Polyesterimide/bismaleimide resin composite material and preparation method

A technology of bismaleimide resin and maleimide resin, which is applied in the field of composite materials, can solve the problems of unfavorable comprehensive performance resin materials, and achieve excellent self-reinforcement and toughening, good heat resistance, and easy processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

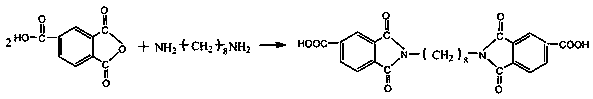

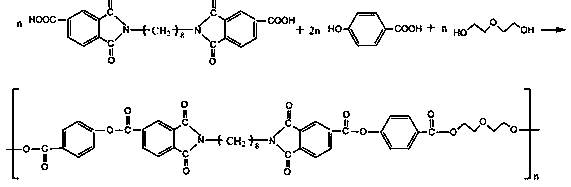

Method used

Image

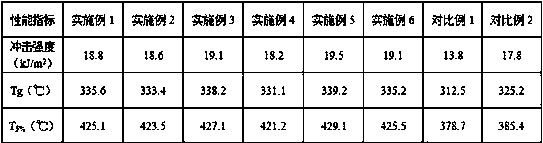

Examples

Embodiment 1

[0027] (1) Preparation of polyester-imide thermotropic liquid crystal: add octanediamine and trimellitic anhydride to N,N-dimethylformamide, stir until completely dissolved, then heat to 153°C and reflux for 170 minutes, then cool in ice water , Filter to obtain N,N'-1,8-octylene-bismellitic acid imide diacid, and then N,N'-1,8-octylene-bismellitic acid imide Add amine diacid, p-hydroxybenzoic acid, and diethylene glycol ether to N,N-dimethylformamide, place it in an oil bath at 86°C and stir for 14 minutes, then add dibutyltin dilaurate, and continue heating to 113°C React for 3.5h, filter, wash, and dry after the reaction to prepare thermotropic liquid crystal polyesterimide; in preparation of N,N'-1,8-octylene-bisphthalimide diacid , The parts by weight of each raw material are 14 parts by weight of octanediamine, 19 parts by weight of trimellitic anhydride, and 67 parts by weight of N,N-dimethylformamide; in the preparation of the thermotropic liquid crystal polyester imide...

Embodiment 2

[0031] (1) Preparation of polyester-imide thermotropic liquid crystal: add octanediamine and trimellitic anhydride to N,N-dimethylformamide, stir until completely dissolved, then heat to 151°C and reflux for 170 minutes, then cool in ice water , Filter to obtain N,N'-1,8-octylene-bismellitic acid imide diacid, and then N,N'-1,8-octylene-bismellitic acid imide Add amine diacid, p-hydroxybenzoic acid, and diethylene glycol ether to N,N-dimethylformamide, place it in an oil bath at 82°C and stir for 18 minutes, then add dibutyltin dilaurate, and continue at 111°C React for 4h, filter, wash, and dry after the reaction to prepare thermotropic liquid crystal polyesterimide; in the preparation of N,N'-1,8-octylene-bistrimellitic acid imide diacid, The parts by weight of each raw material are: 13.5 parts by weight of octanediamine, 19 parts by weight of trimellitic anhydride, and 67.5 parts by weight of N,N-dimethylformamide; in the preparation of thermotropic liquid crystal polyester ...

Embodiment 3

[0035] (1) Preparation of polyester-imide thermotropic liquid crystal: Add octanediamine and trimellitic anhydride to N,N-dimethylformamide, stir until completely dissolved, then heat to 154°C and reflux for 160min, then cool in ice water , Filter to obtain N,N'-1,8-octylene-bismellitic acid imide diacid, and then N,N'-1,8-octylene-bismellitic acid imide Add amine diacid, p-hydroxybenzoic acid, and diethylene glycol ether to N,N-dimethylformamide, place it in an oil bath at 88°C and stir for 12 minutes, then add dibutyltin dilaurate, and continue at 114°C React for 3h, filter, wash and dry after the reaction to prepare thermotropic liquid crystal polyesterimide; in the preparation of N,N'-1,8-octylene-bistrimellimidic acid, The parts by weight of each raw material are 14 parts by weight of octanediamine, 21 parts by weight of trimellitic anhydride, and 65 parts by weight of N,N-dimethylformamide; in the preparation of the thermotropic liquid crystal polyesterimide, the parts by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com