Organic polymer keeping morphology of metal-organic frameworks (MOFs), and preparation method and application of organic polymer

A polymer and organic technology, applied in various application fields, can solve the problems of unstable appearance or macrostructure of MOFs, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 0.76g of p-phenylenediamine and 1.69g of copper nitrate were dissolved in ethanol, and the mixed solution was transferred to a reaction kettle, and reacted by solvothermal at 80°C for 24h, and centrifuged and dried to obtain a poly-p-phenylenediamine product that maintained the morphology of MOFs. The precipitate in the initial mixture was taken out (the reaction time was considered to be 1min), and recorded as the product of 1min, and then the product of solvothermal time of 30min and 1h was also collected to study its formation process. At the same time, the obtained poly-p-phenylenediamine is heat-treated under an inert gas atmosphere at 600° C. to obtain a carbon material, which is used as a negative electrode material for a lithium-ion battery.

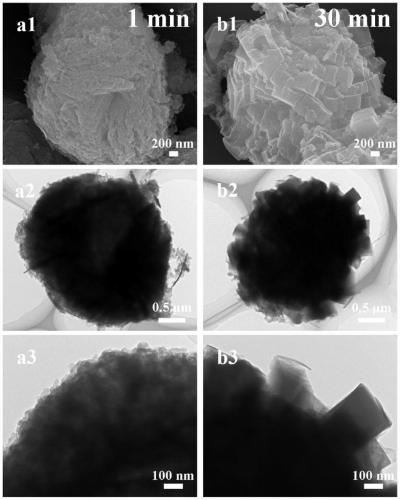

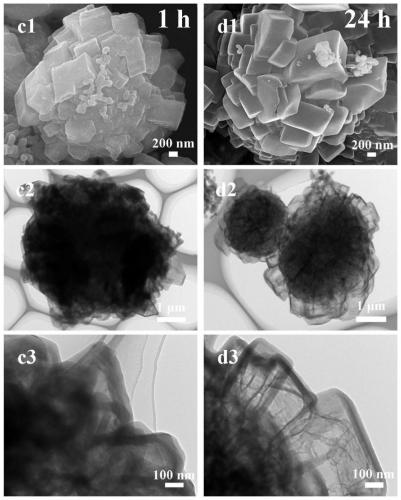

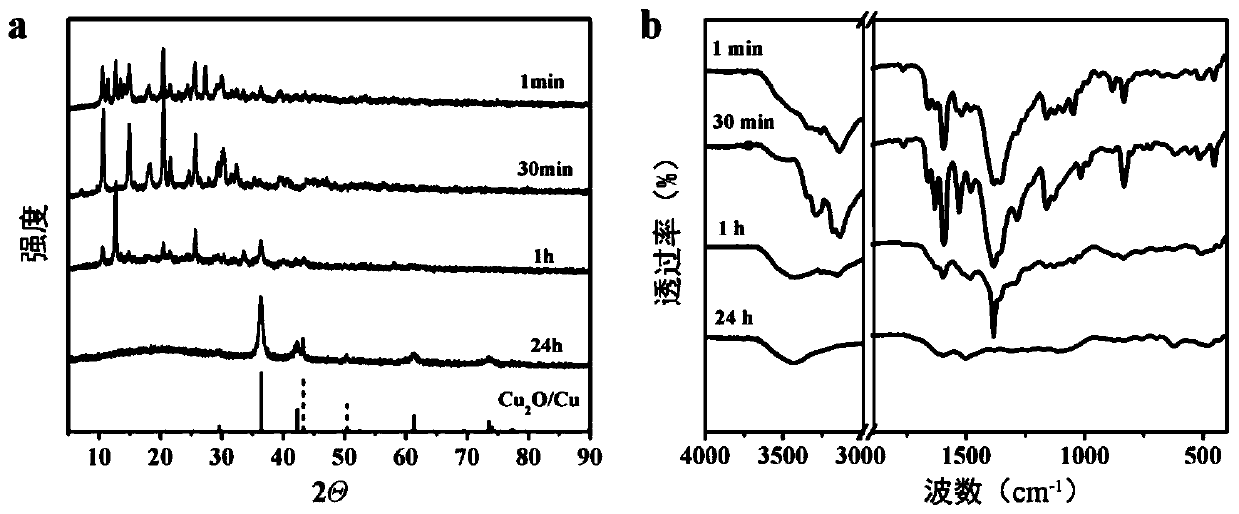

[0027] as attached figure 1 As shown by the scanning electron microscope, when p-phenylenediamine and copper nitrate are mixed together, a spherical product will be formed rapidly, and small particles can be seen evenly di...

Embodiment 2

[0031] 0.76g of o-phenylenediamine and 2.04g of cobalt nitrate were dissolved in ethanol, and the mixed solution was transferred to a reaction kettle, and reacted by solvent heating at 120°C for 24 hours, and centrifuged and dried to obtain a poly-o-phenylenediamine product that maintained the morphology of MOFs. The obtained poly-o-phenylenediamine is heat-treated at 700° C. to obtain a carbon material, which is used as a negative electrode material for a sodium-ion battery.

[0032]At the beginning of the reaction, o-phenylenediamine and cobalt nitrate undergo a coordination reaction to form a sheet-like metal-organic framework. With the progress of the solvothermal reaction, o-phenylenediamine self-crosslinks to form nano-sheet poly-o-phenylenediamine. After high-temperature pyrolysis treatment, porous carbon nanosheets were obtained, which were used as anode materials for sodium-ion batteries, and their rate performance was tested, as shown in the appendix. Figure 5 shown...

Embodiment 3

[0034] 0.76g of m-phenylenediamine and 1.74g of ferric nitrate were dissolved in ethanol, the mixed solution was transferred to the reaction kettle, the solvothermal reaction was performed at 150 °C for 24 h, and the poly-m-phenylenediamine product with the morphology of MOFs was obtained by centrifugal drying. The obtained poly-m-phenylenediamine was heat-treated at 800°C to obtain a carbon material, which was used as an electrode material for a supercapacitor.

[0035] At the beginning of the reaction, m-phenylenediamine and ferric nitrate undergo a coordination reaction to form a sheet-like metal-organic framework with interwoven fibers. The morphology of the organic framework was maintained, and the obtained polymer was pyrolyzed to obtain a carbon sheet with interwoven fibers, which was used as an electrode material for supercapacitors, and its cycle performance was tested. The results are as follows. Image 6 shown at 1A g -1 After 5000 cycles at the same current densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com