Preparation method of D-type plastic optical fiber based on graphene gold film and application of preparation method in an SPR biosensor

A technology of plastic optical fiber and olefinic gold film, which is applied in the application field of SPR biosensors, can solve the problems of reducing the detection sensitivity and the low sensitivity of the optical fiber of the SPR sensor, etc., and achieve the effects of enhancing detection sensitivity, improving detection sensitivity, and increasing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

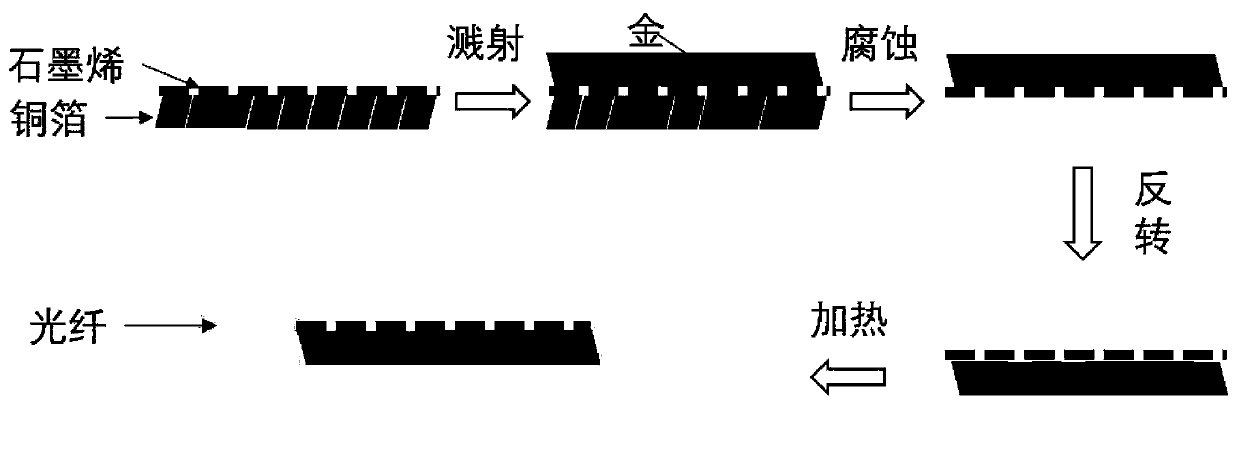

[0054] The invention provides a kind of preparation method based on the D-type plastic optical fiber of graphene gold film, comprises the following steps:

[0055] (1) Select a section of the plastic optical fiber as the sensing area, the plastic optical fiber includes a core and a cortex wrapping the core, and removes a part of the cortex and the core of the sensing area along the axial direction of the sensing fiber to obtain a D-shaped structure; The section of the D-shaped structure perpendicular to the axial direction of the plastic optical fiber is D-shaped, and the D-shaped structure forms a cut surface along the optical fiber axis;

[0056] (2) grow a graphene layer on one side of the copper foil to obtain a copper foil / graphene material;

[0057] (3) coating gold film layer on the graphene surface of copper foil / graphene material, obtains copper foil / graphene / gold material;

[0058] (4) Soak copper foil / graphene / gold material in ferric chloride solution to obtain gra...

Embodiment 1

[0081] Cut the plastic optical fiber into 15 cm long slices, the plastic optical fiber includes a core and a cortex wrapping the core. Select the length of 1cm as the sensing area, and remove part of the core and skin of the sensing area by side polishing along the axial direction of the plastic optical fiber to form a D-shaped structure. The interface between the D-shaped structure and the axial direction of the plastic optical fiber is D-shaped. Side polishing removes part of the surface of the core and skin to form a cut surface. The D-form structure was then rinsed with deionized water to remove impurities.

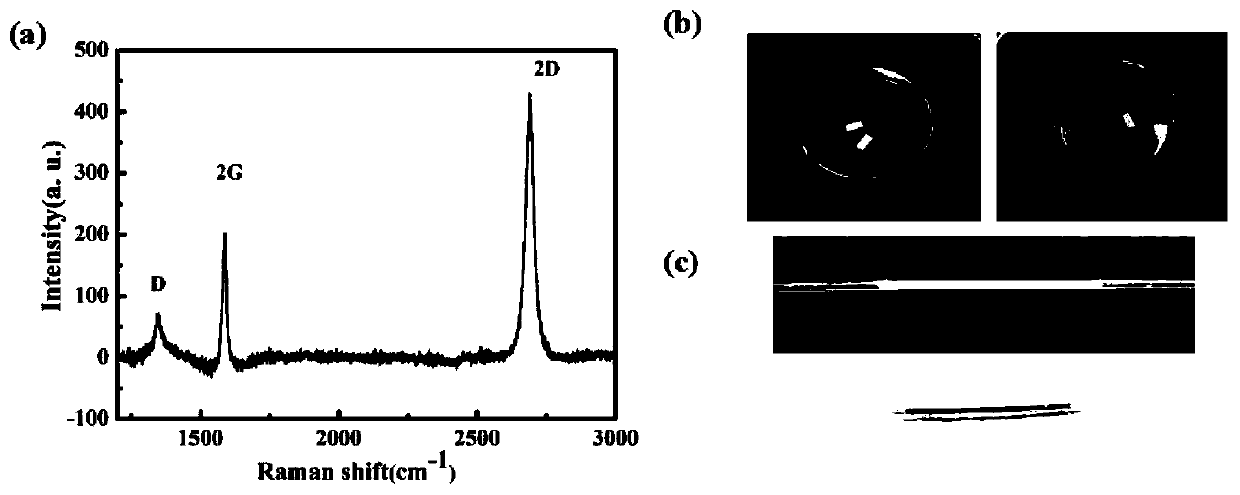

[0082] Grow single-layer graphene on high-purity copper foil, and cut the copper foil / graphene into 1.5cm*0.5cm rectangular strips. A 50nm-thick gold film is formed on the graphene surface of the cut copper foil / graphene by sputtering technology to obtain a copper foil / graphene / gold material. The thickness of the gold film deposited on the graphene / copper film can b...

Embodiment 2

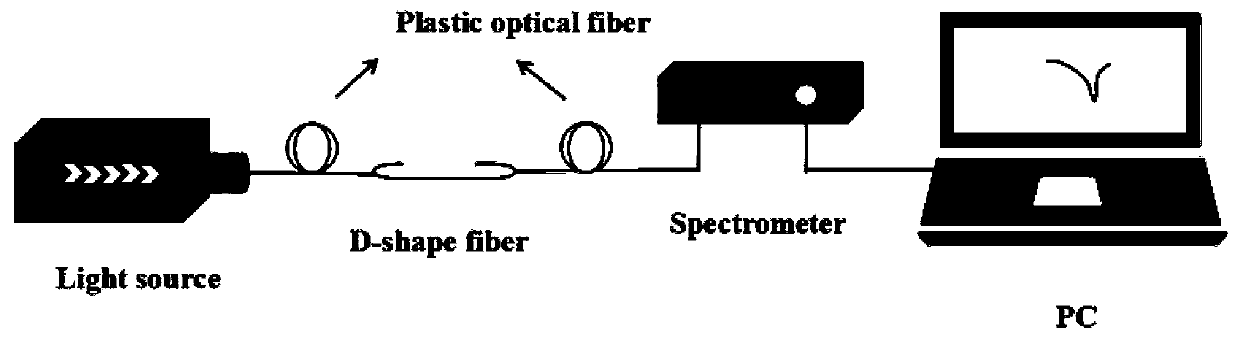

[0092] This embodiment detects the sensitivity of the D-type sensing fiber

[0093] The SRP sensor includes: a focused light source, a transmission fiber, the D-type sensing fiber prepared in Example 1 or Comparative Example 1, a spectrometer and a computer, wherein the focused light source and the D-type sensing fiber are connected through the transmission fiber, and the D-type sensing fiber and the spectrometer The spectrometer is connected to the computer through the transmission fiber connection, and the data is collected and output through the Morpho software in the computer. That is, the Au D-type SPR sensor and the G / Au D-type SPR sensor are obtained.

[0094] In the present invention, the D-type sensing optical fibers prepared in Comparative Example 1 and Example 1 are soaked in deionized water (1.333) and ethanol solutions with mass concentrations of 10%, 20%, 30% and 50% (refractive index ( RI) between 1.339~1.3583), utilize above-mentioned SPR sensor to measure the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com