A kind of modified rubber seal and preparation method thereof

A technology of modified rubber and seals, which is applied in the field of modified rubber, which can solve the problems of easily deformed rubber gasket sealing performance, reduce the sealing performance of rubber gasket, and easy aging of rubber gasket, and achieve wear-resistant processing and water absorption. The effect of low rate and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

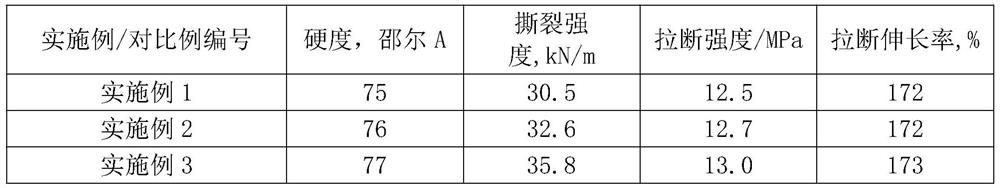

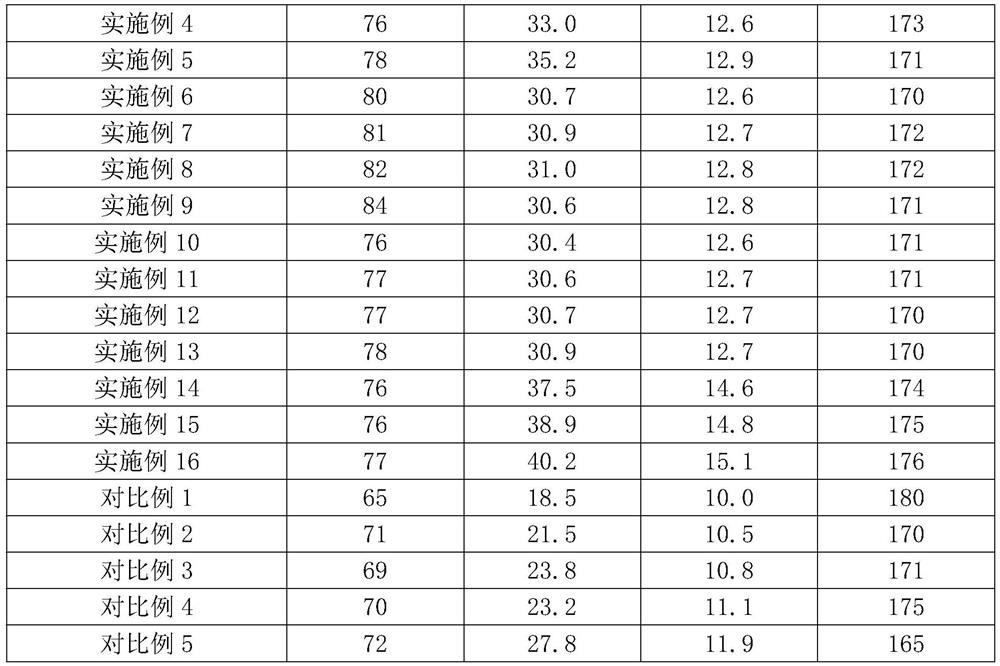

Examples

Embodiment 1

[0044] Example 1: A modified rubber seal, the components and their corresponding parts by mass are shown in Table 1, and are prepared through the following steps:

[0045] Step 1: Put styrene-butadiene rubber and EPDM rubber into the internal mixer for internal mixing, then add zinc oxide, stearic acid, accelerator, silicon dioxide, carbon fiber tube, and modified aramid fiber, and then internally mix , to get the rubber compound;

[0046] Step 2, putting the mixed rubber into an open mill for open milling, adding sulfur after standing for 5 hours, and performing open milling again to obtain rubber compound;

[0047] Step 3: Put the rubber material into the mold of the vulcanizing machine for vulcanization. The vulcanization temperature is 160° C. and the vulcanization time is 30 minutes. After the vulcanization is completed, cool to room temperature and demould to obtain the modified rubber seal.

[0048] Among them, the preparation method of the modified aramid fiber is as ...

Embodiment 2-9

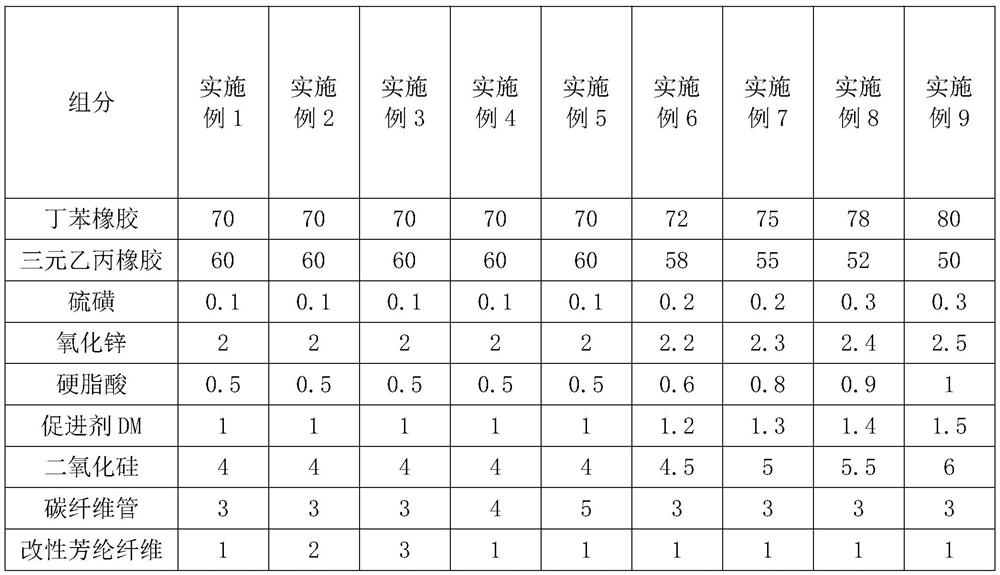

[0049] Example 2-9: A modified rubber seal, the difference from Example 1 is that the components and their corresponding parts by mass are shown in Table 1.

[0050] Each component and its mass parts in table 1 embodiment 1-9

[0051]

Embodiment 10

[0052]Embodiment 10: A modified rubber seal. The difference from Example 1 is that the preparation method of the modified aramid fiber is as follows: 100mL of acetone solution is put into the container, and then the aramid fiber, benzophenone Put glycidyl methacrylate into an acetone solution, carry out grafting reaction under the radiation of ultraviolet light after purging nitrogen to remove oxygen, and the radiation time is 13min. After the reaction is completed, filter, wash and dry to obtain modified aramid fiber; The mass ratio of glycidyl methacrylate to acetone solution is 4%; the mass ratio of benzophenone to acetone solution is 1.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com