Method used for preparation of cyclized myrac aldehyde through catalytic selective cyclization of myrac aldehyde with supported molybdenum carbide

A molybdenum carbide and supported technology is applied in the field of preparing citrus aldehydes through the selective cyclization of citrus aldehydes catalyzed by supported molybdenum carbides. Low cost, high activity and selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Mo 2 C / AC(Mo 2 C is molybdenum carbide, and AC is activated carbon) The specific preparation method is as follows:

[0017] Ammonium molybdate was dissolved in water so that the mass concentration of ammonium molybdate was 13.3mg / ml. Then, the solution was impregnated with activated carbon support (AC) by the method of equal volume impregnation. After oven drying at 120 °C for 12 h, the catalyst precursor was placed in H 2 The temperature-programmed carbothermal reaction was carried out in the atmosphere. The specific reaction process was as follows: 1.0g precursor was heated from room temperature to 400°C in a quartz reaction tube for 1h, then raised to 700°C at 1°C / min and kept for 1h for carbonization. The hydrogen flow rate was 60ml / min. A molybdenum carbide loading of 1 wt% Mo 2 C / AC catalyst.

[0018] Other conditions remain the same, only change the concentration of ammonium molybdate in the impregnating solution to obtain catalysts with different loadings ...

Embodiment 2

[0020] Molybdenum carbide was supported on alumina, silica, titania, zirconia, titania, silica-alumina molecular sieve, and phosphorus-aluminum molecular sieve to prepare supported molybdenum carbide catalyst Mo 2 C / B (B is a porous carrier, which is activated carbon, alumina, silica, zirconia, titania, silicon-aluminum molecular sieve, phosphorus-aluminum molecular sieve). The catalyst preparation process is similar to that of Example 1, except that the carriers are alumina, silica, zirconia, titania, silica-alumina molecular sieves, and phosphorus-aluminum molecular sieves. At the same time, the carbonization gas is changed from hydrogen to CH 4 / H 2 (Volume ratio 1:4), molybdenum carbide loading in the catalyst is 2wt%, thus obtaining six catalysts in which molybdenum carbide is loaded on alumina, silica, zirconia, titania, silica-alumina molecular sieve, and phosphorus-aluminum molecular sieve .

Embodiment 3-18

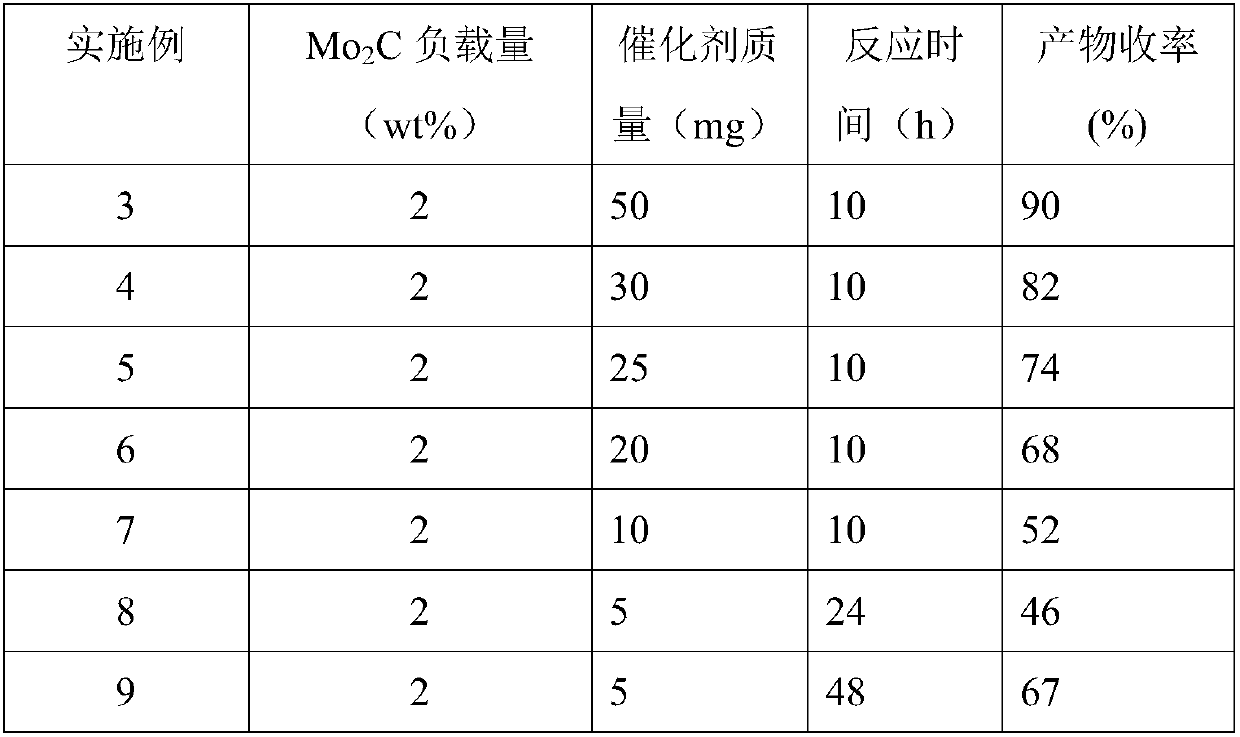

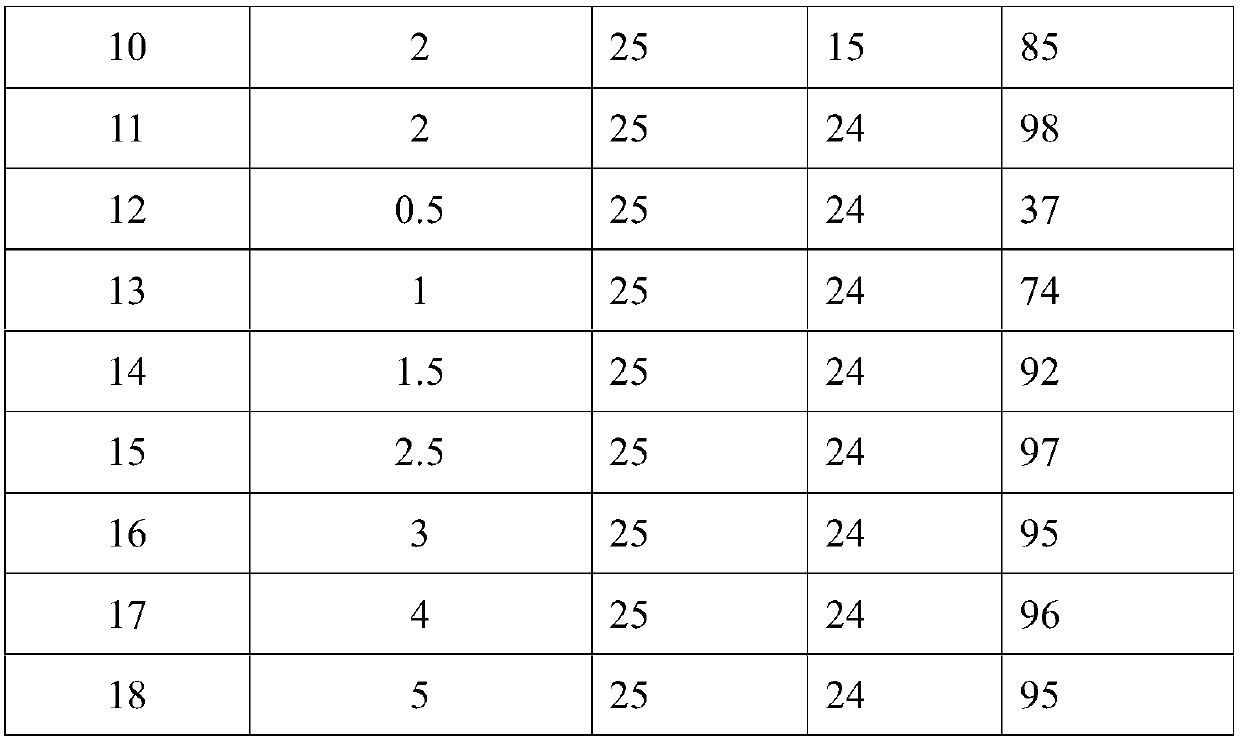

[0022] Mo 2 C / AC catalyzes the selective cyclization of para-citrus aldehyde to prepare cyclic citrus aldehyde: 5g para-citrus aldehyde, 50ml water, and Mo of a certain quality (see Table 1) 2 C / AC catalysts were added to the reactor respectively, replaced with nitrogen five times, the initial pressure of nitrogen was 0.1MPa, the temperature was controlled at 25°C, and the stirring reaction was carried out at a speed of 1000 rpm for 0.5-24h. Stand still for 10 minutes after the completion of the reaction, filter the supernatant and take a sample for analysis. Qualitative analysis of the product was carried out by GC-MS technology and standard sample control, and quantitative analysis was realized by gas chromatography internal standard method. The reaction results are shown in Table 1.

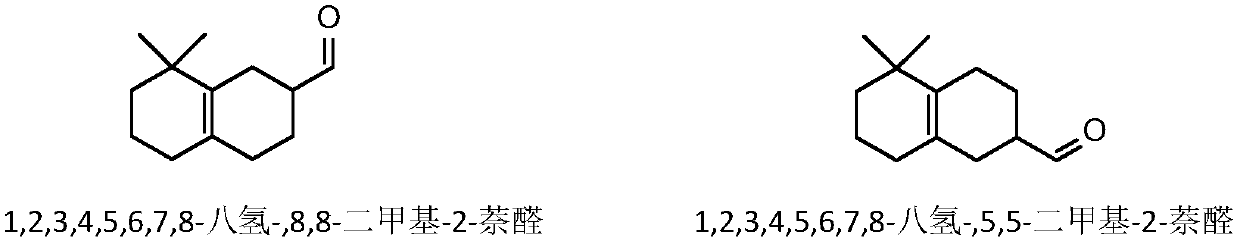

[0023] Table 1 Mo under different conditions 2 C / AC Catalyzed 4-(4-Methyl-3-pentenyl)-3-Cyclohexenal (P-Citral)

[0024] The results of the cyclization reaction to form 1,2,3,4,5,6,7,8-oct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com