A method for reactive distillation to continuously produce 3-methyl-3-penten-2-one

A technology of reactive distillation and reactive distillation column, which is applied in the field of chemical synthesis, can solve the problems of low utilization rate of raw materials, difficult recovery of catalysts, large amount of waste water, etc., achieves high conversion rate and selectivity, and improves conversion rate and selectivity. , reduce the effect of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

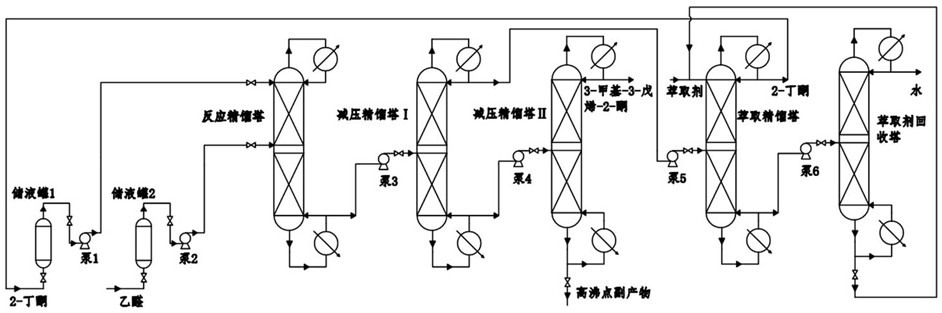

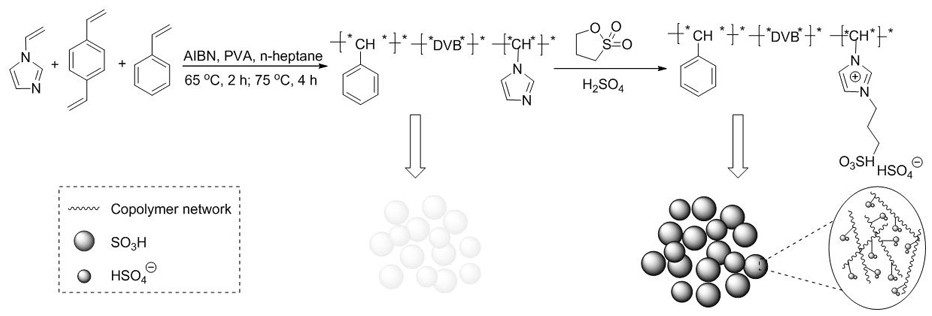

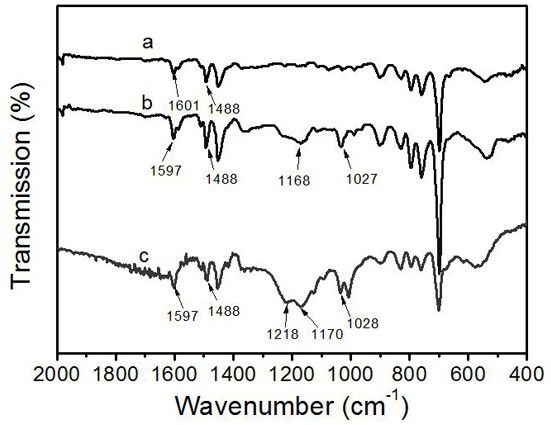

Method used

Image

Examples

Embodiment 1

[0034] Reactive distillation tower reaction section filled new microspheallopolymer ionic liquid P (VB-VS) HSO 4 The filler height is 3 m, the feed molar ratio of 2-butanone and acetaldehyde is 6: 1, which is filled with nitrogen to operate the rectification tower to operate the pressure of 0.2 MPa, and the temperature of the reaction rectification column is 75 ° C, The tower is fully refluxed; the reduced pressure rectification tower I reflow ratio is 3, the operating pressure is 50 kPa; the pressure is 10 kPa in the decompression rectification column, the reflow ratio is 2; the extraction rectification column is operated at normal pressure, the reflow ratio is 1.2; Extractant recovery tower operating pressure atmospheric, reflow ratio of 2.2, and extractant is benzene.

[0035] In the present embodiment, the conversion of acetaldehyde is 99.31%, and the yield of 3-methyl-3-pentene-2-ketone is 90.23%, and the purity is 98.82%.

Embodiment 2

[0040] Reactive distillation tower reaction section filled new microspheallopolymer ionic liquid P (VB-VS) HSO 4 The filling height is 3 m, and the feed molar ratio of 2-butanone and acetaldehyde is 8: 1, and the rectification tower is filled with a rectification column to reach 0.2 MPa, and the temperature of the reaction rectification column is 75 ° C, The tower is fully refluxed; the reduced pressure rectification tower I reflow ratio is 6, the operating pressure is 60 kPa; the pressure-reducing rectification column II tower operates 10 kPa, the reflow ratio is 2; the extraction rectification tower is operated at normal pressure, reflow ratio is 1.2; Extractant recovered in the tower operation pressure, reflow ratio of 2.2, and the extractant is dimethyl sulfoxide.

[0041] In the present embodiment, the conversion rate of acetaldehyde is 99.65%, and the yield of 3-methyl-3-pentene-2-ketone is 92.35%, and the purity is 99.32%.

Embodiment 3

[0046] Reactive distillation tower reaction section filled new microspheallopolymer ionic liquid P (VB-VS) HSO 4 The filling height is 4m, the feed molar ratio of 2-butanone and acetaldehyde is 10: 1, which is filled with nitrogen to operate the rectification tower to operate the pressure of 0.2 MPa, and the temperature of the reaction distillation column is 75 ° C, all The tower is fully refluxed; the reduced pressure rectification tower I reflow ratio is 8, the operating pressure is 65kPa; the pressure-reducing rectification column II tower operates 10 kPa, the reflow ratio is 2; the extraction rectification column is operated at pressure, the reflow ratio is 1.2; Extractant recovered in the tower operating pressure, reflow ratio of 2.2, and the extractant is chloroform.

[0047] In the present embodiment, the conversion of acetaldehyde is 99.87%, and the yield of 3-methyl-3-pentene-2-ketone is 93.52%, and the purity is 99.63%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com