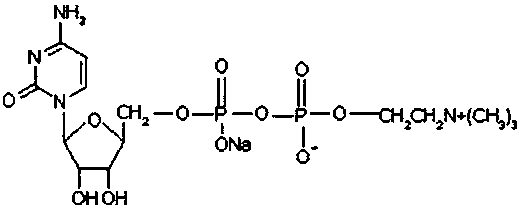

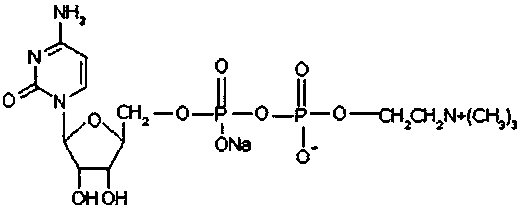

Method for separating and purifying citicoline sodium from microbial fermentation liquor

A technology for sodium citicoline and microbial fermentation liquid, which is applied in the field of separation and purification of sodium citicoline to achieve the effects of improving separation efficiency and product yield, reducing waste water volume and prolonging service cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

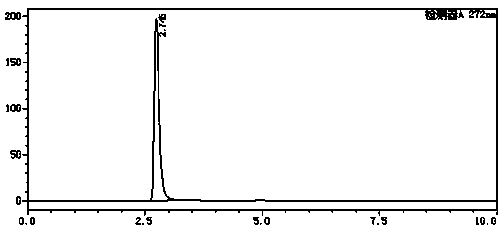

Examples

Embodiment 1

[0032] According to the method above, 8.4 L of CDP-choline fermentation broth was prepared, in which the concentration of CDP-choline was 19.5 g / L, totaling 163.8 g. The treatment process is as follows:

[0033] 1) 8.4L citicoline fermentation broth was heated at 100°C for 30min, and 0.2% acid-soluble chitosan was added for flocculation, resulting in a flocculent precipitate, which was filtered through a plate and frame filter to obtain a clear liquid, which was collected and passed through by ultrafiltration liquid, and the permeate was collected by nanofiltration to obtain the final pretreatment liquid. Among them: the ultrafiltration membrane and the nanofiltration membrane are all made of polyethersulfone; the molecular weight cut-off of the ultrafiltration membrane is 10,000 Daltons, the working pressure of the ultrafiltration is 0.7-0.9MPa, and the working temperature is 30-35°C; the molecular weight cut-off of the nanofiltration membrane It is 500 Daltons, the working ...

Embodiment 2

[0038] According to the above method, 8.0 L of CDP-choline fermentation broth was prepared, in which the concentration of CDP-choline was 21.3 g / L, totaling 170.4 g. The treatment process is as follows:

[0039] 1) 8.0L citicoline fermentation liquid was heated at 80°C for 45 minutes, and 0.15% acid-soluble chitosan was added for flocculation, resulting in flocculent precipitates, which were centrifuged to obtain the clear liquid, and the clear liquid was collected by ultrafiltration to collect the permeate, and passed through The retentate was collected by nanofiltration to obtain the final pretreatment solution. Among them: the ultrafiltration membrane and the nanofiltration membrane are all made of polyethersulfone; the ultrafiltration membrane molecular weight cut-off is 5000 Daltons, the ultrafiltration working pressure is 0.9-1.1MPa, and the working temperature is 35-40°C; the nanofiltration membrane molecular weight cut-off It is 200 Daltons, the working pressure of na...

Embodiment 3

[0044] According to the above method, 9.3 L of CDP-choline fermentation broth was prepared, in which the concentration of CDP-choline was 23.4 g / L, totaling 217.6 g. The treatment process is as follows:

[0045] 1) 9.3L citicoline fermentation broth was heated at 90°C for 40 minutes, and 0.1% acid-soluble chitosan was added for flocculation, resulting in a flocculent precipitate, which was filtered through a plate and frame filter to obtain a clear liquid, which was collected through ultrafiltration liquid, and the permeate was collected by nanofiltration to obtain the final pretreatment liquid. Among them: the ultrafiltration membrane and the nanofiltration membrane are all made of polyethersulfone; the ultrafiltration membrane molecular weight cut-off is 2000 Daltons, the ultrafiltration working pressure is 1.0-1.2 MPa, and the working temperature is 40-45°C; the nanofiltration membrane molecular weight cut-off It is 200 Daltons, the working pressure of nanofiltration is 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com