A kind of method for growing nano metal palladium particles on the surface of polymer film

A polymer film and nano-metal technology, applied in nanotechnology, metal material coating process, coating and other directions, can solve problems such as high cost and highly complex equipment, and achieve cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

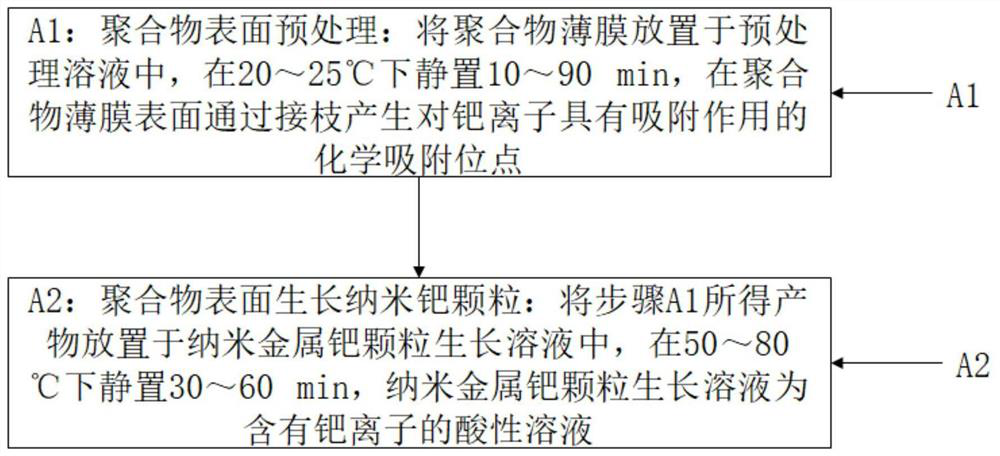

[0047]Seefigure 1 , A method for growing nano-metal palladium particles on the surface of a polymer film. The substrate of the polymer film used is silicon or other similar substrates. The polymer film used can be polymethylmethacrylate (PMMA) or polymethacrylic acid ( PMAA), polymethacrylimide (PMI), polyethylene terephthalate (PET), polyamide (PA), polypropylene (PP), polyvinyl chloride (PVC), polyvinyl alcohol ( PVA) and other organic films, the method includes:

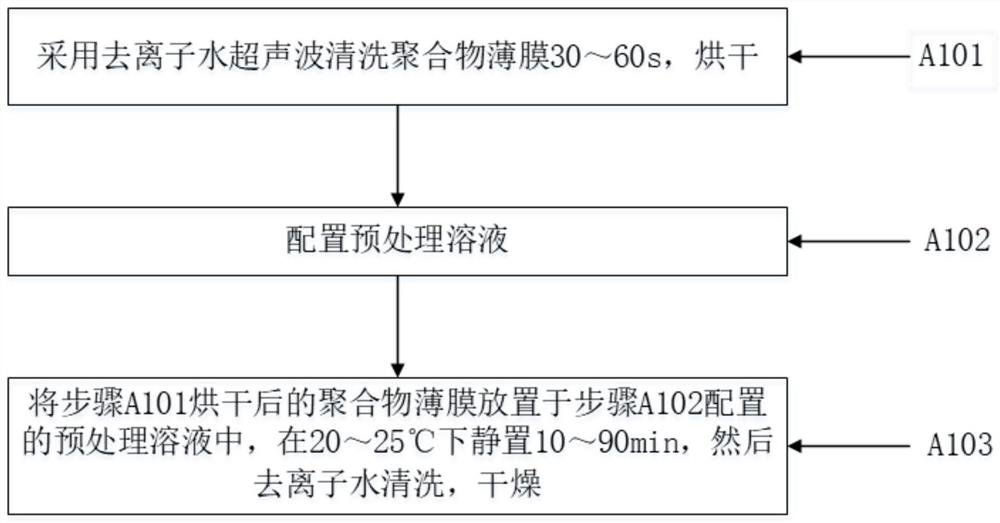

[0048]A1: Pretreatment of polymer surface: Place the polymer film in the pretreatment solution and let it stand at 20~25℃ for 10~90 minutes; the pretreatment solution contains grafting raw materials that can be grafted to the polymer surface, pretreatment In the process, a chemical adsorption point that can adsorb palladium ions is grafted on the surface of the polymer film;

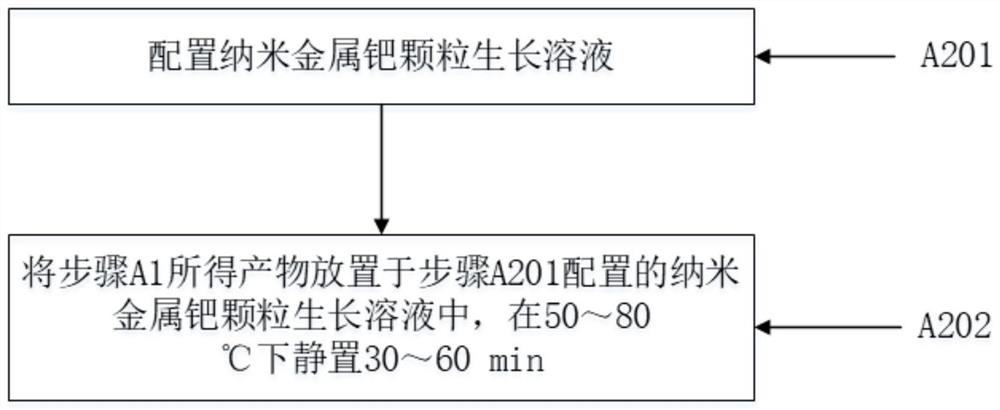

[0049]A2: Growth of nano-palladium particles on the polymer surface: Place the product obtained in step A1 in a nano-metal palladium particle growth so...

Embodiment 2

[0066]The steps of growing nano-palladium particles on the surface of polymethacrylic acid (PMAA) film are:

[0067]1. First prepare the PMAA / Si matrix; use acetone, alcohol and deionized water to ultrasonically clean the silicon wafer, then immerse it in an HF solution with a volume ratio of 5% for Si-H treatment for 3 minutes, then place the silicon wafer In the prepared grafting solution, the grafting reaction is carried out at 25°C for 30 minutes, then ultrasonically cleaned with deionized water and dried to obtain a PMAA / Si matrix, such asFigure 6 It can be seen that a layer of PMAA film is grafted on the silicon substrate. The above grafting solution is prepared as follows: first add 50 mL of deionized water into a beaker, and then add 0.1 g of sodium lauryl sulfate, 1 mL of fluoroboric acid, 0.5 mL of hydrofluoric acid, and 2 mL of formaldehyde under magnetic stirring. Acrylic acid and 0.1 g of p-nitrobenzene tetrafluoroborate diazonium salt, stir until clear.

[0068]2. Configure ...

Embodiment 3

[0078]The steps of growing nano-palladium particles on the surface of polymethyl methacrylate (PMMA) film are:

[0079]1. First prepare the PMMA / Si matrix; use acetone, alcohol and deionized water to ultrasonically clean the silicon wafer, immerse it in an HF solution with a volume ratio of 5% for Si-H treatment for 3 minutes, and place the silicon wafer In the configured grafting solution, the grafting reaction is carried out at 25° C. for 30 minutes, ultrasonically cleaned with deionized water and dried to obtain a PMMA / Si matrix. The above grafting solution is prepared as follows: first add 100 mL of deionized water into a polytetrafluoroethylene container, and then add 0.2 g of sodium lauryl sulfate, 2 mL of fluoroboric acid, 1 mL of hydrofluoric acid, 4mL methyl methacrylate and 0.2g p-nitrobenzene tetrafluoroborate diazonium salt, stir until clear.

[0080]2. Configure the pretreatment solution:

[0081]

[0082]3. Place the sample obtained in step 1 vertically in the pretreatment solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com