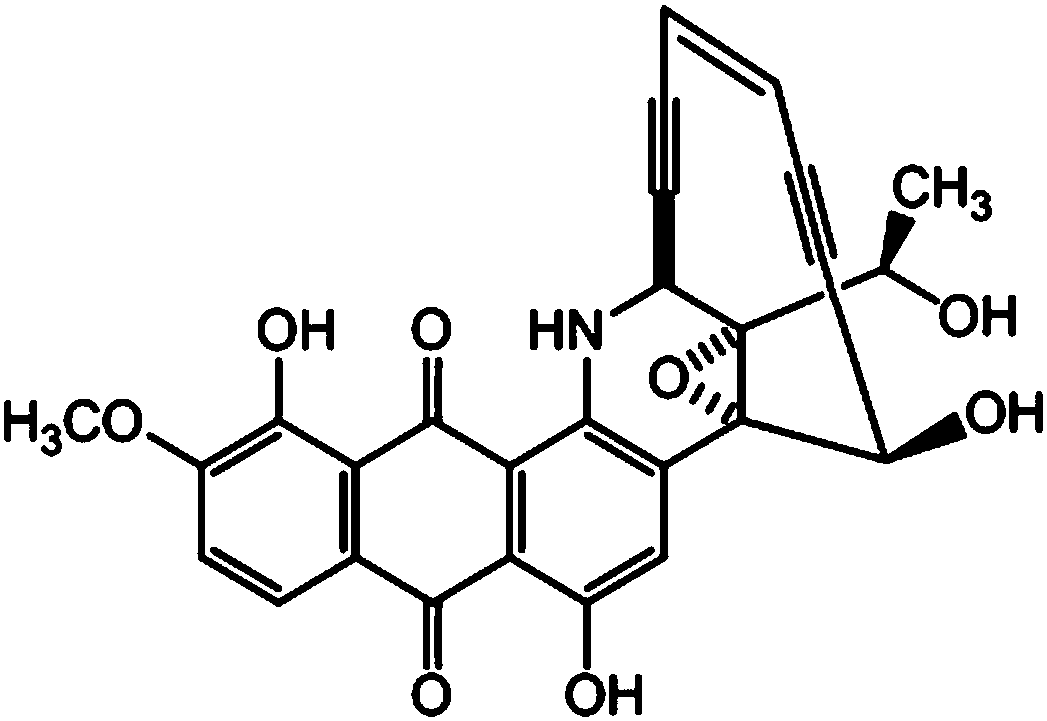

Fermentation process for preparing tiancimycin-A and derivatives thereof by streptomyces sp

A fermentation process, the technology of Tiancimycin, which is applied in the field of biomedicine, can solve the problems of many steps and large consumption of organic solvents, and achieve the effect of high-end drug prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

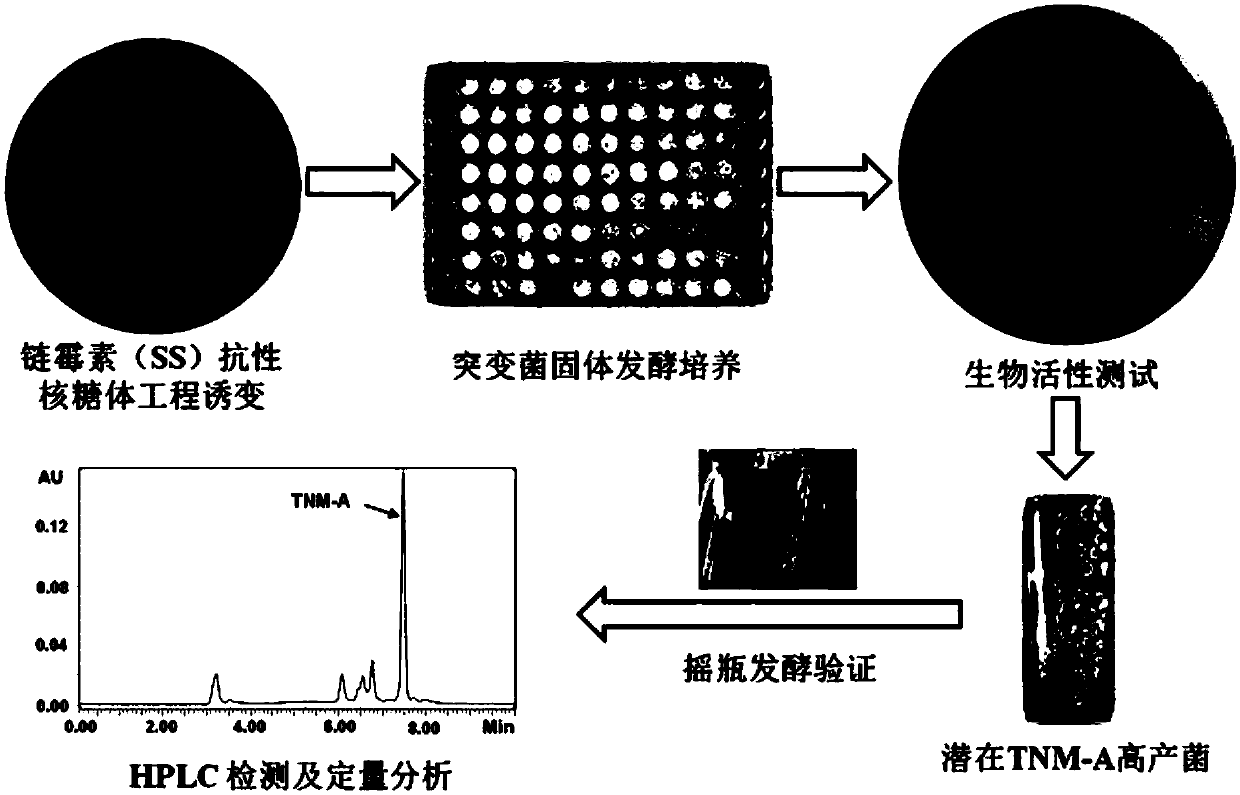

[0056] Example 1: Cultivation and fermentation of Streptomyces CB03234 and detection of biological activity of TNM-A

[0057] Streptomyces CB03234 was inoculated to Gaoshi No. 1 (G1) solid medium (the G1 solid medium was: 10g / L soluble starch, 0.5g / LMgSO 4 ·7H 2 O, 0.5g / LK 2 HPO 4 , 1g / L NaCl, 1g / L KNO 3 , 0.01g / L FeSO 4 ·7H 2 (0, 20g / L agar, pH=7.0) slant, cultivate about 8-15 days under 30 ℃ of constant temperature conditions, collect spores with aseptic 20% glycerin solution and obtain spore suspension and refrigerate in-80 ℃ for subsequent use. In order to obtain the target product TNM-A, 50 μ LCB03234 spore suspension was inoculated into 50 mL tryptone soybean broth (TSB) seed medium (the TSB seed medium was: 17 g / L tryptone, 3 g / L plant peptone, 2.5 g / L K 2 HPO 4 , 5g / L NaCl, 2.5g / L glucose, pH=7.3), after culturing for 48 hours at 30°C and 200rpm, 5mL seeds were transferred to 50mL production medium (the production medium was: 10g / L soluble starch, 5g / L cott...

Embodiment 2

[0058] Embodiment 2: Separation and purification and HPLC detection of TNM-A

[0059] The 50mL fermented liquid obtained in Example 1 is centrifuged and the supernatant and thalline are collected respectively, and the supernatant is extracted with ethyl acetate (EA) (50mL*3 times); the thalline is extracted with 50mL acetone, and the extract is passed through Concentrate on a rotary evaporator and then extract with EA water mixed solvent (1:1, volume ratio) (50mL*3 times), combine the above extraction phases, concentrate and dry again, and finally redissolve in methanol for HPLC detection. HPLC analysis conditions and procedures are as follows: mobile phase A is 99.9% deionized water and 0.1% formic acid; mobile phase B is 99.9% methanol and 0.1% formic acid, flow rate is 1.0mL / min, UV detector wavelength is 540nm, linear gradient analysis The program was: 0-5 minutes, 90% A to 5% A; 5-9 minutes, 5% A; 9-13 minutes, 5% A to 90% A; 13-15 minutes, 90% A.

Embodiment 3

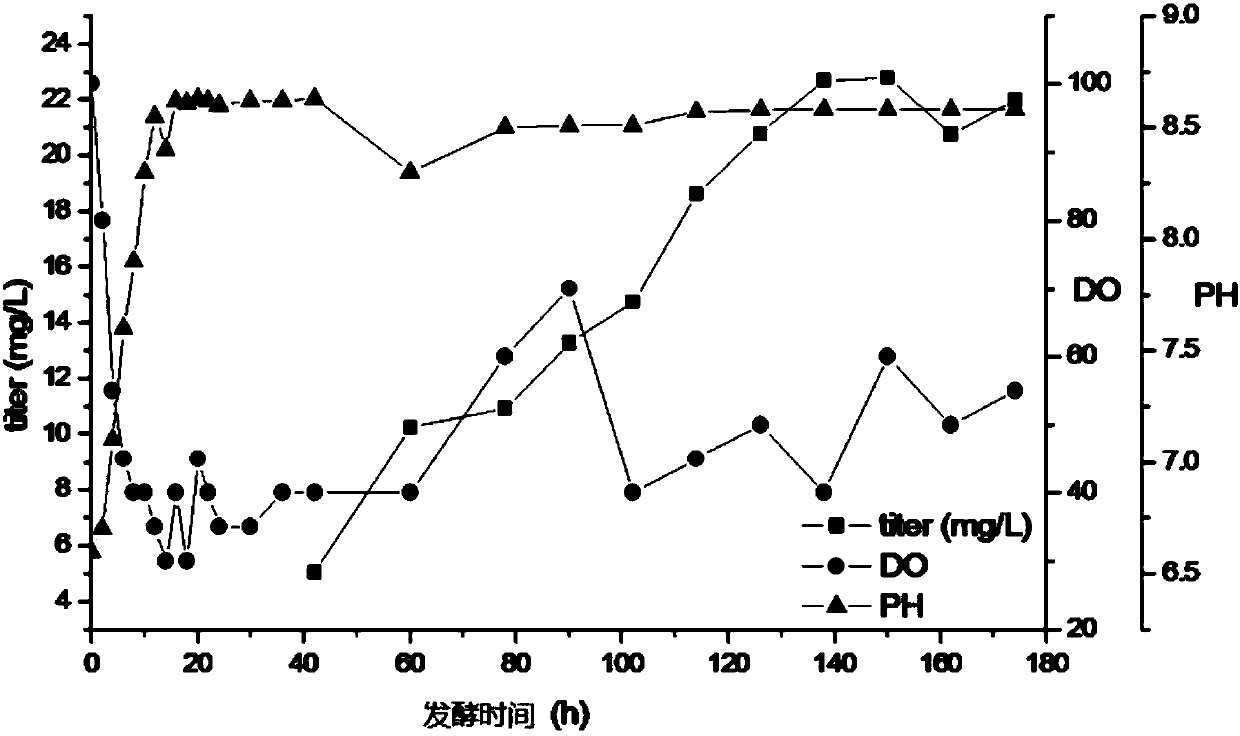

[0060] Embodiment 3: the addition of different types of resins in the fermentation process of Streptomyces CB03234

[0061] TNM-A is extremely toxic, and as its concentration increases in the later stage of fermentation, it will rapidly cause the death and autolysis of the bacteria that produce it, causing the pH value of the fermentation broth to rise sharply; while TNM-A will increase its concentration when the pH exceeds 7.5 Under certain conditions, it begins to decompose, and with the further increase of pH value, it accelerates the decomposition until it disappears. Therefore, adding macroporous resin to adsorb TNM-A during the fermentation process can effectively eliminate the toxic and side effects of TNM-A on its own strains to maintain stable biomass for TNM-A synthesis, and by reducing TNM-A in the fermentation broth concentration to further induce its synthesis.

[0062] Therefore, the selection includes styrene-based macroporous strong acid cation exchange resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com