Composite rock slice slurry and preparation method thereof

A technology of composite rock slices and slurry, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of spraying gun blocking, thick stacking, and easy breakage, and achieve improved mechanical properties, good storage stability, and short curing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

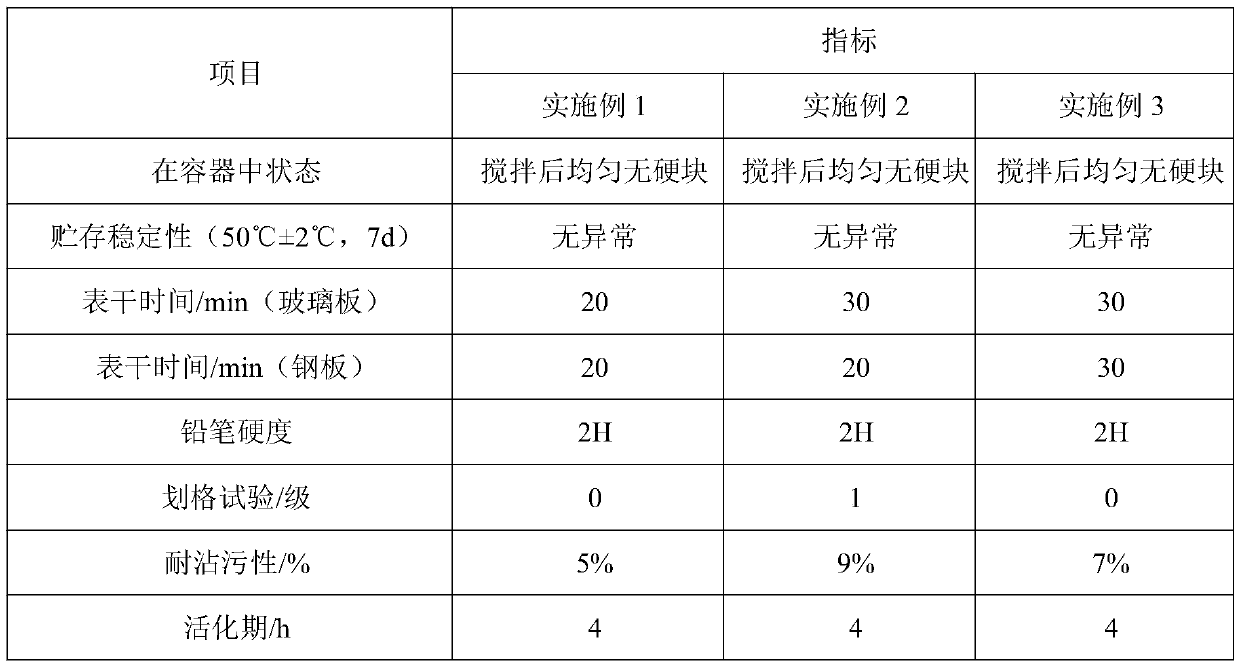

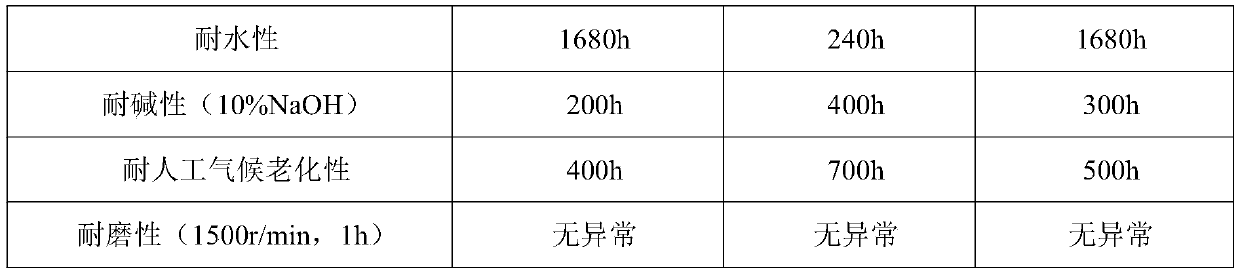

Examples

preparation example Construction

[0039] Embodiments of the present invention also provide a method for preparing composite slab slurry, comprising the steps of:

[0040] (1) mix the soaked pigment evenly with an orienting agent and a coupling agent to obtain a pigment slurry;

[0041] (2) mixing the soaked zeolite powder with a wetting agent and a hydrophobic agent evenly to obtain a zeolite liquid;

[0042] (3) Mix the pigment slurry, zeolite liquid and water-based hydroxyacrylic acid dispersion evenly to obtain component A; mix component A and component B containing water-dispersible isocyanate curing agent according to the weight ratio of 5 to 7:1 and mix evenly , get the finished product.

[0043] In the present invention, both the pigment and the zeolite powder are soaked in the co-solvent for 8-12 minutes, and then the subsequent treatment is carried out.

[0044] In the present invention, after the soaked pigment, orientation agent and coupling agent in step (1) are mixed, they are stirred at 300-500...

Embodiment 1

[0052] The present embodiment provides a composite slab slurry, comprising the following components:

[0053] Component A: 6 parts of pearlescent pigment, 0.5 part of coupling agent UP-105 isopropyl trioleate acyloxy titanate, 8 parts of co-solvent tripropylene glycol n-butyl ether, 0.3 part of directional agent BYK-8421, water-based hydroxyl Acrylic Dispersion 855160 parts, preservative Nipacide BIT 10F 1.6 parts, wetting agent BYK-348 0.5 parts, anti-sedimentation agent attapulgite 4 parts, zeolite powder 10 parts, defoamer Dehydran SE 2 1 part, hydrophobic agent Ombrelub RA 0.5 parts, Add water to 100 parts.

[0054] Component B: 80 parts of water dispersible isocyanate curing agent Bayhydur-305 and 20 parts of acetone.

[0055] The composite slab slurry is prepared by the following method:

[0056] (1) Add the pearlescent pigment to 4 parts of tripropylene glycol n-butyl ether and soak for 10 minutes, add BYK-8421 and UP-105 isopropyl trioleic acid acyloxy titanate to ...

Embodiment 2

[0061] The present embodiment provides a composite slab slurry, comprising the following components:

[0062] Component A: 10 parts of pearlescent pigment, 0.75 parts of coupling agent UP-101 isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate, 15 parts of co-solvent diethylene glycol monobutyl ether , Orienting agent carboxymethyl cellulose acetate butyrate 0.6 parts, water-based hydroxyacrylic acid dispersion 2033 30 parts, preservative Nipacide CFX 2 3 parts, wetting agent Raybo 62 0.2 parts, anti-settling agent B-100K 8 parts, zeolite powder 20 parts, defoamer BYK-1711 2 parts, hydrophobic agent Perenol HF200 0.3 parts, Add water to 100 parts.

[0063] Component B: Water-dispersible isocyanate curing agent 268 70 parts and propylene glycol methyl ether acetate 30 parts.

[0064] The composite slab slurry is prepared by the following method:

[0065] (1) Add the pearlescent pigment to 6 parts of diethylene glycol monobutyl ether and soak for 10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com