Method for preparing seed medium for fermenting citric acid, medium for fermenting citric acid and citric acid from whole starch

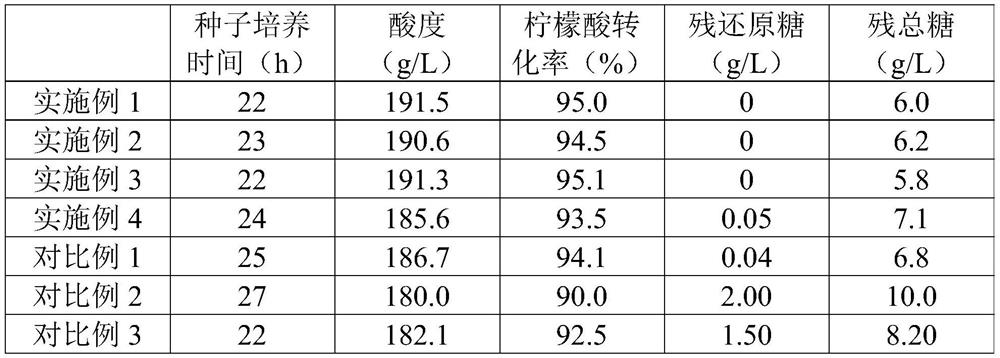

A technology for fermenting citric acid and whole starch, which is applied in the field of fermenting citric acid and citric acid, and can solve the problems of unstable quality, high residual sugar and long fermentation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033]The preparation method of the starch slurry can adopt various conventional methods known to those skilled in the art, for example, mixing starch with water to obtain a starch slurry, and prepare a starch slurry with a starch concentration of 15-35% by weight.

[0034]According to the present invention, in step (2), the addition amount of the added nitrogen source can be changed within a wide range, as long as it can meet the requirements of the fermentation strain for the nitrogen source. In general, the added amount of the nitrogen source can be 0.01-0.2% by weight, preferably 0.05-0.1% by weight, based on the nitrogen element. The types of the supplementary nitrogen source are well known to those skilled in the art. For example, the supplementary nitrogen source may be one or more of urea, ammonium sulfate, ammonium nitrate, and corn steep liquor.

[0035]More preferably, the nitrogen source is corn steep liquor. In this preferred case, the pH value of the starch liquefaction solu...

Embodiment 1

[0066]This example is used to illustrate the preparation method of citric acid provided by the present invention

[0067]1) Sizing: Sizing with water and whole corn starch to obtain a starch slurry, and the amount of water added is such that the slurry concentration of the starch slurry is 20% by weight.

[0068]2) Enzymatic hydrolysis: mix the starch slurry obtained in step (1) with amylase (Novozymes, α-amylase, this amylase in the embodiments of the present invention) at 50°C to obtain a mixture (relatively The amount of amylase is 15 enzyme activity units per gram of dry starch, and the mixture is sprayed with steam at 240°C in an ejector (the weight ratio of steam to the mixture is 0.04:1), and the contact time is For 3 seconds, the temperature of the mixture after contact with steam was 100°C, the pH value was adjusted to 5.3, and the temperature was maintained for 70 minutes.

[0069]3) Flash vaporization: flash vaporize the above-mentioned mixture after contact with steam (vacuum deg...

Embodiment 2

[0075]This example is used to illustrate the preparation method of citric acid provided by the present invention

[0076]1) Sizing: Sizing with water and corn starch to obtain a starch slurry, and the amount of water added is such that the slurry concentration of the starch slurry is 15% by weight.

[0077]2) Enzymatic hydrolysis: mix the starch slurry obtained in step (1) with amylase (Novozymes, α-amylase, this amylase in the embodiments of the present invention) at 50°C to obtain a mixture (relatively The amount of amylase is 10 enzyme activity units per gram of dry starch, and the mixture is sprayed with steam at 230°C in an ejector (the weight ratio of steam to the mixture is 0.04:1), and the contact time is For 3 seconds, the temperature of the mixture after contact with the steam was 91°C, the pH value was adjusted to 5.4, and the temperature was maintained for 60 minutes.

[0078]3) Flash vaporization: flash vaporize the above-mentioned mixture after contact with steam (vacuum degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com