorbing film such as figure 1 shown. The focal plane pixel unit metal microarray structure is as follows Figure 5 As shown, the second dielectric layer 5-2-2 is made of silicon (Si), the metal microarray 5-3 is made of gold (Au), each metal unit is a cross-shaped structure 5-3-2, and the length of the long side is 2 microns , the short side length is 1 micron, and the infrared radiation with a wavelength of 9 microns is captured by the composite absorbing film layer 5, and the light energy is converted into Joule heat of the metal structure and phonon absorption of the dielectric structure, and then the thermistor layer 3 is heating, thereby converting the temperature change of the composite absorbing film layer 5 caused by the measured infrared radiation signal into an electrical signal, and then obtaining the infrared information of the target through the readout circuit 1 to realize infrared detection and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com