Method for dissolving corn starch and method for detecting turning radius and molecular weight distribution of corn starch

A technology of molecular weight distribution and corn starch, applied in the field of detecting the radius of gyration and molecular weight distribution of corn starch, and dissolving corn starch, can solve the problems of improved molecular weight distribution detection accuracy, harsh dissolution conditions, long dissolution time, etc., to solve the problem of long dissolution time , Short dissolution time, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Accurately weigh 20 mg of cornstarch into a 20 mL sample bottle, add 40 μL of 80% ethanol to wet the starch, tighten the screw cap of the sample bottle, and stir magnetically at 200 rpm for 5 min at room temperature. Add 2.0 mL DMSO dropwise to the vial, and continue magnetic stirring at 200 rpm for 30 min at room temperature. Afterwards, the samples were subjected to ultrasonic treatment for 2.5 min, in which the ultrasonic frequency was 40KHz and the ultrasonic power was 80 W. Finally, magnetic stirring at 160 rpm in a boiling water bath at 100 °C for 30 min can obtain a completely dissolved cornstarch solution.

[0048] This method is compared with the method of Comparative Example 1, and the results are shown in Table 2:

[0049] Table 2 Comparison table of corn starch dissolution methods

[0050]

Embodiment 2

[0052] Accurately weigh 20 mg of cornstarch into a 20 mL sample bottle, add 30 μL of 80% ethanol to wet the starch, tighten the screw cap of the sample bottle, and stir magnetically at 200 rpm for 5 min at room temperature. Add 2.0 mL DMSO dropwise to the vial, and continue magnetic stirring at 200 rpm for 30 min at room temperature. Afterwards, the samples were subjected to ultrasonic treatment for 2.5 min, in which the ultrasonic frequency was 40KHz and the ultrasonic power was 80 W. Finally, magnetically stir at 160 rpm for 30 min in a boiling water bath at 100 °C.

Embodiment 3

[0054] Accurately weigh 20 mg of cornstarch into a 20 mL sample bottle, add 50 μL of 80% ethanol to wet the starch, tighten the screw cap of the sample bottle, and stir magnetically at 200 rpm for 5 min at room temperature. Add 2.0 mL DMSO dropwise to the vial, and continue magnetic stirring at 200 rpm for 30 min at room temperature. Afterwards, the samples were subjected to ultrasonic treatment for 2.5 min, in which the ultrasonic frequency was 40KHz and the ultrasonic power was 80 W. Finally, magnetically stir at 160 rpm for 30 min in a boiling water bath at 100 °C.

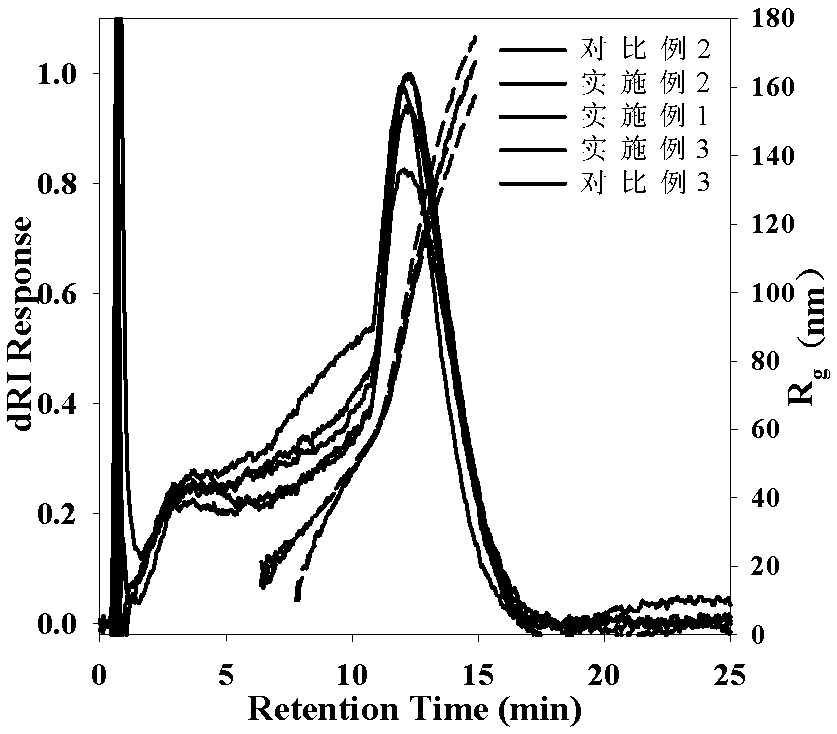

[0055] The starch that adopts embodiment 1~3 and comparative example 2~3 method gain is tested, and result is as follows Figure 3~4 shown. As can be seen from the figure, the AF4-MALS-dRI elution peak signal of the sample obtained by the method of Comparative Example 2 is low, indicating that the corn starch may not be completely dissolved; the AF4-MALS-dRI elution peak of the sample obtained by the method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com