Boron-containing organosilicone tackifier in linear structure and preparation method thereof

A linear structure, silicone technology, applied in the direction of polymer adhesive additives, adhesive additives, etc., can solve the problems of silicone tackifier influence, unfavorable diffusion, difficult to remove, etc., to improve adhesive performance and repeatability and controllability, the effect of improving the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

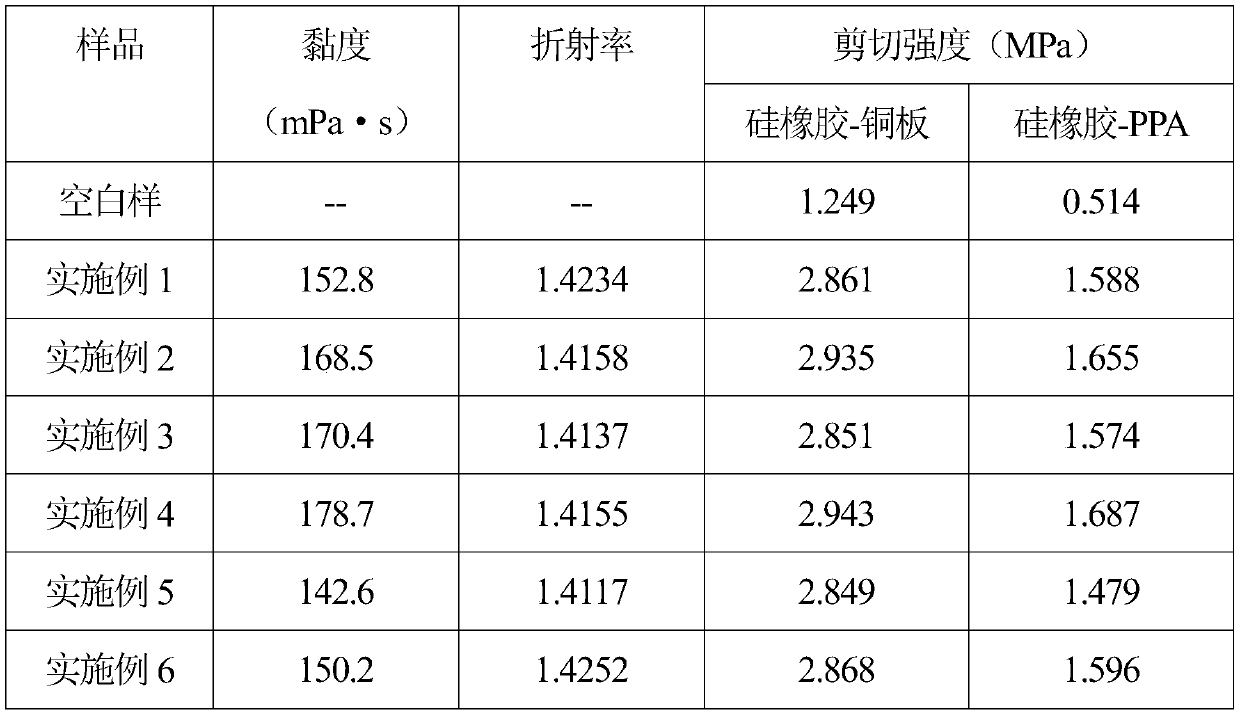

Embodiment 1

[0025] This embodiment provides a boron-containing silicone tackifier with a linear structure and a preparation method thereof.

[0026] Take 6.18g of boric acid powder and dissolve it in ethanol, mix it with 22.03g of γ-glycidyl etheroxypropylmethyldimethoxysilane and 13.22g of vinylmethyldimethoxysilane, and add it to a tank equipped with magnetic stirring and temperature control. In a 250ml three-necked flask of a device, a basic anion exchange resin accounting for 1% of the total reactant mass fraction was added and reacted at 95° C. for 4 h. After the reaction, filter the product under reduced pressure to remove the basic anion exchange resin, then transfer the filtrate to a round-bottomed distillation flask, and remove by-products in the system at 100°C and -0.096MPa to obtain an orange transparent A boron-containing silicone adhesion promoter with a linear structure.

Embodiment 2

[0028] This embodiment provides a boron-containing silicone tackifier with a linear structure and a preparation method thereof.

[0029] Take 6.18g of boric acid powder and dissolve it in ethanol, mix it with 44.06g of γ-glycidyl etheroxypropylmethyldimethoxysilane and 26.44g of vinylmethyldimethoxysilane, and add it to a tank equipped with magnetic stirring and temperature control. In a 250ml three-necked flask of a device, a basic anion exchange resin accounting for 1% of the total reactant mass fraction was added and reacted at 95° C. for 4 h. After the reaction, filter the product under reduced pressure to remove the basic anion exchange resin, then transfer the filtrate to a round-bottomed distillation flask, and remove by-products in the system at 100°C and -0.096MPa to obtain an orange transparent A boron-containing silicone adhesion promoter with a linear structure.

Embodiment 3

[0031] This embodiment provides a boron-containing silicone tackifier with a linear structure and a preparation method thereof.

[0032] Take 6.18g of boric acid powder and dissolve it in ethanol, mix it with 22.03g of γ-glycidyl etheroxypropylmethyldimethoxysilane and 16.03g of vinylmethyldiethoxysilane, and add it to a tank equipped with magnetic stirring and temperature control. In a 250ml three-necked flask of a device, a basic anion exchange resin accounting for 1% of the total reactant mass fraction was added and reacted at 95° C. for 4 h. After the reaction, filter the product under reduced pressure to remove the basic anion exchange resin, then transfer the filtrate to a round-bottomed distillation flask, and remove by-products in the system at 100°C and -0.096MPa to obtain an orange transparent A boron-containing silicone adhesion promoter with a linear structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com